Antireflaction hard coating film and method of preparing the same

An anti-reflection and hard coating technology, applied in anti-reflection coatings, coatings, sputtering coatings, etc., can solve problems such as difficulty in achieving high hardness, curling, and insufficient flexibility, and achieve increased hardness and curl suppression Characteristics, effects of excellent hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

[0199] Combine 2-(3,4-epoxycyclohexyl) ethyl trimethoxysilane (ECTMS, TCI) and water (H 2 O, Sigma-Aldrich (Sigma-Aldrich) was mixed at a ratio of 24.64g:2.70g (0.1mol:0.15mol) and added to a 250mL 2-neck flask. Then, 0.1 mL of tetramethylammonium hydroxide (Sigma-Aldrich) catalyst and 100 mL of tetrahydrofuran (Sigma-Aldrich) were added to the mixture, and the mixture was stirred at 25°C for 36 hours. After that, the layers are separated, the product layer is extracted with dichloromethane (Sigma-Aldrich), and the water in the extract is removed with magnesium sulfate (Sigma-Aldrich), and the solvent is vacuum dried to obtain epoxy silicon Oxyane resin. As a result of gel permeation chromatography (Gel Permeation Chromatography, GPC) measurement, the weight average molecular weight of the epoxy siloxane resin was 2500.

Embodiment 1

[0201] 30 parts by weight of the epoxy siloxane resin prepared in Preparation Example 1 and 15 parts by weight of (3',4'-epoxycyclohexyl) methyl 3,4-epoxycyclohexane carboxylate (Daicel Company, Celloxide 2021P), 1 part by weight of 4-acetoxyphenyldimethylsulfonium hexafluoroantimonate (Sanshin Company, SI-60), 1 part by weight of (4 -Methylphenyl)[4-(2-methylpropyl)phenyl] iodonium hexafluorophosphate, 0.3 parts by weight of silicone polymer (BYK Chemical Company, BYK3560, leveling agent) and 52.7 parts by weight Parts of methyl ethyl ketone (Sigma-Aldrich) were mixed to prepare a composition for forming a hard coat layer.

