Method for forming coal particles through hydrophobic agglomeration

A technology of agglomeration and coal particles, applied in the field of preparation of ultra-pure coal by hydrophobic agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0019] A method for preparing hydrophobic agglomerated coal particles, comprising:

[0020] (1) Grinding the flotation concentrate, the particle size distribution after the flotation concentrate grinding and dissociation is: d 10 =3μm±2μm;

[0021] (2) The coal sample after grinding and dissociation and the flocculant are dispersed in water to obtain the coal sample after the agglomeration, the flocculant includes emulsified kerosene, and the particle size distribution of the coal degree of the agglomeration is: d 10 =35 μm±2 μm.

[0022] The emulsified kerosene includes kerosene and water. Preferably, the mass ratio of water and kerosene in the emulsified kerosene is 3.5:1˜5:1.

[0023] In step (1), the preparation method of the flotation concentrate includes: dispersing the flotation clean coal in water, adding a flotation agent to carry out flotation scraping.

[0024] The flotation scraping time is controlled at 1.5min to 3min.

[0025] After the flotation clean coal ...

Embodiment 1

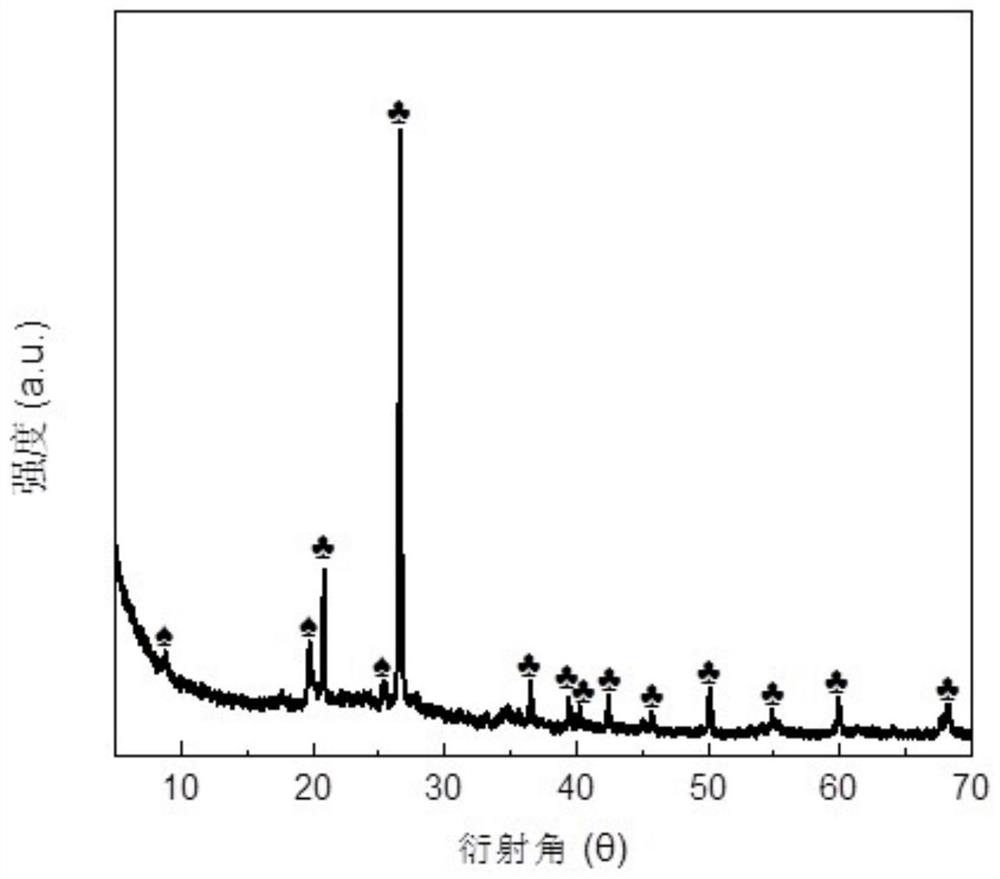

[0062] The X-ray diffraction pattern of raw flotation clean coal shows diffraction peaks appearing at 8.75°, 17.58°, 19.76°, 20.86°, 26.64°, 36.54° and 50.14°, as shown in the attached figure 1 . Particle size distribution of gangue minerals d 50 = 11.48 μm, d 90 = 40.22 μm.

