Chromate-free coated metal plate

A metal plate and coating technology, which is applied to metal layered products, metal material coating processes, devices for coating liquids on surfaces, etc., can solve problems such as insufficient damage resistance, and achieve low price and damage resistance. excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

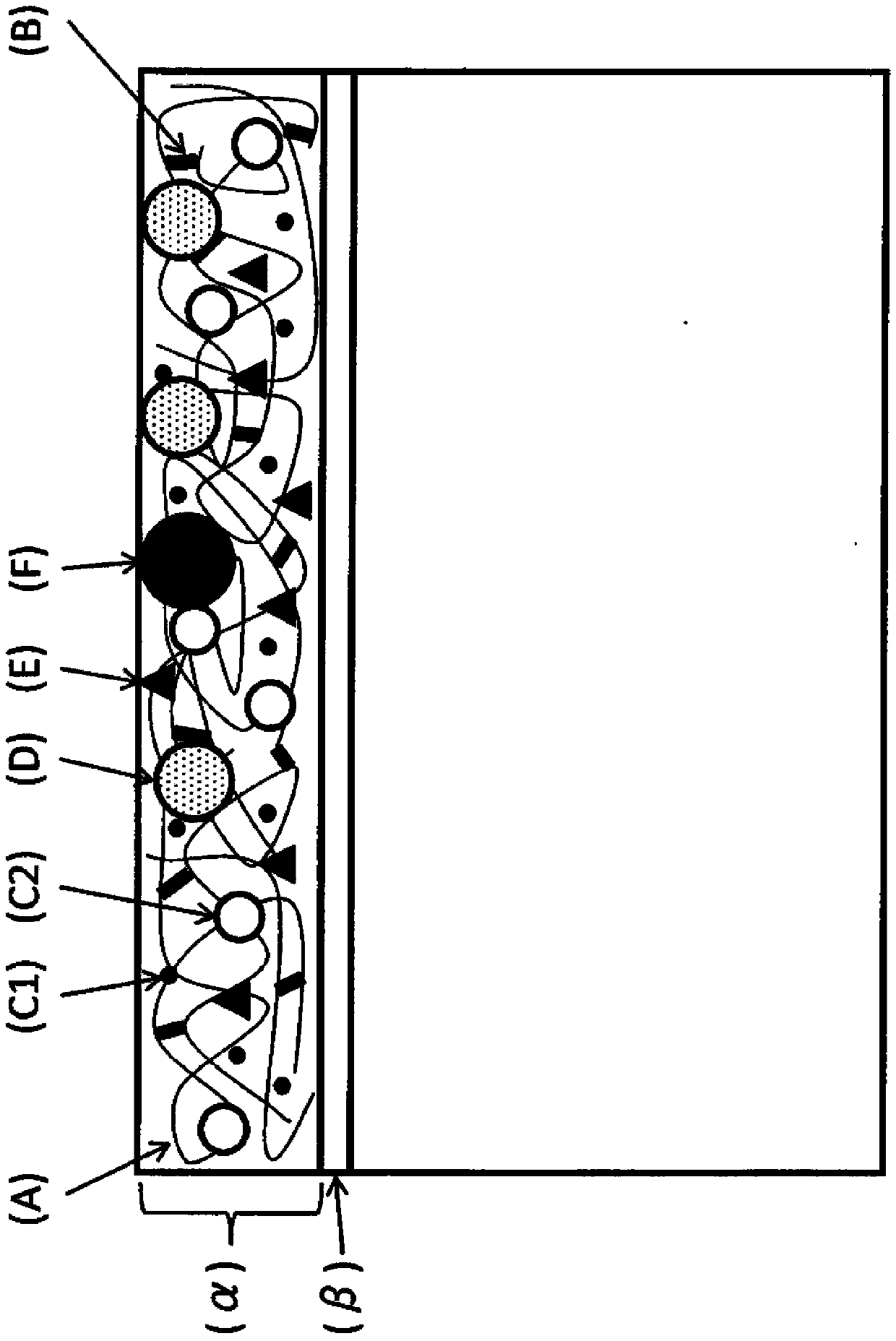

Method used

Image

Examples

Embodiment

[0150] Embodiments of the present invention will be described below. However, the present invention is not limited by these Examples.

