Preparation method of vulcanization type catalyst

A catalyst and sulfurized type technology, applied in the field of preparation of sulfurized hydrogenation catalysts, can solve problems such as affecting the air tightness of the device, and achieve the effects of increasing sulfurization degree, avoiding overheating and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] 1. Preparation of catalyst carrier: Prepare the catalyst carrier by conventional methods, and select the carrier type according to the number of acid sites required by the catalyst, such as silica-alumina, silica with additives, alumina or molecular sieve with additives, etc. The carrier powder is mixed with binder, pore-enlarging agent and extrusion aid, extruded on an extruder, dried and calcined to make a catalyst carrier. The catalyst carrier preparation method is well known to those skilled in the art.

[0023] 2. Preparation of sulfurized catalyst

[0024] a) Prepare solutions containing Mo or W sulfide precursors and solutions containing Ni or Co inorganic salts respectively, and impregnate the carrier in two steps. After the first step impregnates the catalyst carrier with a solution containing Mo or W sulfide precursors, Dry at 20°C to 200°C for 1 to 10 hours. In the second step, impregnate the dried catalyst carrier with an impregnating solution containing Ni...

Embodiment 1

[0027] Embodiment 1 Preparation of sulfurized catalyst A

[0028]Weigh pseudo-boehmite (produced by Shandong Alumina Plant, 73% by weight on a dry basis) 900g, 19g of scallop powder, 32g of citric acid, 48ml of nitric acid (30% by weight), silica gel (containing two by weight) Silica 30%) 159ml, deionized water 250ml, mixed evenly, extruded on extruder into 1.2mm clover strips, dried and calcined at 600°C for 3 hours to obtain the required catalyst carrier 1.

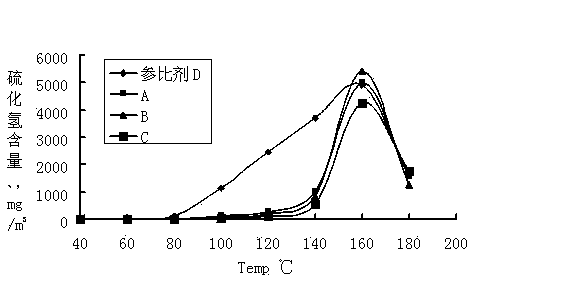

[0029] Take a solution containing ammonium thiomolybdate and nickel nitrate (containing molybdenum oxide 30g / 100ml, nickel oxide 24g / 100ml) impregnated carrier 1 and then dried at 180°C for 3 hours, took straight-run diesel oil and sprayed the obtained catalyst precursor, at 200 ℃ for 3 hours, so that the final catalyst contains 5wt% of straight-run diesel oil to obtain catalyst A, whose hydrogen sulfide curve is shown in figure 1 .

Embodiment 2

[0030] Embodiment 2 Preparation of sulfurized catalyst B

[0031] Take ammonium thiomolybdate solution (containing molybdenum oxide 30 g / 100ml) to impregnate carrier 1 and dry at 180°C, take nickel nitrate solution (containing nickel oxide 10g / 100ml) to spray the obtained catalyst precursor, and dry at 180°C For 3 hours, get the dried sample obtained before spraying and immersing the ethanol solution containing hexadecane (wherein containing 50wt% hexadecane), and treat it for 3 hours at 180°C, so that the final catalyst contains 5wt% hexadecane, to obtain catalyst B. Its hydrogen sulfide curve is shown in figure 1 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com