Propeller antifouling method based on impulse current method

A technology of pulse current method and propeller, which is applied in the fields of pulse current method propeller antifouling and ship protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

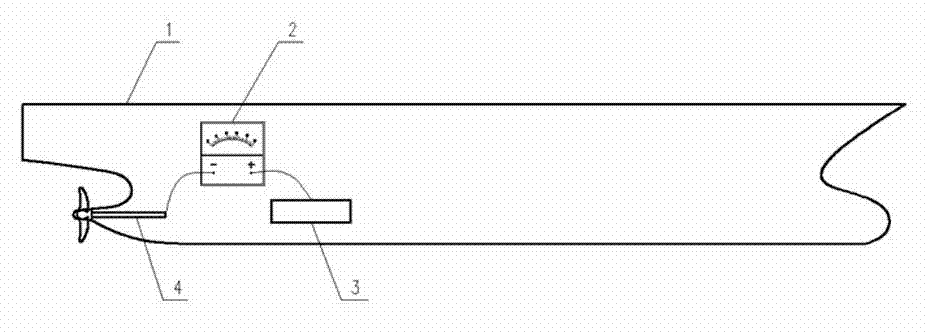

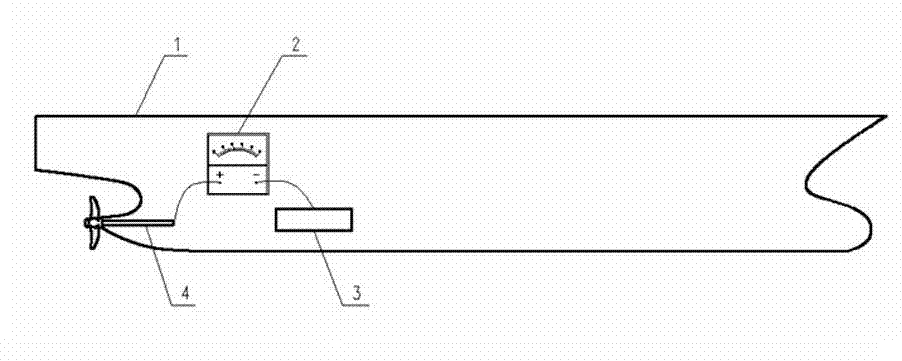

Image

Examples

Embodiment 1

[0018] Utilize the existing impressed current cathodic protection (ICCP) system at the stern of the ship, add an "anti-fouling mode" to the electric control cabinet of the impressed current protection system at the stern, and turn the impressed current system at the stern Switch to "Anti-Pollution Mode".

[0019] The working method of "anti-fouling mode" is: every 5 hours, the electric control cabinet is automatically reversed for 5 minutes (that is, the propeller is used as the anode, and the auxiliary anode is used as the cathode for constant current energization), and then it is switched to the normal power-on state (propeller is the cathode, and the auxiliary anode is the anode), and so on, the experiment period is 6 months.

[0020] The results showed that the ship's propeller did not have marine growth phenomenon, and there was no obvious corrosion phenomenon.

Embodiment 2

[0022] Utilize the existing impressed current cathodic protection (ICCP) system at the stern of the ship, add an "anti-fouling mode" to the electric control cabinet of the impressed current protection system at the stern, and turn the impressed current system at the stern Switch to "Anti-Pollution Mode".

[0023] The working method of "anti-fouling mode" is: every 6 hours, the electric control cabinet is automatically energized in reverse for 10 minutes (that is, the propeller is used as the anode, and the auxiliary anode is used as the cathode for constant current energization), and then switched to the normal power-on state (propeller is the cathode, and the auxiliary anode is the anode), and so on, the experiment period is 6 months.

[0024] The results showed that the ship's propeller did not have marine growth phenomenon, and there was no obvious corrosion phenomenon.

Embodiment 3

[0026] Utilize the existing impressed current cathodic protection (ICCP) system at the stern of the ship, add an "anti-fouling mode" to the electric control cabinet of the impressed current protection system at the stern, and turn the impressed current system at the stern Switch to "Anti-Pollution Mode".

[0027] The working method of "anti-fouling mode" is: every 7 hours, the electric control cabinet is automatically reversed for 5 minutes (that is, the propeller is used as the anode, and the auxiliary anode is used as the cathode for constant current energization), and then it is switched to the normal power-on state (propeller is the cathode, and the auxiliary anode is the anode), and so on, the experiment period is 6 months.

[0028] The results showed that the ship's propeller did not have marine growth phenomenon, and there was no obvious corrosion phenomenon.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com