Preparation method of flaky nano-hydroxyapatite

A nano-hydroxyapatite and flaky technology, applied in nanotechnology, chemical instruments and methods, phosphorus compounds, etc., can solve the problems of rare reports and achieve safe and non-toxic reagents, simple process, and biocompatibility Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

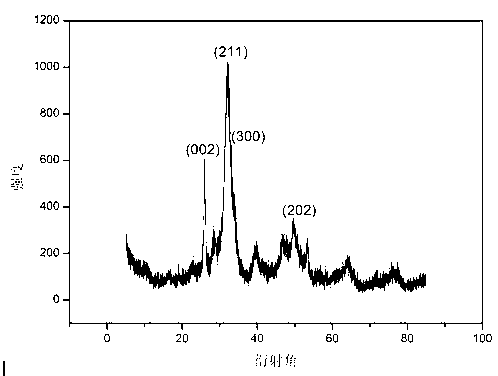

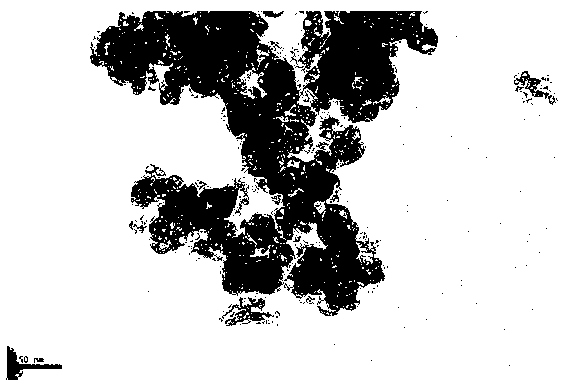

Image

Examples

Embodiment 1

[0019] Dissolve 0.1g of chondroitin sulfate (CS) in ultrapure water and stir at 4°C to make a 1.25% (w / v) CS solution; get 420ml of 0.1mol / L CaCl2 solution and add it into the prepared mixed solution, mix 20 minutes with slow heating to 40°C. Then slowly add NaH2PO4 solution (252ml, 0.1mol / L) and adjust the pH value with 0.1mol / L NaOH. When the pH value is 7, a white suspension appears and lasts for 24 hours. Centrifuge the saturated solution with a centrifuge (5000rpm, 5min), remove the supernatant, wash repeatedly with deionized water to remove salt ions, and dry at low temperature to obtain flaky nano-hydroxyapatite.

Embodiment 2

[0021] Dissolve 0.1g of hyaluronic acid (HA) in ultrapure water and stir at 4°C to make a 1.25% (w / v) HA solution; take 420ml of the CaCl2 solution with a concentration of 0.1mol / L and add it to the prepared mixed solution, mix 20 minutes with slow heating to 40°C. Then slowly add NaH2PO4 solution (252ml, 0.1mol / L) and adjust the pH value with 0.1mol / L NaOH. When the pH value is 7, a white suspension appears and lasts for 24 hours. Centrifuge the saturated solution with a centrifuge (5000rpm, 5min), remove the supernatant, wash repeatedly with deionized water to remove salt ions, and dry at low temperature to obtain flaky nano-hydroxyapatite.

Embodiment 3

[0023] Dissolve 0.1g of heparan sulfate (HS) in ultrapure water and stir at 4°C to make a 1.25% (w / v) HS solution; take 420ml of the CaCl2 solution with a concentration of 0.1mol / L and add it to the prepared mixed solution, mix 20 minutes with slow heating to 40°C. Then slowly add NaH2PO4 solution (252ml, 0.1mol / L) and adjust the pH value with 0.1mol / L NaOH. When the pH value is 7, a white suspension appears and lasts for 24 hours. Centrifuge the saturated solution with a centrifuge (5000rpm, 5min), remove the supernatant, wash repeatedly with deionized water to remove salt ions, and dry at low temperature to obtain flaky nano-hydroxyapatite.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com