Method for realizing increase production of butadiene

A technology of butadiene and butene, which is applied in the direction of chemical instruments and methods, hydrocarbons, hydrocarbons, etc., can solve the problems of different conversion rates and low yield of butadiene, achieve high conversion rates, eliminate waste Carbon, the effect of improving the yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

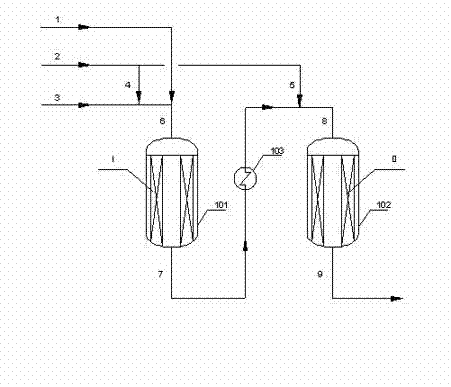

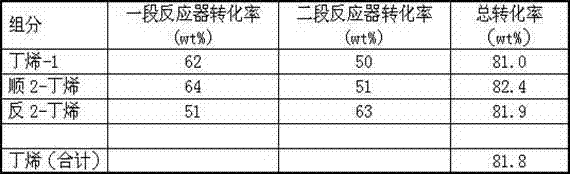

[0032]A 100,000 tons / year butene oxidative dehydrogenation to butadiene plant, the raw material butene composition is shown in Table 1, using figure 1 The process technology, the reactor has two sections, both of which are axial fixed bed reactors, the first section of the reactor is filled with iron-based oxide catalyst I, the main composition of iron, zinc, magnesium ratio (mole): Fe: Zn : Mg=10:3:6, the second stage reactor is filled with molybdenum-bismuth catalyst, the main composition is molybdenum, bismuth, iron, cobalt ratio (weight): Mo:Bi:Fe:Co=10:4:3: 6, the auxiliary agent is Sn, W, and the carrier is Al 2 o 3 , the feed rate is 20000kg / h, the total amount of air is 45600 kg / h, divided into 2 shares, the first stage of air is 32600 kg / h, the second stage of air is 13000kg / h, the amount of water vapor is 77000 kg / h, butene raw material and air, water After the steam is mixed according to the ratio of butene: oxygen: water (mol) of 1:0.60:12, it enters the first-st...

Embodiment 2

[0039] A 100,000 tons / year butene oxidative dehydrogenation to butadiene plant, the raw material butene composition is shown in Table 1, using figure 1 The process technology, the reactor has two sections, both of which are radial fixed bed reactors, the first section of the reactor is filled with iron-based oxide catalyst I, the main composition of iron, zinc, magnesium ratio (mole): Fe: Zn : Mg=10:3:6, the second stage reactor is filled with molybdenum-bismuth catalyst, the main composition is molybdenum, bismuth, iron, cobalt ratio (weight): Mo:Bi:Fe:Co=10:2:2.5: 5, the additive is Zn, the carrier is Al 2 o 3 , the feed rate is 20000kg / h, the total amount of air is 45600 kg / h, divided into 2 shares, the first stage of air is 32600 kg / h, the second stage of air is 13000kg / h, the amount of water vapor is 51400 kg / h, butene raw material and air, water After the steam is mixed according to the ratio of butene: oxygen: water (mol) of 1:0.60:8, it enters the first-stage reactor...

Embodiment 3

[0044] A 100,000 tons / year butene oxidative dehydrogenation to butadiene plant, the raw material butene composition is shown in Table 4, using figure 1 The process technology, the reactor has two sections, both of which are axial fixed bed reactors, the first section of the reactor is filled with iron-based oxide catalyst I, the main composition of iron, zinc, magnesium ratio (mole): Fe: Zn : Mg=10:2:3, the second stage reactor is filled with molybdenum-bismuth catalyst, the main composition is molybdenum, bismuth, iron, cobalt ratio (weight): Mo:Bi:Fe:Co=10:2:2.5: 6, the additive is Sn, the carrier is SiO 2 , the feed rate is 20000kg / h, the total amount of air is 45600 kg / h, divided into 2 shares, the first stage of air is 32600 kg / h, the second stage of air is 13000kg / h, the amount of water vapor is 77000 kg / h, butene raw material and air, water After the steam is mixed according to the ratio of butene: oxygen: water (mol) of 1:0.60:12, it enters the first-stage reactor at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com