[0063] (1) Disperse the flotation clean coal in the flotation tank, the pulp concentration is 10%, add an appropriate amount of emulsified kerosene 0.5%, sodium lignosulfonate 500g / t, methyl isobutyl carbinol 25g / t in the pulp, Flotation scraping, to separate some coal particles and gangue particles in the flotation clean coal to obtain flotation concentrate, the ash content of which is 3.94%.

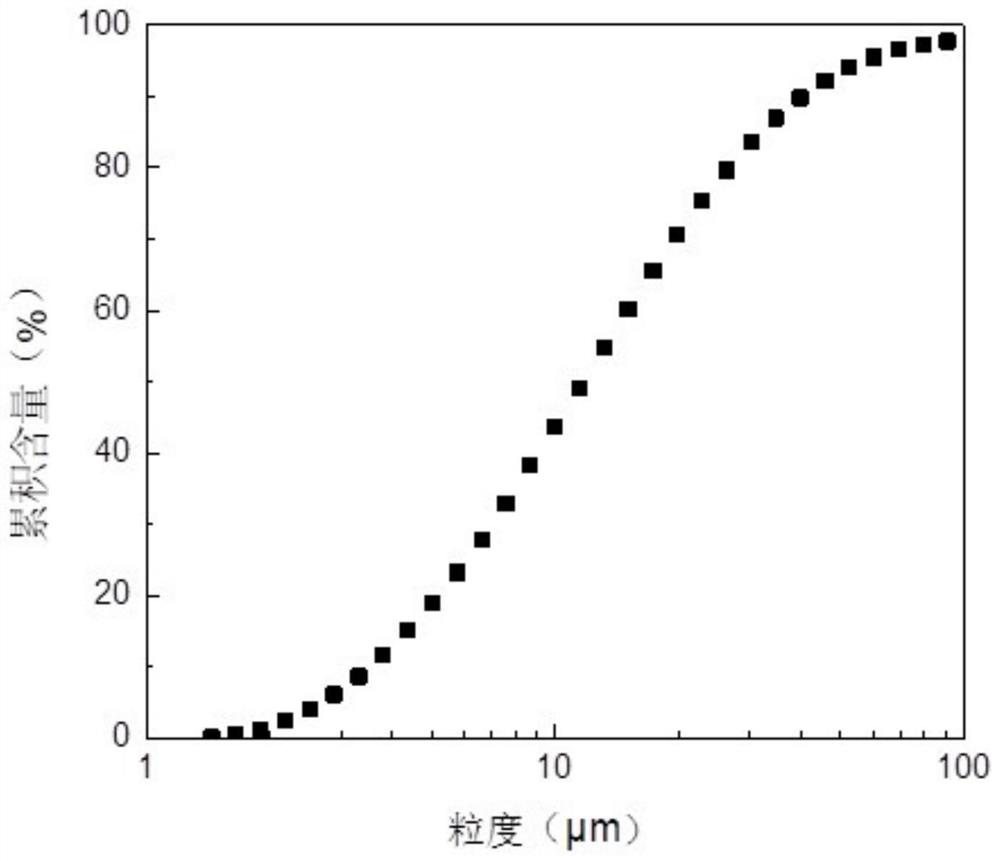

[0064] (2) The flotation concentrate obtained in step 1 is ground and dissociated in a planetary ball mill, and the particle size distribution of the coal sample ash after grinding is d 10 = 3.124 μm, d 50 = 13.253 μm, d 90 = 62.341 μm.

[0065] (3) Disperse the coal sample after grinding and dissociation ...

