Compound chlorhexidine acetate microemulsion disinfectant and its preparation method

A technology of chlorhexidine acetate and disinfectant, which is applied in the direction of disinfectant, botany equipment and method, biocide, etc., can solve the problems of low water solubility and the preparation cannot be used after being diluted, and achieves simple preparation method and prolonged disinfection Action time, effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] (1) Weigh 11.0 g of chlorhexidine acetate, 11.0 g of benzalkonium bromide, 18.5 g of polyoxyethylene ether hydrogenated castor oil (RH40), 12.5 g of ethanol, 3.4 g of ethyl acetate and 43.6 g of distilled water, and set aside;

[0029] (2) Mix the prescribed amount of chlorhexidine acetate and ethanol, then mix with RH40, then add ethyl acetate and mix, set aside;

[0030] (3) Dissolve the prescribed amount of benzalkonium bromide in distilled water as the water phase for later use;

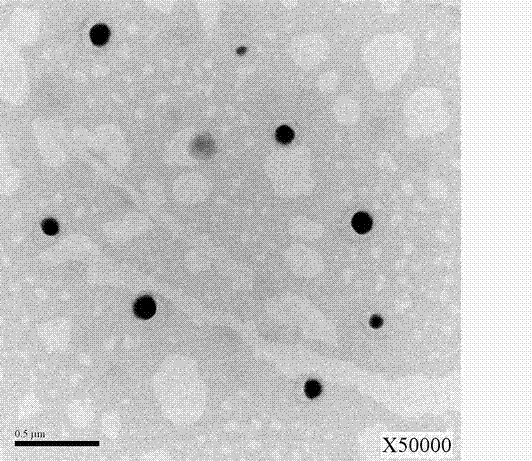

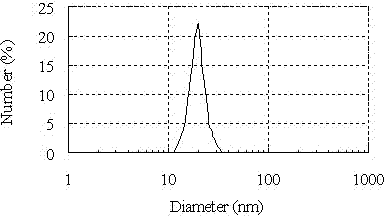

[0031] (4) At room temperature, slowly add the above water phase to the system while stirring continuously until a clear and transparent liquid is formed, that is, the compound chlorhexidine acetate microemulsion disinfection with a particle size of 10-100 nm and a clear and uniform appearance is prepared. agent.

Embodiment 2

[0033] (1) Weigh 0.02 g of chlorhexidine acetate, 0.02 g of benzalkonium bromide, 25 g of polyoxyethylene ether hydrogenated castor oil (RH40), 8.3 g of propylene glycol, 2.7 g of ethyl acetate and 64.0 g of distilled water, and set aside;

[0034] (2) Mix the prescribed amount of chlorhexidine acetate and propylene glycol, then mix with polyoxyethylene ether hydrogenated castor oil (RH40), then add ethyl acetate and mix, and set aside;

[0035] (3) Dissolve the prescribed amount of benzalkonium bromide in distilled water as the water phase for later use;

[0036] (4) At room temperature, slowly add the above water phase to the system while stirring continuously until a clear and transparent liquid is formed, that is, the compound chlorhexidine acetate microemulsion disinfection with a particle size of 10-100 nm and a clear and uniform appearance is prepared. agent.

Embodiment 3

[0038] (1) Weigh 6 g of chlorhexidine acetate, 3.6 g of benzalkonium bromide, 30.2 g of polyoxyethylene ether hydrogenated castor oil (RH40), 18.6 g of isopropanol, 5.0 g of ethyl acetate and 36.6 g of distilled water, and set aside ;

[0039] (2) Mix the prescribed amount of chlorhexidine acetate and isopropanol, then mix with polyoxyethylene ether hydrogenated castor oil (RH40), then add ethyl acetate and mix, set aside;

[0040] (3) Dissolve the prescribed amount of benzalkonium bromide in distilled water as the water phase for later use;

[0041] (4) At room temperature, slowly add the above water phase to the system while stirring continuously until a clear and transparent liquid is formed, that is, the compound chlorhexidine acetate microemulsion disinfection with a particle size of 10-100 nm and a clear and uniform appearance is prepared. agent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com