Method for preparing low-free curing agent with solid content of 75% by synthesis of 65/35 toluene diisocynate (TDI)

A technology of toluene diisocyanate and curing agent, which is applied in the field of preparation of low free TDI curing agent, and can solve the problems of too many raw materials and too long process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

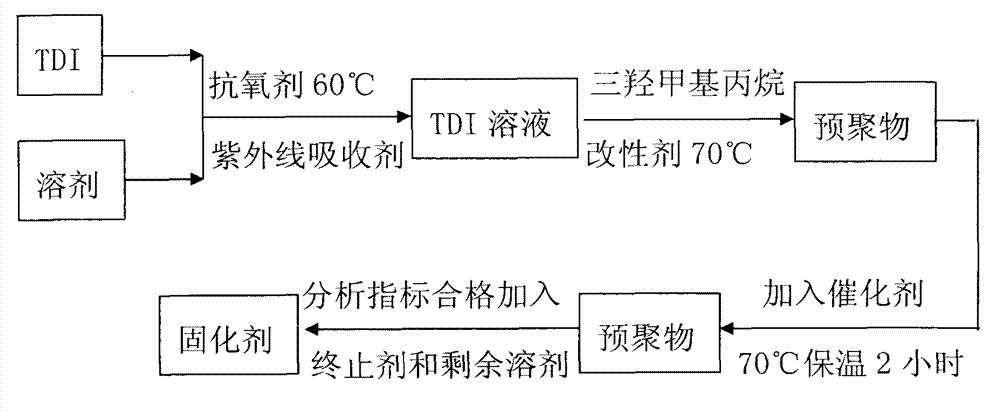

Method used

Image

Examples

Embodiment 1

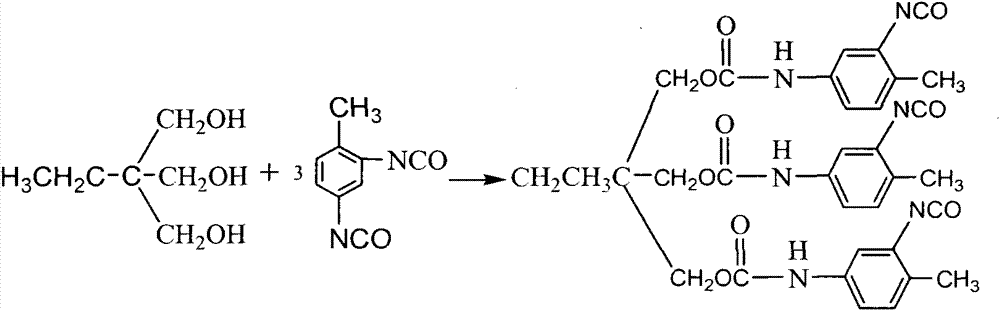

[0043] (1) First add 70kg of solvent butyl acetate, then add 400kg of 65 / 35 toluene diisocyanate (T-65) to mix, and heat to 50°C;

[0044] (2) Add 0.3kg of antioxidant 2,6-di-tert-butyl-p-cresol (BHT) and ultraviolet absorber 2-(2'-hydroxyl-3'5'-di-tert-butyl)-5-chloro - Benzotriazole 0.2kg, the above mixture is warmed up to 60°C;

[0045] (3) Divide 103kg of trimethylolpropane (TMP) into four parts, add 20kg of the first batch of TMP and mix and heat up to 62°C;

[0046] (4) After adding the second batch of TMP23kg and mixing, the temperature was raised to 65°C;

[0047] (5) Add the third batch of TMP27kg and mix and raise the temperature to 68°C;

[0048] (6) Add the fourth batch of TMP33kg and mix and raise the temperature to 70°C;