Embodiment 2

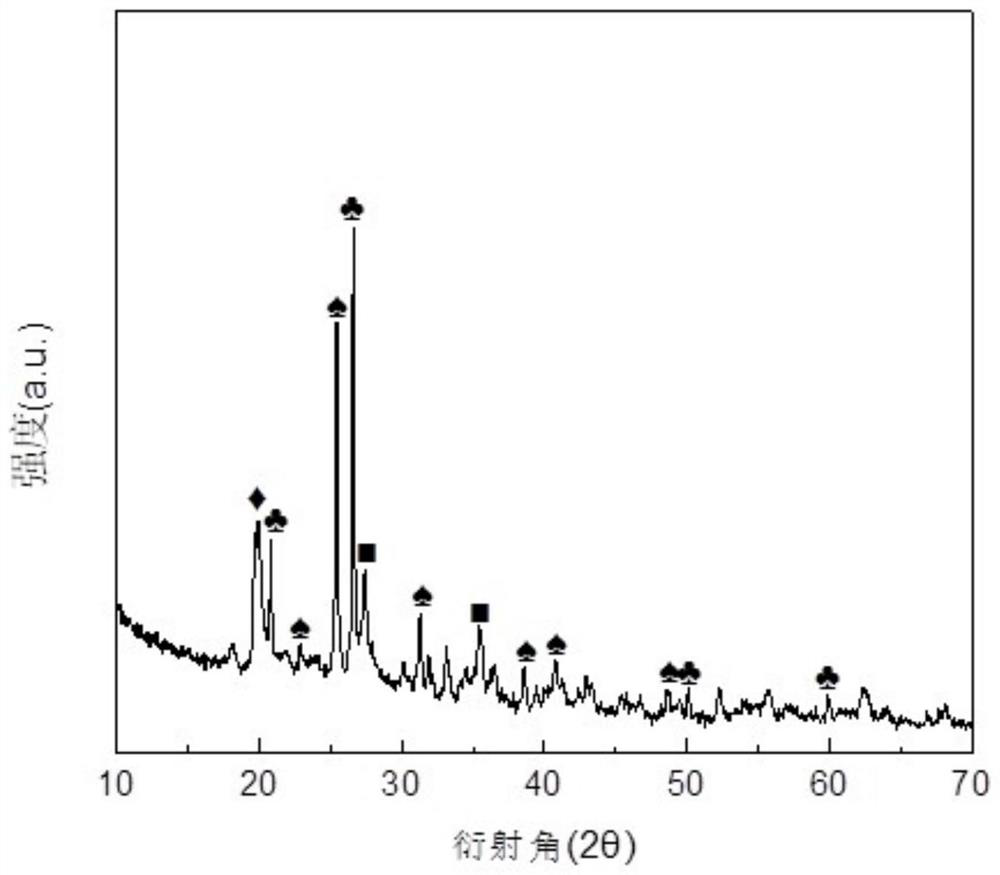

[0069] The X-ray diffraction patterns of raw flotation clean coal are shown at 8.75°, 17.58°, 19.76°, 20.86°, 22.93°, 25.43°, 26.64°, 27.35°, 31.37°, 35.54°, 36.54°, 38.65°, 40.82° ° and 50.14 ° of diffraction peaks, as shown in the attached image 3 . Particle size distribution of gangue minerals d 50 = 40.27 μm, d 90 = 241.91 μm.

[0070] (1) Disperse the flotation clean coal in the flotation tank, the pulp concentration is 10%, add an appropriate amount of emulsified kerosene 0.5%, sodium lignosulfonate 500g / t, methyl isobutyl carbinol 25g / t in the pulp, Flotation scraping, to separate part of the coal particles and gangue particles in the flotation clean coal to obtain flotation concentrate, the ash content of which is 5.50%.

[0071] (2) Step 1 obtains the flotation concentrate and carries out grinding and dissociation, and the particle size distribution of the coal sample ash after grinding is attached Figure 5 .

[0072] (3) Disperse the coal sample after grindin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| D10 | aaaaa | aaaaa |

| D50 | aaaaa | aaaaa |

| D90 | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com