Epitaxial structure of LED (Light Emitting Diode)

An epitaxial structure, p-type technology, applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problem of uneven distribution of current density, achieve the effects of improving luminous efficiency and reliability, convenient manufacture, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

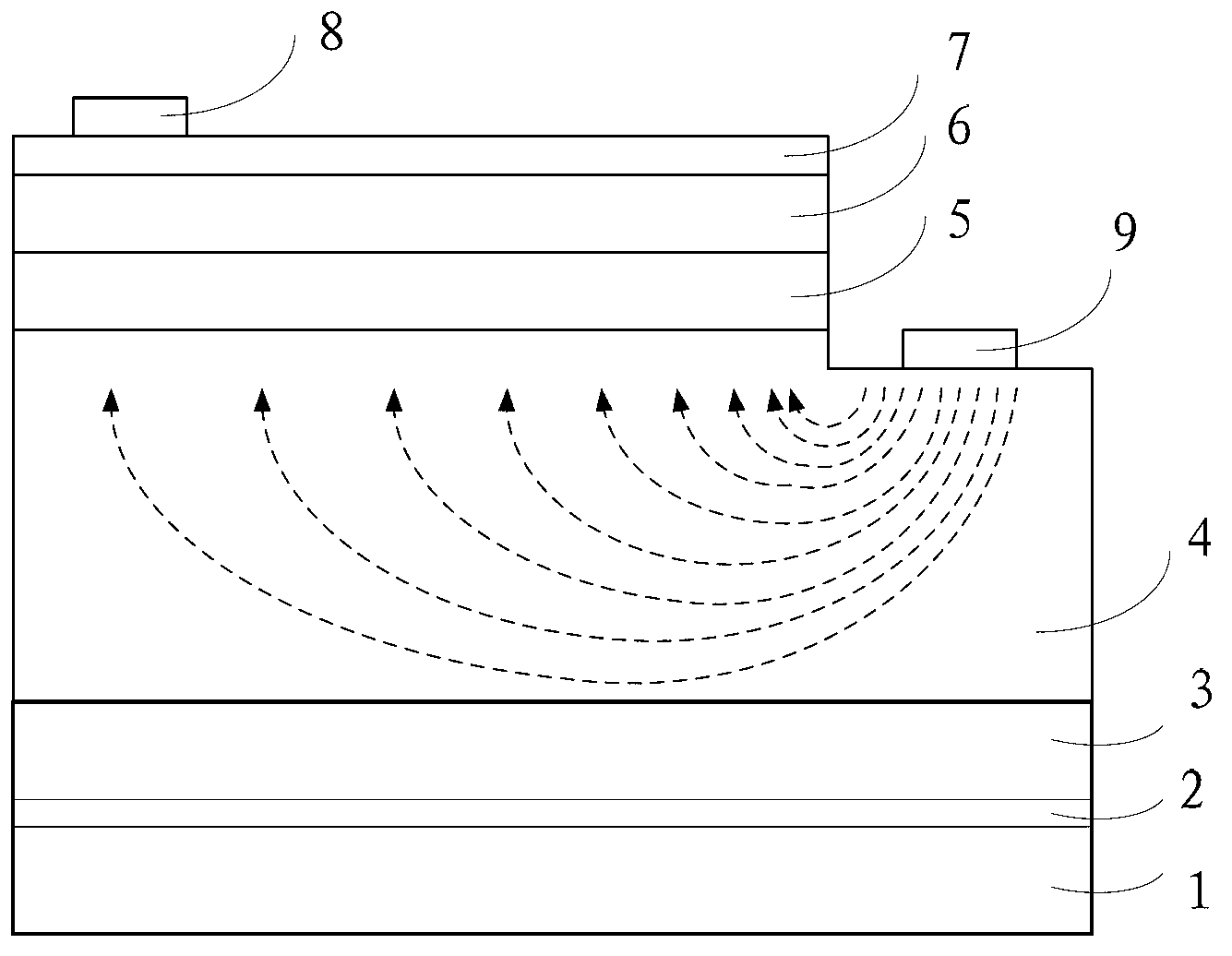

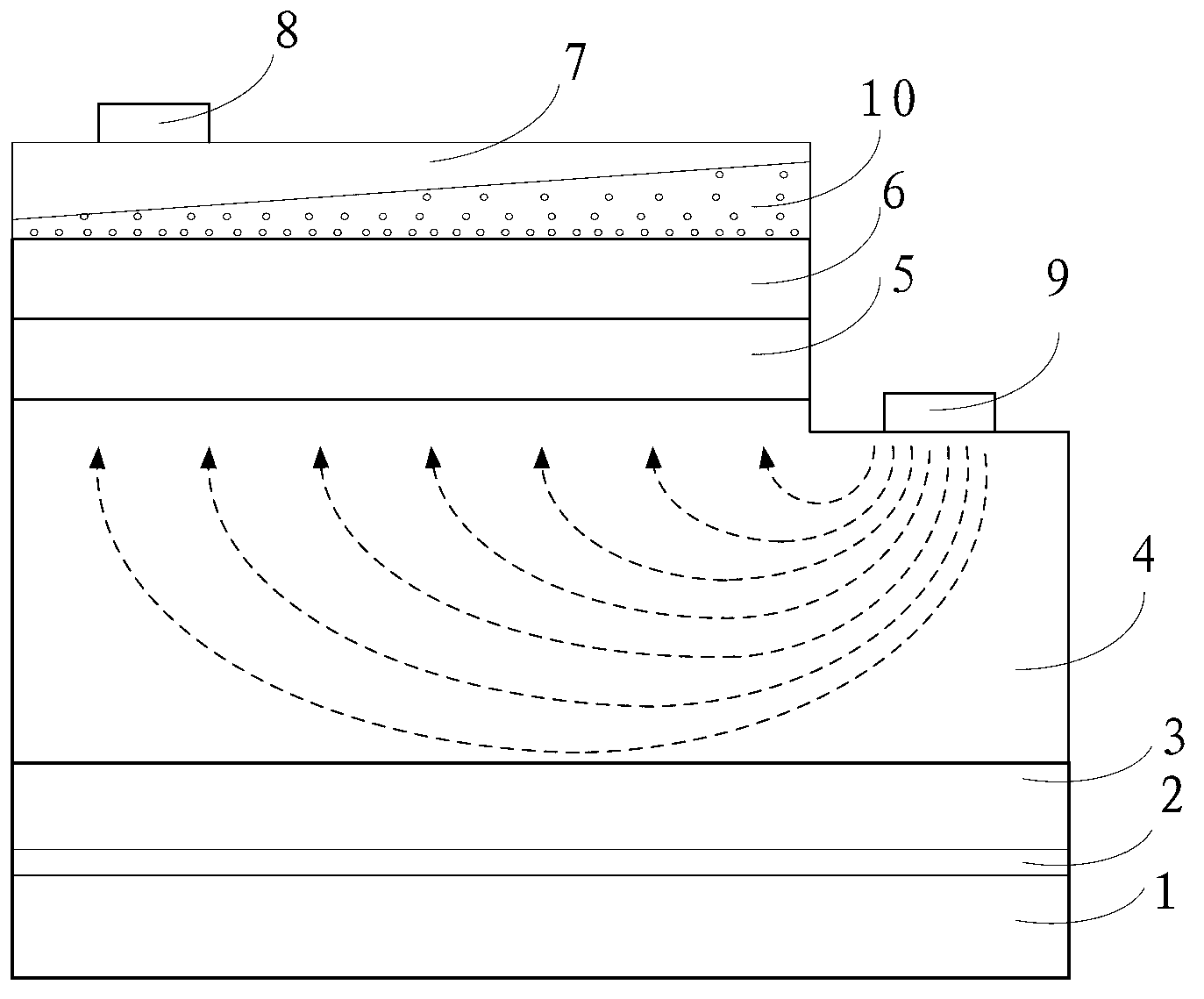