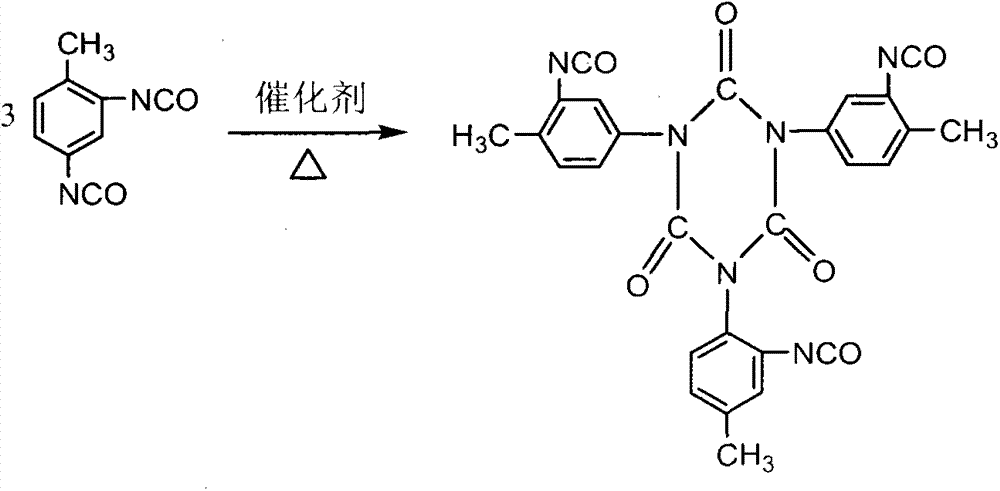

[0049] (7) After the temperature rise finishes, keep warm for half an hour, add catalyst 2,4,6-tris(dimethylaminomethylphenol) (DMP) 0.24kg, keep warm for 2-3 hours;

[0050] (8) When the viscosity and NCO% reach the requirements, the react...

Embodiment 2

[0053] (1) First add 80kg of solvent ethyl acetate, then add 400kg of 65 / 35 toluene diisocyanate (T-65) for mixing, and heat to 50°C;

[0054] (2) Add 0.3kg of antioxidant 2,6-di-tert-butyl-p-cresol (BHT) and ultraviolet absorber 2-(2'-hydroxyl-3'5'-di-tert-butyl)-5-chloro - Benzotriazole 0.2kg, the above mixture is warmed up to 60°C;

[0055] (3) Divide 103kg of trimethylolpropane (TMP) into four parts, first add the first batch of TMP20kg and mix and then heat up to 65°C;

[0056] (4) After adding the second batch of TMP23kg and mixing, the temperature was raised to 68°C;

[0057] (5) Add the third batch of TMP27kg and mix and then heat up to 70°C;

[0058] (6) Add the fourth batch of TMP33kg and mix and then heat up to 75°C;

[0059] (7) depending on the change in viscosity, add 50kg of solvent remaining ethyl acetate;

[0060] (8) After the temperature rise finishes, keep warm for half an hour, add catalyst 2,4,6-tris(dimethylaminomethylphenol) (DMP) 0.24kg, keep warm ...

Embodiment 3

[0063] Differences: 1. The chromaticity of the step-by-step feeding product is low, which is better than that of the traditional dripping process; 2. The viscosity of the feeding from less to more is low, which is conducive to the stable control of temperature, and the controllability of the reaction process is relatively high. Well, less by-products.

[0064] (1) Heat 1200kg of 65 / 35 toluene diisocyanate (T-65) to 50°C;

[0065] (2) Add antioxidant 2,6-di-tert-butyl-p-cresol (BHT) 0.9kg, ultraviolet absorber 2-(2'-hydroxyl-3'5'-di-tert-butyl)-5-chloro - Benzotriazole 0.6kg, the above-mentioned mixture is warmed up to 60 ℃;

[0066] (3) Divide 309kg of trimethylolpropane (TMP) into four parts, first add the first batch of TMP45kg and mix and then heat up to 65°C;

[0067] (4) Add the second batch of TMP55kg and mix;

[0068] (5) Add the third batch of TMP85kg and mix and then heat up to 68°C;

[0069] (6) Add the fourth batch of TMP124kg and mix and then heat up to 70°C; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com