Method for producing anhydrous citric acid crystal through inducing graining by continuous evaporation

An anhydrous citric acid and evaporation-induced technology, applied in the field of food chemical industry, can solve the problems of irregular crystal shape, uneven particle size and high production cost, and achieve the effects of uniform and complete size, low crystal moisture content and stable product quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

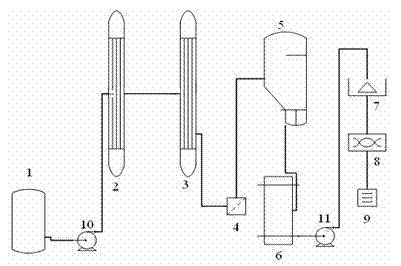

[0030] The concrete production method of present embodiment is as follows:

[0031] (1) Double-effect evaporation and concentration: the citric acid purified liquid from the citric acid production workshop is first passed into the refining storage tank 1, and after a short stay and buffer in it, it is pumped by the water pump 10 into one of the double-effect falling film evaporators. Efficient evaporator 2, evaporate and concentrate to a solution density of 1215kg / m under the conditions of vacuum degree -0.042kPa and temperature 78°C 3 , to obtain the citric acid first-effect evaporation concentrate; the concentrate then enters the second-effect evaporator 3, and evaporates and concentrates to a solution density of 1330kg / m under the conditions of a vacuum degree of -0.085kPa and a temperature of 56°C 3 , to obtain the citric acid two-effect evaporation concentrate.

[0032] (2) Filtration to remove impurities: the second-effect evaporation concentrate obtained in step (1) pa...

Embodiment 2

[0038] The concrete production method of present embodiment is as follows:

[0039] (1) Double-effect evaporation and concentration: the citric acid purified liquid from the citric acid production workshop is first passed into the refined storage tank 1, and after a short stay and buffer in it, it is pumped into the first-effect double-effect falling-film evaporator by the water pump 10 Evaporator 2, under the conditions of vacuum degree -0.045kPa and temperature 80°C, evaporate and concentrate to a solution density of 1220kg / m 3 , to obtain the citric acid first-effect evaporation concentrate; the concentrate then enters the second-effect evaporator 3, and evaporates and concentrates under the conditions of vacuum degree -0.088kPa and temperature 60°C until the solution density is 1332kg / m 3 , to obtain the citric acid two-effect evaporation concentrate.

[0040] (2) Filtration to remove impurities: the second-effect evaporation concentrate obtained in step (1) passes through ...

Embodiment 3

[0046] The concrete production method of present embodiment is as follows:

[0047] (1) Double-effect evaporation and concentration: the citric acid purified liquid from the citric acid production workshop is first passed into the refined storage tank 1, and after a short stay and buffer in it, it is pumped into the first-effect double-effect falling-film evaporator by the water pump 10 Evaporator 2, under the conditions of vacuum degree -0.005kPa and temperature 85°C, evaporate and concentrate to a solution density of 1250kg / m 3 , to obtain the citric acid first-effect evaporation concentrate; the concentrate then enters the second-effect evaporator 3, and evaporates and concentrates to a solution density of 1333kg / m under the conditions of a vacuum degree of -0.090kPa and a temperature of 65°C 3 , to obtain the citric acid two-effect evaporation concentrate.

[0048] (2) Filtration to remove impurities: the second-effect evaporation concentrate obtained in step (1) passes t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com