Mixed decene oligomerization catalyst

A catalyst and decene technology, applied in physical/chemical process catalysts, organic compound/hydride/coordination complex catalysts, organic chemistry, etc., can solve low conversion rate, low 1-decene content, no separation technology To achieve the effect of improving the utilization rate of raw materials, reducing input costs and increasing economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

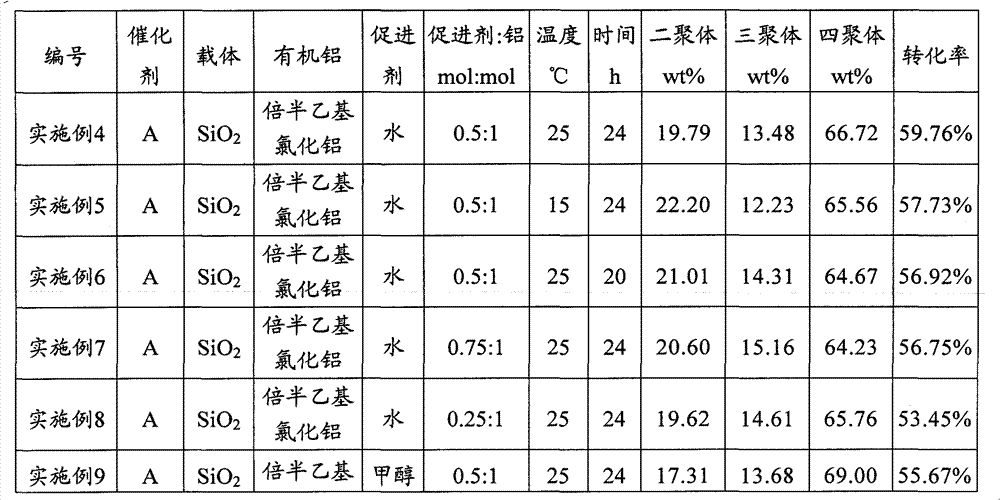

Examples

Embodiment 1

[0023] Preparation of Catalyst A:

[0024] Weigh 10g of silicon dioxide and sinter at 700°C for 15 hours, then cool down to 200°C, and put it in a vacuum drying oven for later use. Under nitrogen protection, add above-mentioned processed silicon dioxide and 50ml n-hexane into the polymerization bottle, add 4g of sesquiethylaluminum chloride with a mass concentration of 25% in the polymerization bottle with a syringe, stir at room temperature for 1 hour, and use After washing with n-hexane, the obtained solid was vacuum-dried for 10 hours to obtain supported catalyst A.

Embodiment 2

[0026] Preparation of Catalyst B:

[0027] The operation method is the same as that of Example 1, except that the silica carrier is replaced by aluminum oxide to obtain supported catalyst B.

Embodiment 3

[0029] Preparation of Catalyst C

[0030] The operation method is the same as in Example 1, except that the sesquiethylaluminum chloride is replaced by 4 g of ethylaluminum dichloride to obtain supported catalyst C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com