Preparation method of fiber reinforced phosphate high-temperature-resistant composite material

A composite material and fiber reinforced technology, which is applied in the field of preparation of high temperature resistant composite materials, can solve the problems of many raw materials, high manufacturing cost, complicated preparation process, etc., and achieve the effect of low thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

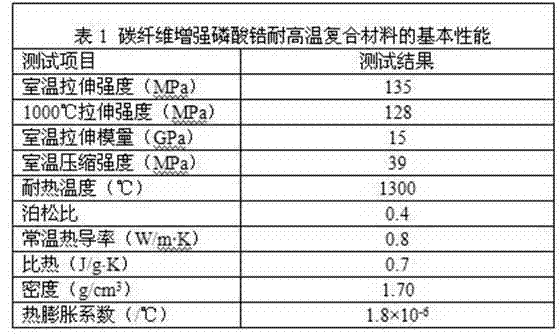

Embodiment 1

[0021] This embodiment includes the following steps:

[0022] (1) Preparation of carbon fiber prefabricated body: weave carbon fiber into plain weave with a fiber volume fraction of 50%;

[0023] (2) Carbon fiber prefabricated body pretreatment: arrange the plain weave obtained in step (1) in a vacuum furnace, heat up to 1300°C in an argon atmosphere, keep it warm for 2 hours, cool down to room temperature, and take it out for use;

[0024] (3) Coating, phosphoric acid impregnation and curing of the carbon fiber prefabricated body: first prepare the zirconium phosphate powder with an average particle size of 50 nanometers into a slurry (the concentration of zirconium phosphate in the slurry is 35wt%), and the slurry Brush on the carbon fiber cloth treated in step (2) (the thickness of the coating is 1-10 microns), stack the carbon fiber cloth after brushing, and then perform the puncture operation, heat to 550°C, and keep it warm for 3 hours; then vacuum (vacuum degree 150Pa)...

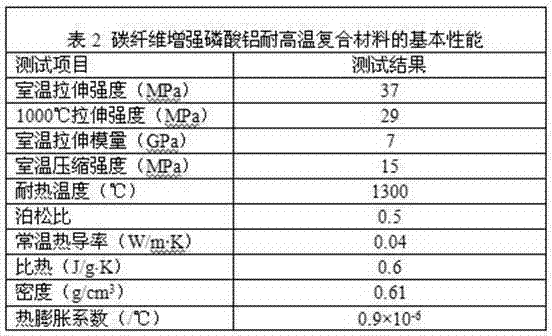

Embodiment 2

[0029] This embodiment includes the following steps:

[0030] (1) Preparation of carbon fiber prefabricated body: the carbon fiber is prepared into a prefabricated body with a volume fraction of 10% by needle punching and puncturing;

[0031] (2) Pretreatment of carbon fiber preform: place the preform obtained in step (1) in a vacuum furnace, raise the temperature to 1300°C in an argon atmosphere, keep it warm for 1 hour, cool down to room temperature, and take it out for use;

[0032] (3) Impregnate and solidify the carbon fiber preform: put the fiber preform treated in step (2) into the impregnation tank, vacuum inhale the aluminum dihydrogen phosphate solution with a concentration of 30wt%, until the fabric is submerged, and impregnate for 60 minutes , and then heated to 300°C at a heating rate of 3°C / min, and kept for 3 hours to crosslink and solidify the materials in the fabric;

[0033] (4) High-temperature treatment: put the fiber preform obtained in step (3) into a hi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com