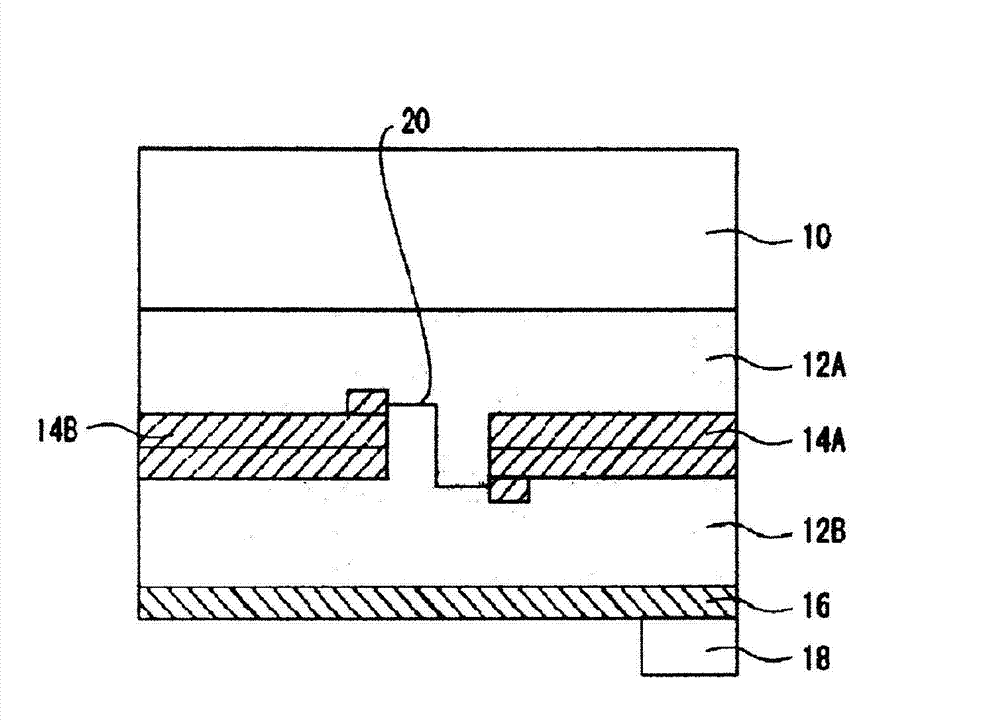

Solar cell sealing material and solar cell module produced by using same

A technology for solar cells and packaging materials, applied in electrical components, sealing devices, circuits, etc., can solve the problems of solar cell circuit corrosion, interface peeling, adverse effects, etc. and excellent heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

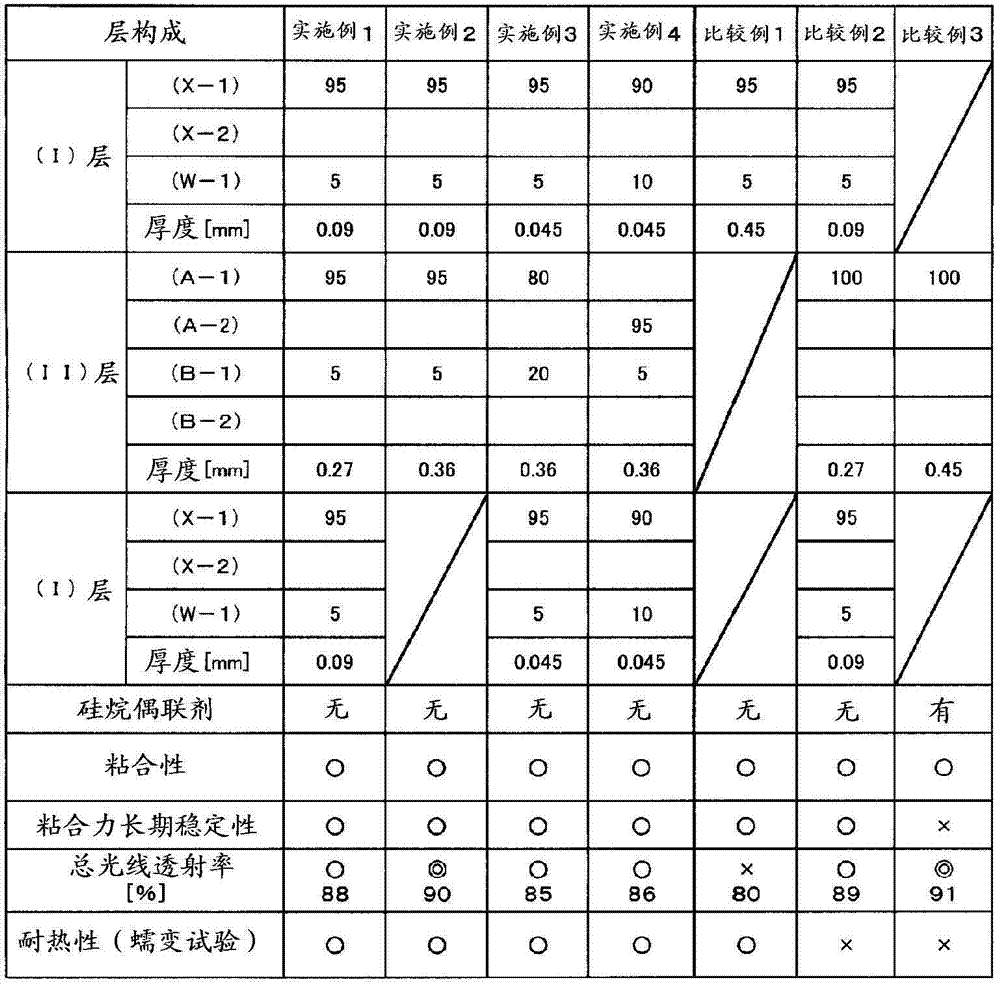

[0229] A resin composition obtained by mixing (X-1) and (W-1) at a mass ratio of 95:5 was used in the (I) layer, and (A-1) was used as the (II) layer The resin composition mixed with (B-1) at a mass ratio of 95:5 was obtained by using double The T-die method of the shaft extruder, after co-extrusion molding under the condition of resin temperature 180~220 ℃, the casting roll is used for rapid film forming at 20 ℃, and the thickness of each layer is obtained as (I) / (II) / (I)=0.09mm / 0.27mm / 0.09mm sheet. Table 1 shows the results of evaluating various properties using the obtained sheet.

Embodiment 2)

[0231] In Example 1, except that the lamination structure is changed to (I) layer / (II) layer, and the thickness of each layer is (I) / (II)=0.09mm / 0.36mm, the same as in Example 1 Tablets were obtained in the same manner. Table 1 shows the results of evaluating various properties using the obtained sheet.

Embodiment 3)

[0233] In Example 1, a resin composition obtained by mixing (A-1) and (B-1) at a mass ratio of 80:20 was used as the (II) layer, and the thickness of each layer was (I) / ( II) / (I)=0.045mm / 0.36mm / 0.045mm was changed, and the sheet|seat was obtained similarly to Example 1 except having changed. Table 1 shows the results of evaluating various properties using the obtained sheet.

PUM

| Property | Measurement | Unit |

|---|---|---|

| storage modulus | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com