The preparation and quality control method of high-purity dihedral chlorinated

A technology of chlorinated cinnamon and chlorinated cinnamon, applied in the direction of measuring devices, organic chemistry, instruments, etc., can solve the problem of not being able to meet the requirements of high-purity chlorinated chlorinated chemical reference materials, and the purity and quality control of chlorinated limpets Methods, high production costs and other issues, to achieve the effect of reasonable design, quality assurance, and short production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

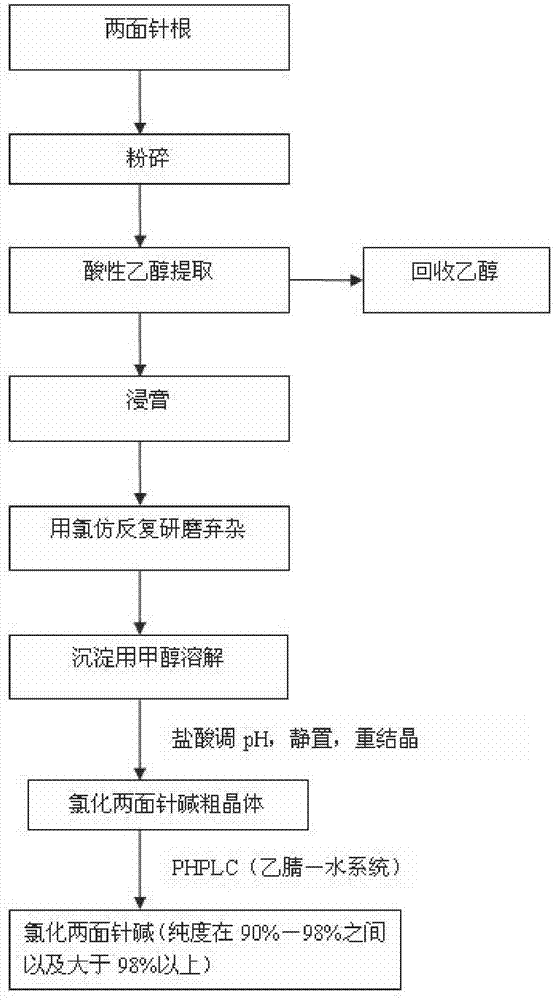

Method used

Image

Examples

Embodiment 1

[0043] (1) Grind the roots of Acupunctus lanceolata into coarse powder, add 80% ethanol with pH=3 to reflux and extract three times, add 10 times the amount of acidic ethanol for the first time, heat and reflux for 2 hours; add acidic ethanol 5 times for the second and third times Double the amount, heat and reflux for 2 hours respectively; combine the acid-alcohol extracts, recover ethanol, continue to concentrate to a thick paste, grind repeatedly with chloroform, dissolve the obtained precipitate with methanol, add hydrochloric acid to pH 2, and precipitate light yellow-green needles after standing Recrystallized with methanol, it is a crude crystal of dihedral chloride. The hydrochloric acid weight content of the acidic ethanol is 10-30% hydrochloric acid, the ethanol weight content is 40-80%, and the pH=3-4.

[0044] (2) The crude product of chlorinated acantholine was then dissolved in methanol, ultrasonicated for 30 minutes, heated to 90°C, filtered while it was hot, le...

Embodiment 2

[0046] Example 2: (1) Grind the roots of Acupunctus acutilis into coarse powder, add 70% ethanol with pH=3 to reflux and extract three times, add 12 times the amount of acidic ethanol for the first time, heat and reflux for 3 hours; the second and third times Add 6 times the amount of acidic ethanol, heat and reflux for 3 hours respectively; combine the acid-alcohol extracts, recover the ethanol, continue to concentrate to a thick paste, grind repeatedly with chloroform, dissolve the obtained precipitate with methanol, add hydrochloric acid until the pH is 2, and precipitate after standing Pale yellow-green needle-like crystals, recrystallized with methanol, is coarse crystals of dihedral chloride. The hydrochloric acid weight content of the acidic ethanol is 10-30% hydrochloric acid, the ethanol weight content is 40-80%, and the pH=3-4.

[0047] (2) The crude product of chlorinated acantholine was dissolved in methanol, ultrasonicated for 40 minutes, heated to 95°C, filtered ...

Embodiment 3

[0049] Example 3: (1) Grind the roots of Acupunctus edulis into coarse powder, add 50% ethanol with pH=4 to reflux and extract three times, add 15 times the amount of acidic ethanol for the first time, heat and reflux for 2 hours; the second and third times Add 5 times the amount of acidic ethanol, heat and reflux for 5 hours respectively; combine the acid-alcohol extracts, recover the ethanol, continue to concentrate to a thick paste, grind repeatedly with chloroform, dissolve the obtained precipitate with methanol, add hydrochloric acid until the pH is 3, and precipitate after standing Pale yellow-green needle-like crystals, recrystallized with methanol, is coarse crystals of dihedral chloride. The hydrochloric acid weight content of the acidic ethanol is 10-30% hydrochloric acid, the ethanol weight content is 40-80%, and the pH=3-4.

[0050] (2) The crude product of chlorinated acantholine was then dissolved in methanol, ultrasonicated for 60 minutes, heated to 80°C, filter...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com