Bamboo-plastic composite material and preparation method and application thereof

A composite material and bamboo-plastic technology, applied in covering/lining, construction, building structure, etc., can solve the problems of reduced processing fluidity and mechanical properties, affecting the composite performance of bamboo-plastic composite materials, and inability to produce products with complex shapes. , to achieve the effect of good dimensional stability, good product stability and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

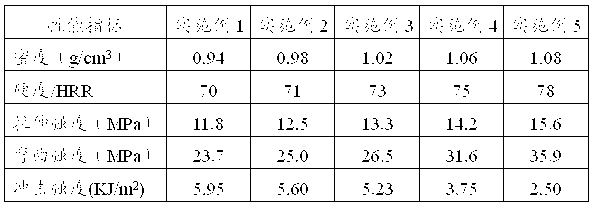

Examples

Embodiment 1

[0038] Weigh the raw materials (parts by weight) according to the following weight:

[0039] 20 parts of bamboo fiber,

[0040] 70 parts of polyethylene,

[0041] Coupling agent KH550 0.5 parts,

[0042] Compatibility agent PE-g-MAH 1.5 parts,

[0043] 0.5 part of light calcium carbonate as nucleating agent,

[0044] Lubricant polyethylene wax 0.5 part,

[0045] 2 parts of mixing aids.

[0046] The mixing auxiliary agent is specifically 0.8 parts of zinc oxide, 0.4 parts of antioxidant 1010, 0.4 parts of auxiliary antioxidant, and 0.4 part of acrylate copolymer.

[0047] The bamboo fiber is sieved through a 40-100 mesh screen and dried at 90°C for 5 hours; then the above bamboo fiber and polyethylene are heated and mixed in a high-speed mixer, and the coupling agent, compatibilizer, Lubricant, nucleating agent and mixing aids are mixed uniformly, and the mixing temperature is controlled at 100°C and the rotating speed is 100r / min; after the mixing is uniform, it is cooled to 20°C to obtain...

Embodiment 2

[0049] Weigh the raw materials (parts by weight) according to the following weight:

[0050] 30 parts of bamboo fiber,

[0051] 60 parts of polypropylene,

[0052] 2 parts of coupling agent KH570,

[0053] Compatibility agent PP-g-MAH 5 parts,

[0054] 2 parts of nucleating agent talcum powder,

[0055] Lubricant silicone oil 2 parts,

[0056] 3 parts of mixing aids.

[0057] Among them, 1.2 parts of zinc oxide, 0.6 parts of antioxidant 1010, 0.6 parts of auxiliary antioxidant 168, and 0.6 parts of acrylate copolymer.

[0058] The bamboo fiber is sieved through a 40-100 mesh screen and dried at 100°C for 3 hours; then the above bamboo fiber and polypropylene are heated and mixed in a high-speed mixer, and the coupling agent, compatibilizer, Lubricant, nucleating agent and mixing aids are mixed uniformly, and the mixing temperature is controlled at 120°C and the rotating speed is 300r / min; after the mixing is evenly cooled to 40°C, a premix is obtained; the above premix is placed at a t...

Embodiment 3

[0060] Weigh the raw materials (parts by weight) according to the following weight:

[0061] 40 parts of bamboo fiber,

[0062] 50 parts of polyvinyl chloride,

[0063] Coupling agent KH560 1 part,

[0064] Compatibility agent POE-g-MAH 2.5 parts,

[0065] 1.5 parts of nucleating agent talcum powder,

[0066] Lubricant stearic acid 1 part,

[0067] 4 parts of mixing aids.

[0068] Among them, 1.6 parts of zinc oxide, 0.8 parts of antioxidant 1010, 0.8 parts of auxiliary antioxidant 168, and 0.8 parts of acrylate copolymer.

[0069] The bamboo fiber is sieved through a 40-100 mesh screen and dried at 95°C for 4 hours; then the above bamboo fiber and polyvinyl chloride are heated and mixed in a high-speed mixer, and the coupling agent and compatibilizer are added at the same time , Lubricant, nucleating agent and mixing aids are mixed uniformly, the mixing temperature is controlled at 110 ℃, the rotation speed is 180r / min; after the mixing is evenly cooled to 30 ℃, the premix is obtained; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com