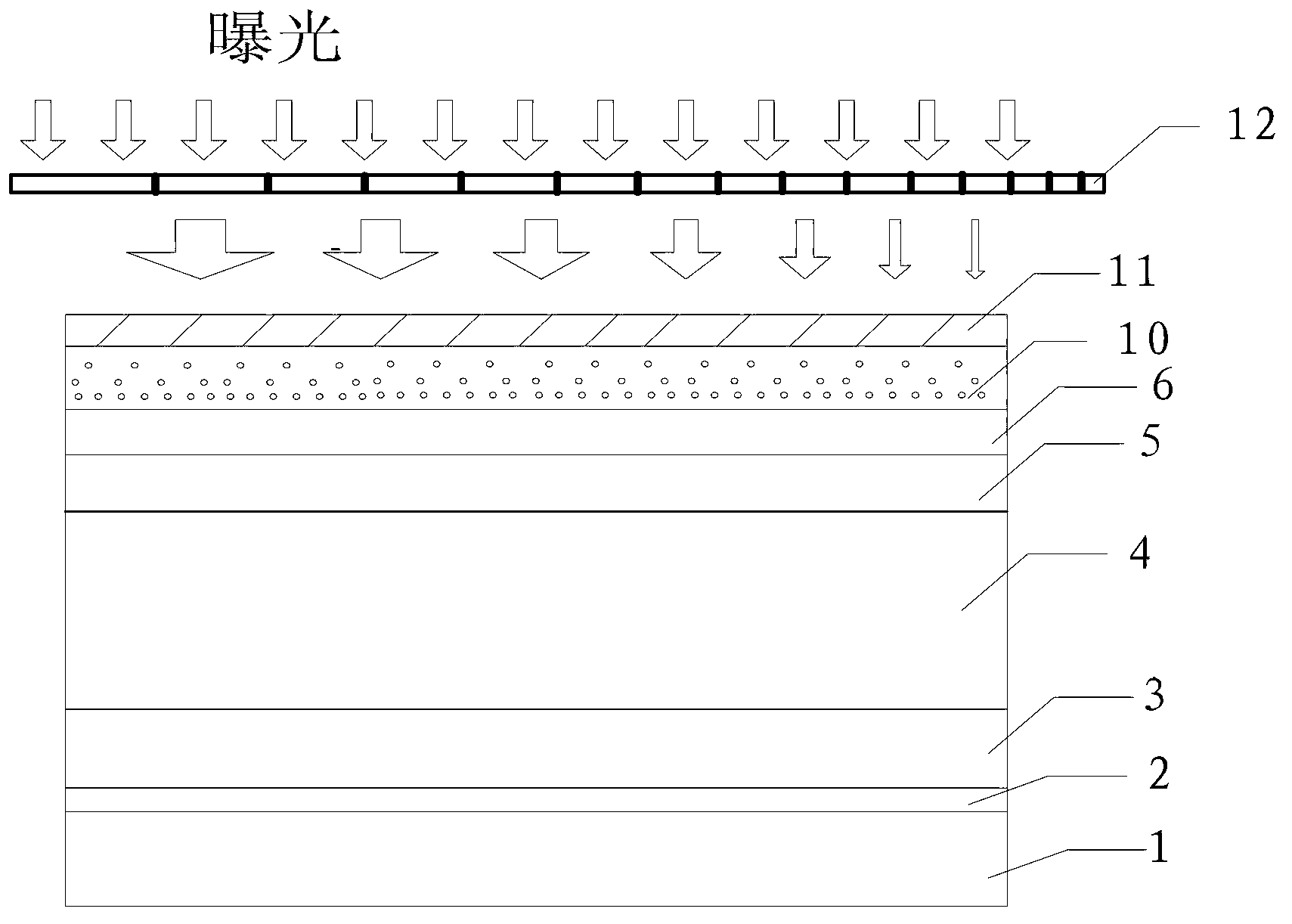

[0018] Such as figure 2 As shown, an LED epitaxial structure includes a substrate 1, a transition layer 2, a u-type gallium nitride layer 3, an n-type gallium nitride layer 4, a multi-quantum well layer 5, and a p-type gallium nitride layer 6 stacked in sequence. , ITO tin-doped indium oxide layer 7, p-type electrode 8 and n-type electrode 9 formed on the n-type gallium nitride layer, also includes a p-type contact layer 10, the p-type contact layer 10 is between p-type nitride Between the gallium layer 6 and the ITO tin-doped indium oxide layer 7, there is a wedge-shaped structure, and the hole concentration of the p-type contact layer 10 gradually changes, and the hole concentration near the p-type gallium nitrid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com