Formula for preparing novel functional non-dairy creamer by taking rice fructose syrup and rice protein peptide as wall materials to micro-gelatinize and cover and production method thereof

A technology of rice protein peptide and high fructose syrup, which is applied in the production/processing of edible oil/fat, edible oil/fat, and the preservation of edible oil/fat finished products, etc., to achieve improved safety, improved shelf life and improved tissue structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

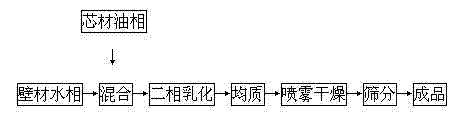

Method used

Image

Examples

Embodiment 1

[0053]Weigh 30kg of linoleic acid and place it in a hot and cold cylinder, keep it warm at 70°C and stir at 35r / min; then weigh 0.5kg of monoglyceride and 0.5kg of sodium stearyl lactylate and add it, continue to keep warm and stir completely, and then add 0.1kg of milk essence. Prepared as an oil phase liquid. Weigh 65kg of rice fructose syrup, 4kg of rice protein peptide, 2kg of sucrose ester, 1.5kg of dipotassium hydrogen phosphate, 0.3kg of sodium tripolyphosphate, 0.15kg of sodium hexametaphosphate, add 650kg of purified water and place in another hot and cold cylinder In the middle, keep stirring at 70°C at 35r / min until completely dissolved and uniform, and prepare an aqueous phase liquid. Transfer the oil phase liquid to the water phase liquid. In the two-phase mixed liquid, add a certain amount of pure water to adjust the total solid content of the two-phase mixed liquid to 37.5%, and the HLB value is 12.8. Then incubate and emulsify at 65-75°C at 35r / min for 20 min....

Embodiment 2

[0055] Weigh 35kg of corn germ oil and place it in a hot and cold cylinder, keep it warm at 75°C and stir at 35r / min; then weigh 0.6kg of monoglyceride and 0.5kg of sodium stearyl lactylate and add it, continue to keep warm and stir completely, then add 0.1kg of milk essence, Prepared as an oil phase liquid. Weigh 60kg rice fructose syrup, 3kg rice protein peptide, 2.4kg sucrose ester, 1.5kg dipotassium hydrogen phosphate, 0.3kg sodium tripolyphosphate, 0.15kg sodium hexametaphosphate, add 700kg of pure water and place in another cold and hot In the tank, stir at 35r / min under 70°C heat preservation until completely dissolved and uniform, and prepare an aqueous phase liquid. Transfer the oil phase liquid to the water phase liquid. In the two-phase mixed liquid, adjust the total solids mass fraction of the two-phase mixed liquid to 37.5% by adding a certain amount of pure water, and the HLB value is 12.8. Stir and emulsify at 75°C for 20 min with heat preservation at 35 r / min....

Embodiment 3

[0057] Weigh 40kg of camellia oil and place it in a hot and cold cylinder, keep it warm at 70°C and stir at 35r / min; then weigh 0.6kg of monoglyceride and 0.5kg of sodium stearyl lactylate and add it, continue to keep warm and stir evenly, then add 0.1kg of milk essence to prepare into oil phase liquid. Weigh 55kg rice fructose syrup, 4kg rice protein peptide, 2.4kg sucrose ester, 1.5kg dipotassium hydrogen phosphate, 0.3kg sodium tripolyphosphate, 0.15kg sodium hexametaphosphate, add 600kg of pure water and place in another cold and hot In the tank, stir at 35r / min under 70°C heat preservation until completely dissolved and uniform, and prepare an aqueous phase liquid. Transfer the oil phase liquid to the water phase liquid, in the two-phase mixed liquid, in the two-phase mixed liquid, adjust the total solid content of the two-phase mixed liquid to 37.5% by adding a certain amount of pure water, HLB value 12.8, and then keep warm at 65-75°C at 35r / min and stir and emulsify f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com