A method for hydrolyzing whey protein and preparing peptone with compound enzyme

A whey protein and whey protein hydrolysis technology, applied in the direction of fermentation, etc., can solve the problems of unreasonable amino acid composition, low protein content, and low nutritional value of peptone products.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

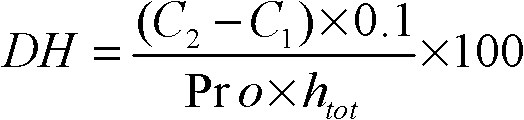

Method used

Image

Examples

Embodiment 1

[0045] The whey protein is prepared into a solution of 8% by weight with water, and the solution is centrifugally defatted (5000r / min, 55°C, the processing capacity is 20t / h), and the defatted solution is incubated in a hot water bath at 80°C for 15 minutes , adjust the pH value of the defatted solution to 9.0 with 1mol / L aqueous sodium hydroxide solution; then, add the compound enzyme of alkaline protease and flavor protease, the total addition amount of compound enzyme is 5% of the weight of whey protein added, wherein the addition ratio of alkaline protease to flavor protease is 0.6:1; this solution is hydrolyzed at 55°C for 4.0 hours, and inactivated in a water bath at 85°C for 10 minutes , and then use the ultrafiltration membrane to filter the solution. The molecular weight and aperture of the ultrafiltration membrane is 200,000 Da. The working pressure of the ultrafiltration membrane is 0.40MPa, and the working pressure of the membrane is 0.05MPa. The temperature was 42...

Embodiment 2

[0048] Whey protein is prepared into a 2% by weight solution with water, and the solution is centrifugally degreased (5000r / min, 55°C, processing capacity is 20t / h), and the defatted solution is incubated in a hot water bath at 60°C for 10 minutes , adjust the pH value of the degreased solution to 8.0 with 1mol / L aqueous sodium hydroxide solution; It is 2% of the weight of the whey protein added when preparing the whey protein aqueous solution, wherein the addition ratio of alkaline protease and flavor protease is 0.4: 1; this solution is hydrolyzed under the condition of 50 ℃ for 3.0 hours, at 80 ℃ Under the condition of water bath inactivation for 10 minutes, then use the ultrafiltration membrane to filter the solution. The molecular weight and pore size of the ultrafiltration membrane is 50,000 Da, the working pressure of the ultrafiltration membrane is 0.30MPa, and the working pressure of the membrane is 0.20 MPa, the working temperature of the ultrafiltration membrane is ...

Embodiment 3

[0051] Whey protein is prepared into a 10% by weight solution with water, and the solution is centrifugally degreased (5000r / min, 55°C, processing capacity is 20t / h), and the defatted solution is kept in a hot water bath at 90°C for 20 minutes , adjust the pH value of the defatted solution to 10.0 with 1mol / L sodium hydroxide aqueous solution; It is 4% of the weight of the whey protein added when preparing whey protein aqueous solution, wherein the addition ratio of alkaline protease and flavor protease is 0.7: 1; Under the condition of water bath inactivation for 10 minutes, then use the ultrafiltration membrane to filter the solution. The molecular weight and aperture of the ultrafiltration membrane is 200,000 Da. The working pressure of the ultrafiltration membrane is 0.40MPa, and the working pressure of the membrane is 0.10 MPa, the working temperature of the ultrafiltration membrane is 50° C.; then the permeate is concentrated by a reverse osmosis membrane, and the concen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com