An Electric Field-Induced Fabrication Process of Two-Level Structures for Dry Adhesion

A technology of electric field induction and preparation technology, which is applied in the direction of technology for producing decorative surface effects, microstructure technology, microstructure devices, etc., can solve the problems of limited application, complicated process, poor material adaptability, etc., to improve processing efficiency, The process route is simple and the effect of reducing manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0019] An electric field-induced preparation process for a two-stage structure for dry adhesion, comprising the following steps:

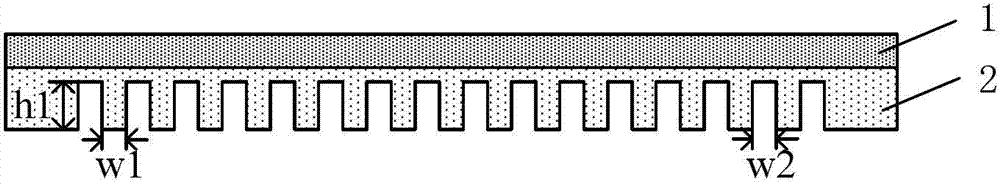

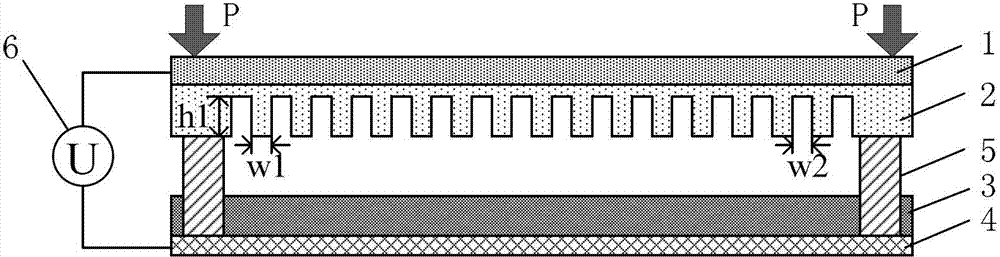

[0020] The first step is the preparation of the induced template: a pattern structure template of the second-level structure in the two-level structure is prepared on the surface of the Si wafer by photolithography, and a layer of micro-nano structure of PDMS or fluororesin 2, to obtain transparent inducible templates, such as figure 1 shown;

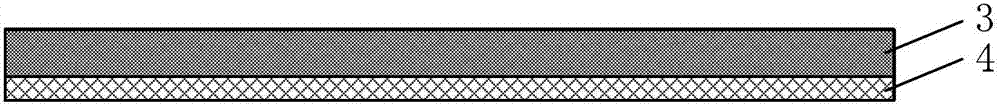

[0021] The second step, the selection and processing of the base material: use FTO or ITO glass 4 as the base material, and use a glue leveler to spin coat a layer of UV photocurable polymer material 3 on its surface. The thickness of the UV photocurable polymer material is micron scale, such as figure 2 as shown,

[0022] The third step, the electric field induces polymer rheological shaping:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com