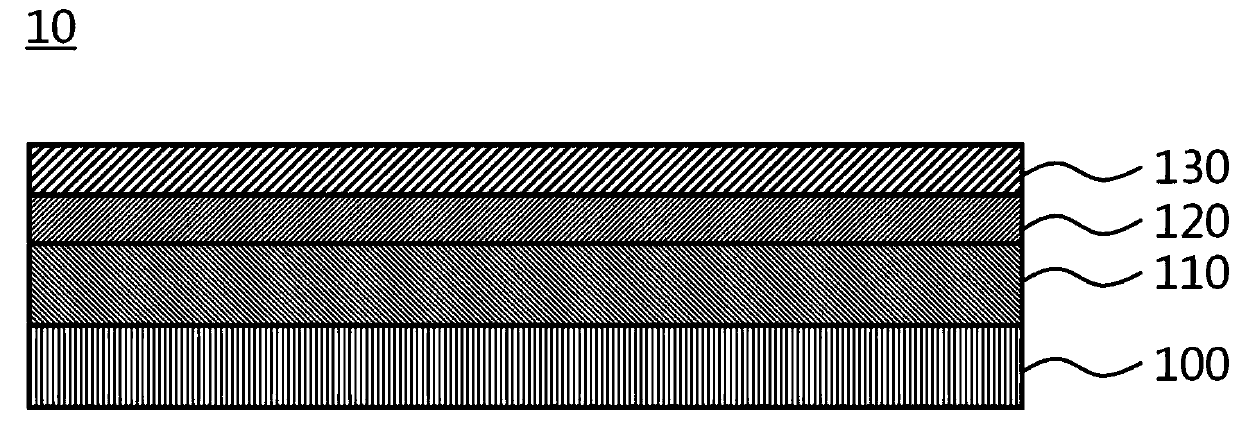

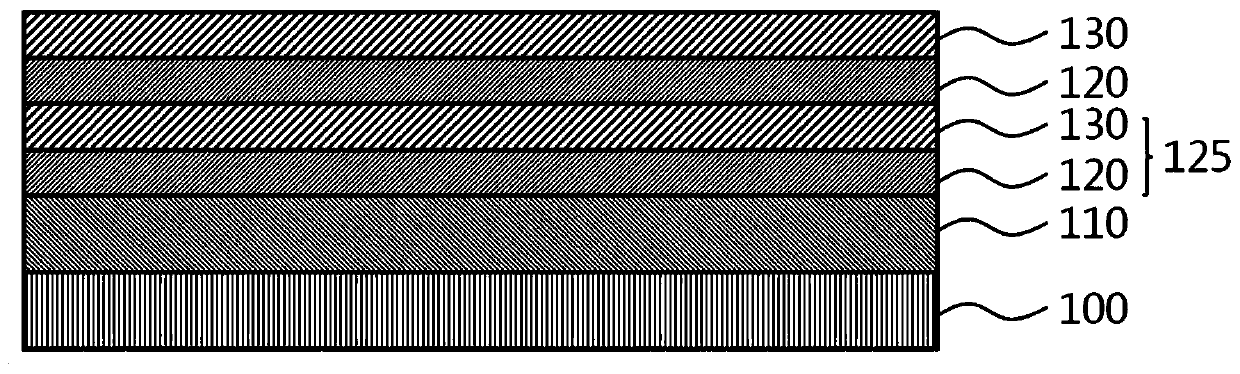

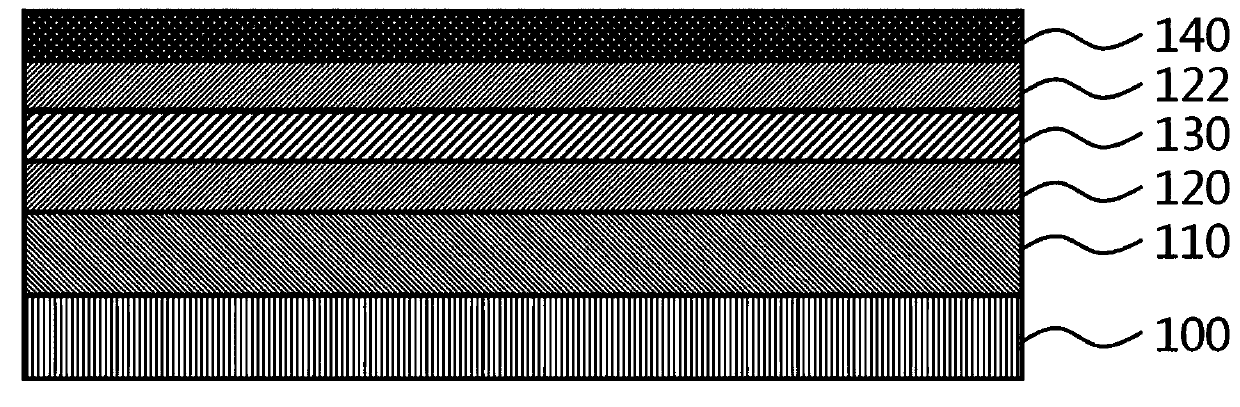

[0202] The composition for forming a hard coat layer was coated on a colorless polyimide (cPI) film with a thickness of 80 μm by the Meyer rod method, and left to stand at a temperature of 60° C. for 5 minutes. Using high-pressure metal lamp at 1J / cm 2 UV was irradiated, and then cured at a temperature of 120° C. for 15 minutes to form a hard coat with a th...

Embodiment 2

[0207] In Example 1, in addition to using sputtering ZrO 2 Except that the high refractive index layer with a refractive index of 2.2 was formed instead of the high refractive index layer, an anti-reflection hard coating film was prepared by the same method as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| water contact angle | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com