Bimetallic catalyst for synthetizing vertical structure regular makrolon

A bimetallic catalyst, polycarbonate technology, applied in the field of catalysts, can solve the problems of long reaction time, high pressure, difficult separation of products and catalysts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

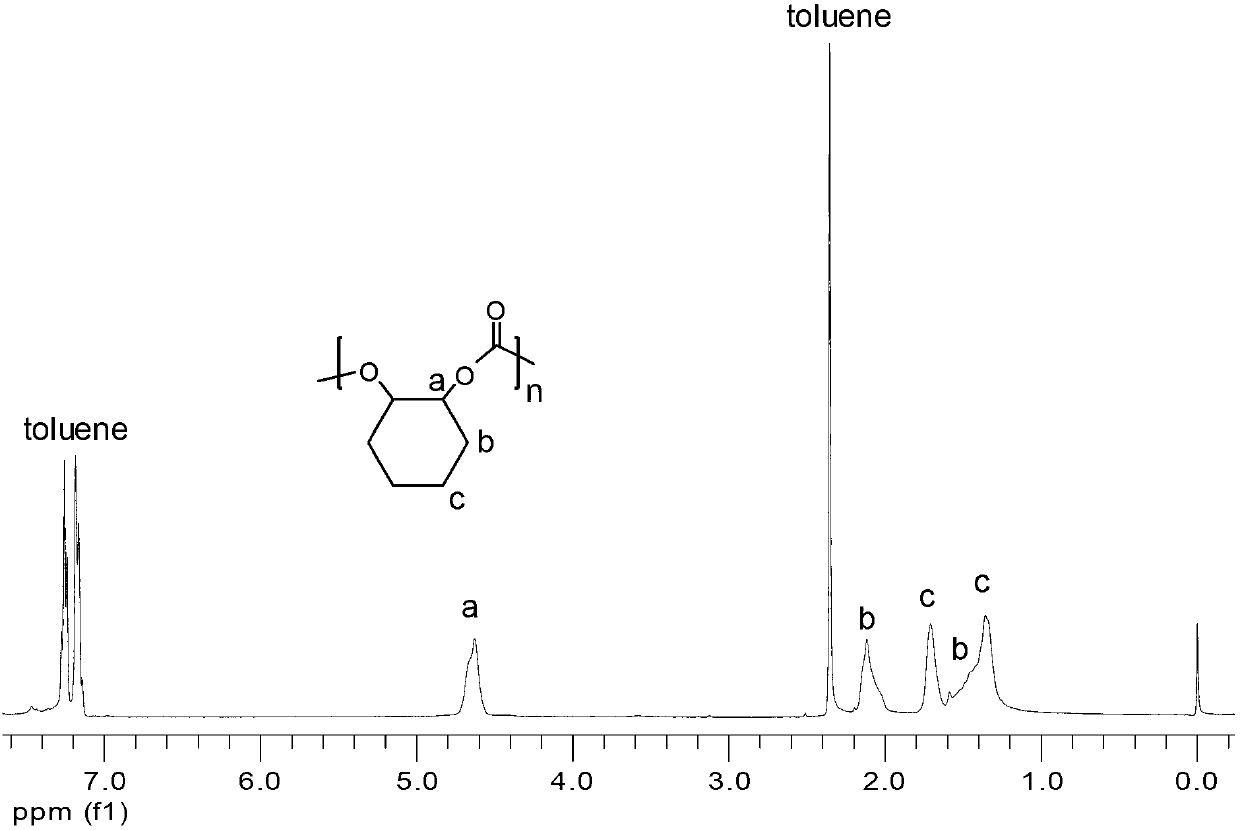

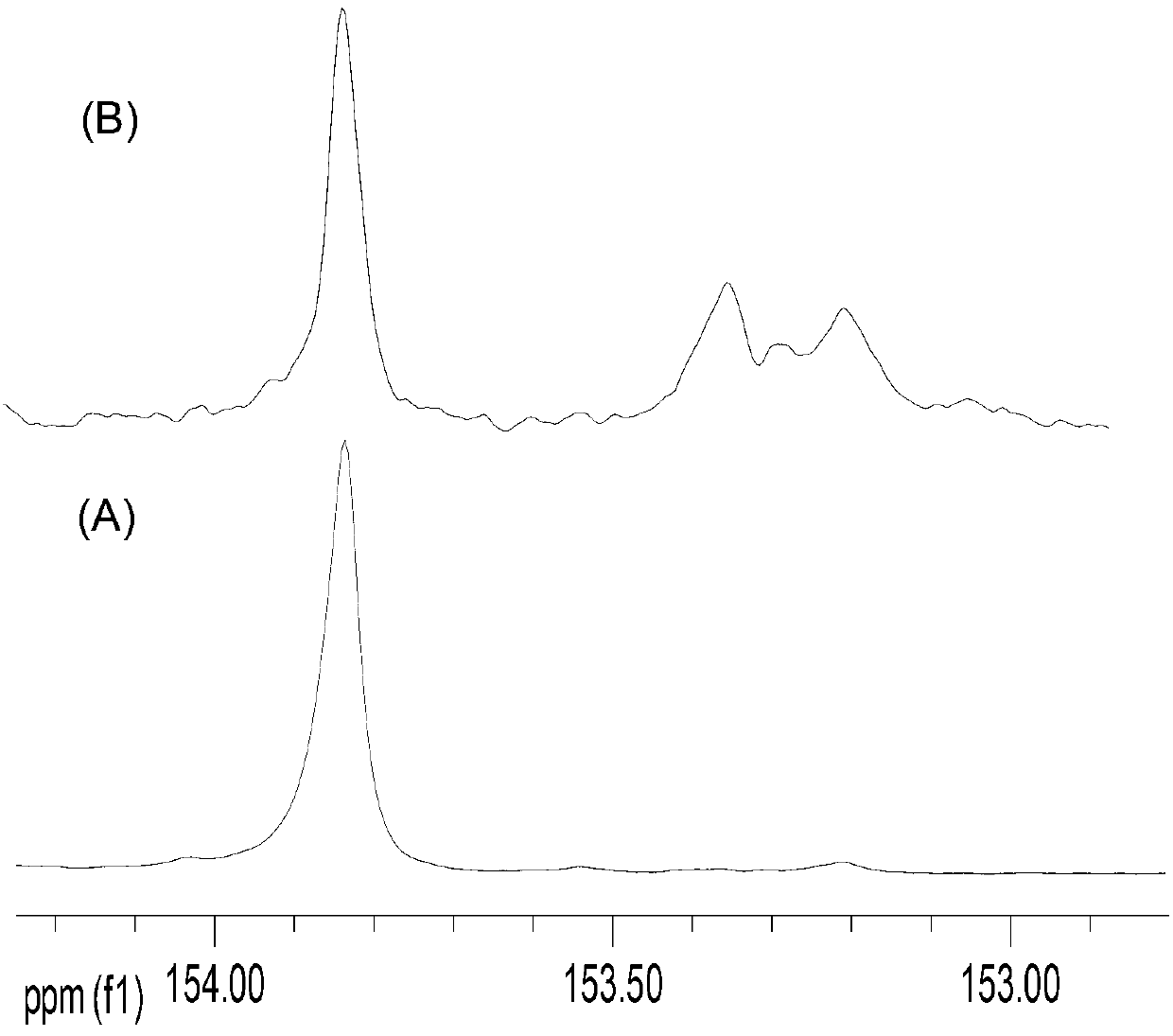

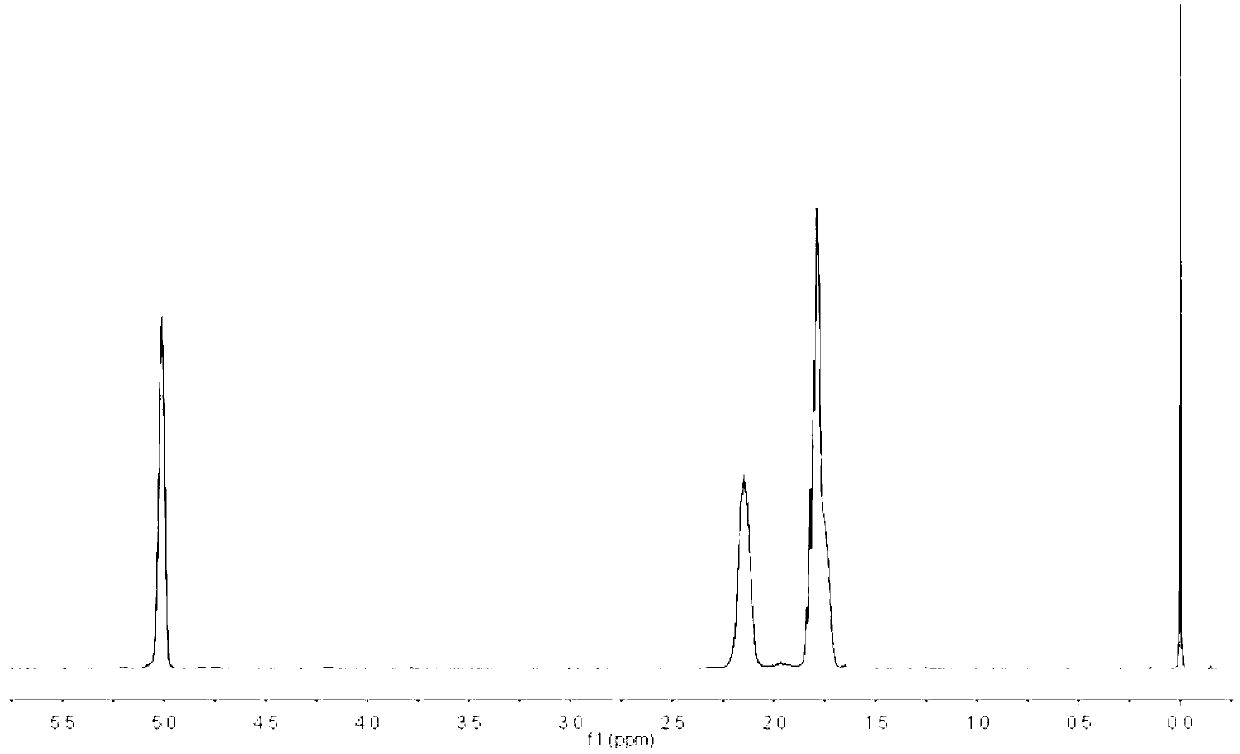

[0039] Specific embodiments of the present invention are described in detail below in combination with technical solutions (Table 1-3). Among them, Table 1 relates to the alternating copolymerization reaction of trivalent metal complexes catalyzed carbon dioxide and epoxycyclohexane; Table 2 relates to the alternating copolymerization reaction of trivalent metal complexes catalyzed carbon dioxide and epoxycyclopentane; Table 3 relates to divalent metal complexes The complex catalyzes the alternating copolymerization reaction of carbon dioxide and alkylene oxide.

[0040] In a 100mL stainless steel autoclave, add in the following order at ambient temperature: a certain amount of main catalyst (any metal complex described in the first article of the claim), cocatalyst R 1 R 2 3 YX 1 (if necessary), then pump 20mL alkylene oxide into the sealed autoclave respectively, feed carbon dioxide gas, and rapidly rise to the set temperature, and keep the carbon dioxide pressure in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com