Bedding long drilling hole seam cutting and hole washing integral coal bed gas extraction method

A technology of long drilling and coalbed methane, which is applied in the direction of earthwork drilling, mining fluid, mining equipment, etc. It can solve the problems of not considering the structural characteristics of coal and rock mass, low, easy to deform when encountering water expansion, and difficult construction, etc. Achieve the effect of improving coal seam permeability, less damage to reservoir, and increasing coal bed methane drainage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

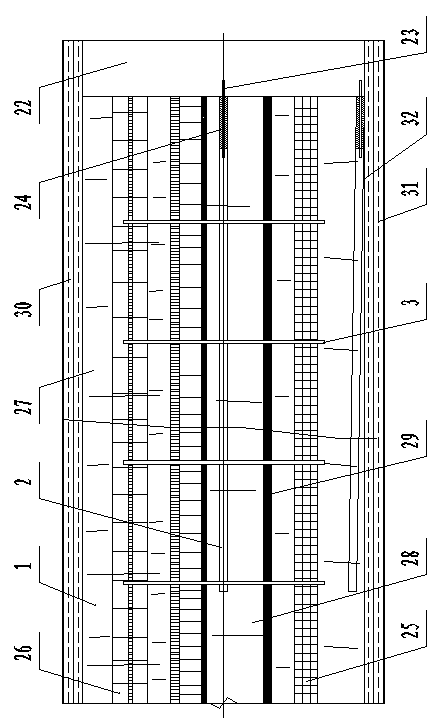

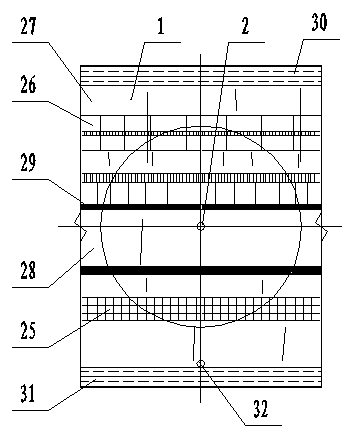

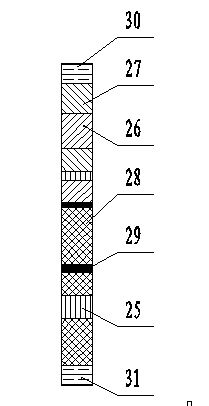

[0078] Coalbed methane extraction method integrated with bedding-long drilling, slotting and washing, refer to figure 1 , figure 2 Shown. The thickness of coal seam 1 in a certain area is 3m, and the length of the roadway is 800m. Between the two layers of gangue 29 in the middle of the coalbed methane drainage roadway 22 working face in coal seam 1, a thousand-meter drilling rig is used to drill the bedding-long borehole 2 in the direction of the pre-excavation roadway. Drilling 2 along the bedding with a diameter of φ96mm. After the drill hole reaches the predetermined depth, clean the drill pipe channel with clean water, withdraw the drill, rotate the drill pipe in situ at the design position of the first large vertical crack 3 at the bottom of the drill hole, increase the hydraulic pressure, open the nozzle 12 for seam making, and apply The high-pressure water jet vertical large crack cutting device cuts the vertical large crack 3 on the axis plane of the vertical long ...

Embodiment 2

[0080] Using multiple parallel bedding long boreholes 2 cutting vertical large fractures at radial intervals 3 methods to extract coalbed methane, refer to image 3 and Figure 4 Boreholes and vertical large fractures 3 are arranged in the schematic manner. The thickness of coal seam 1 of Shanxi Formation in a certain area is 3m, and the diameter of large vertical crack 3 is about φ2000mm. Between them, the distance between the bedding-long boreholes 2 is different according to the arrangement of the vertical large cracks 3 in the adjacent bedding-long boreholes 2 . The vertical large cracks 3 in the adjacent bedding-long boreholes 2 are arranged in a rectangular manner, that is, when they are aligned along the depth direction of the bedding-long boreholes 2, the distance between the bedding-long boreholes 2 may be 3 to 5 m (see image 3 ); the vertical large cracks 3 in the adjacent bedding long boreholes 2 are arranged in a triangle, that is, when the bedding long borehole...

Embodiment 3

[0082] When the thickness of the coal seam is 5-6m, 2-3 long boreholes 2 along the bedding can be arranged layer by layer on the same vertical plane, refer to Figure 6 , the layout of long boreholes 2 along the horizontal plane can be referred to Figure 4 or Figure 5 . The coal seam 1 of the Shanxi Formation in a certain area has a thickness of 5.8m. Two bedding long boreholes 2 are arranged on the same vertical plane with a distance of 2.5m. The distance between adjacent bedding long boreholes 2 on the horizontal plane is 5m. The diameter of the vertical large crack 3 in the layer-length borehole 2 is about φ2000mm, and the distance between two vertical large cracks 3 is 8-10m. Method is with embodiment 1. Then construct drainage boreholes 32 obliquely upwards at a slope of 5‰ below each bedding long borehole 2 near the bottom plate 31, and the distance between the drainage borehole 32 and the bedding long borehole 2 axis is 1.5~2d(d is the diameter of the vertical lar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com