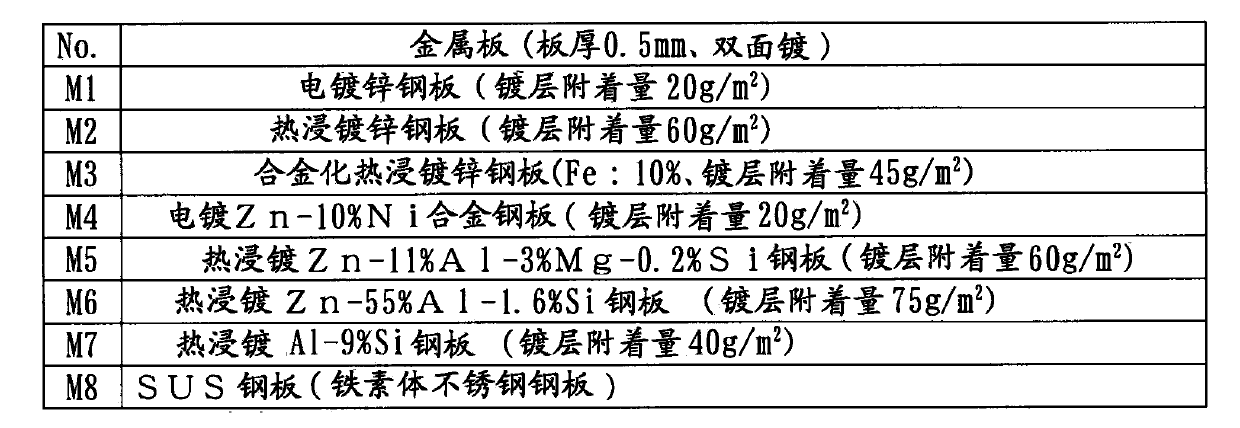

[0151] (1) metal plate

[0152] Table 1 shows the types of metal plates used. A mild steel plate with a plate thickness of 0.5 mm was used as the base material of the plated metal plate. The SUS plate uses a ferritic stainless steel plate (steel composition: C: 0.008 mass%, Si: 0.07 mass%, Mn: 0.15 mass%, P: 0.011 mass%, S: 0.009 mass%, Al: 0.067 mass%, Cr : 17.3% by mass, Mo: 1.51% by mass, N: 0.0051% by mass, Ti: 0.22% by mass, the balance being Fe and unavoidable impurities). The surface of the metal plate is degreased with alkali, washed with water and dried before use.

[0153] Table 1

[0154]

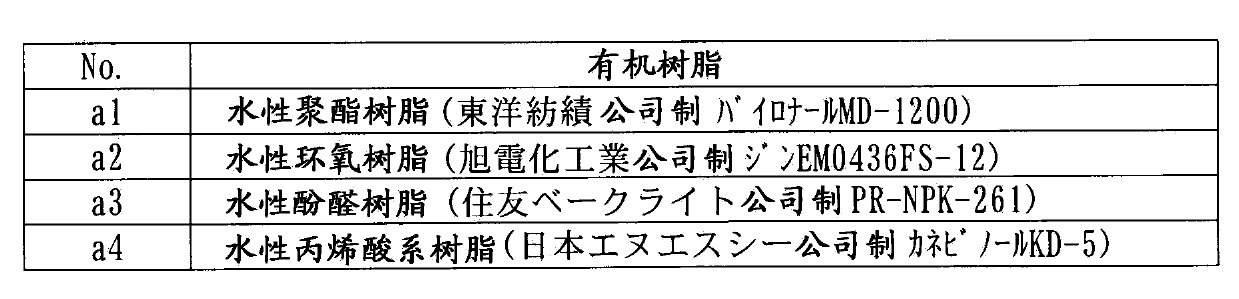

[0155] (2) base treatment layer

[0156] The coating agent used to form the surface treatment layer was blended with an organic resin (Table 2), a silane coupling agent (Table 3), and a polyphenol compound (Table 4) in the amount shown ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com