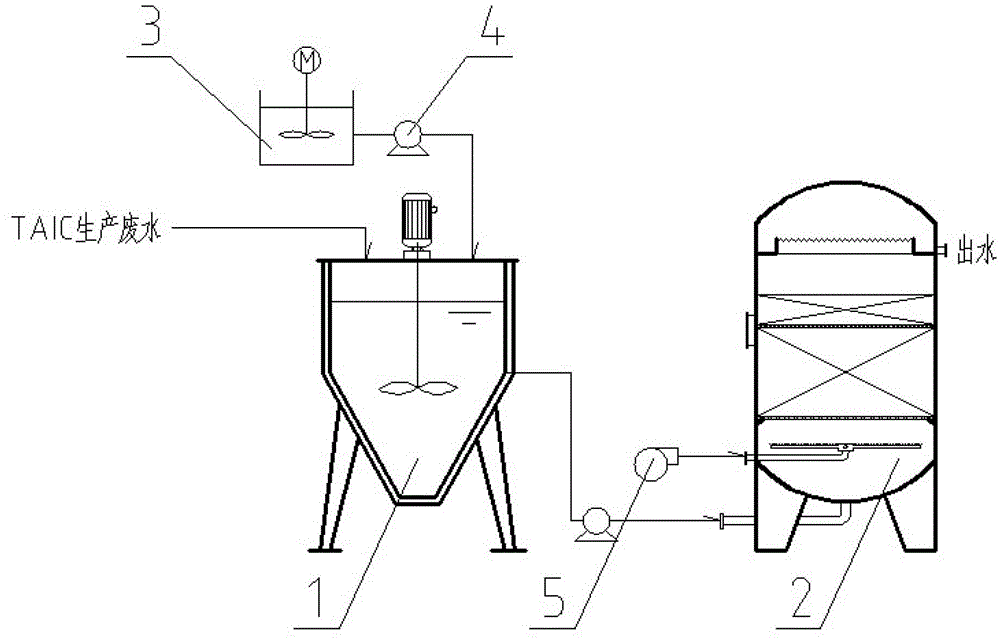

High-concentration TAIC (Triallyl Isocyanurate) production wastewater treating device and treating method

A technology for the production of wastewater and treatment devices, which is applied in the directions of water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., to achieve the effects of improving biodegradability, process economy and reasonableness, and good treatment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

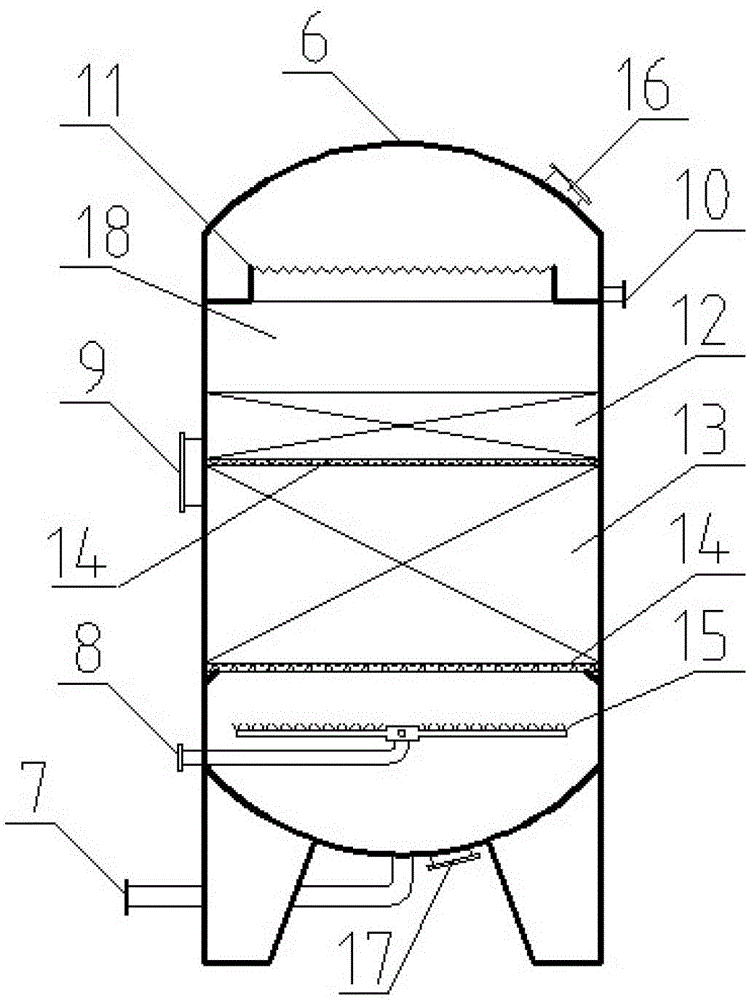

[0033] Wastewater quality: Jiangsu Suqian Huaxing (Chemical) Co., Ltd. TAIC production workshop wastewater, CODcr is 25440mg / L, TAIC content is 1500mg / L, pH is 3.

[0034] According to the above method, the pH of TAIC production wastewater is adjusted to be 5 in the pH adjustment tank; the mass ratio of iron filings and activated carbon in the iron-carbon filler is 2:1; the activated carbon is cylindrical granular, with a cross-sectional diameter of 2 mm and a length of 3-5mm, the length of iron filings is 3-5mm; the reaction time of wastewater in the iron-carbon micro-electrolysis reactor is 2h; the ratio of aeration to water is 6:1.

[0035] The CODcr removal rate of the treated TAIC wastewater effluent is more than 46%, and the TAIC removal rate is more than 48%, and the biodegradability is also greatly improved.

Embodiment 2

[0037] Same as in Example 1, except that the mass ratio of iron filings and activated carbon in the iron-carbon filler in Example 1 was changed to 1:1, the CODcr removal rate of the treated TAIC wastewater effluent was 38.2%, and the TAIC removal rate was 35.2%.

Embodiment 3

[0039] Same as in Example 1, except that the mass ratio of iron filings and activated carbon in the iron-carbon filler in Example 1 was changed to 3:1, the CODcr removal rate of the treated TAIC wastewater effluent was 35.3%, and the TAIC removal rate was 37.5%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com