Apparatus and method for recovering solvent in granulation of de-oiled asphalt with high softening point

A deoiled asphalt, high softening point technology, applied in the processing of tar asphalt/petroleum asphalt/natural asphalt, curing/crushing processing tar asphalt/petroleum asphalt/natural asphalt, petroleum industry, etc., to ensure smooth operation and simple equipment , the effect of short process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

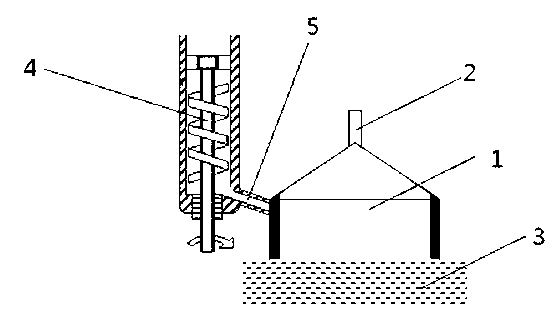

[0024] Taking butane solvent deasphalting as an example, a packed solvent deasphalting tower is used, the temperature of the tower, the tower, and the lower tower are 160°C, 153°C, and 145°C in sequence, and the residual oil is the vacuum residue of Saudi medium crude oil > 550°C Oil, agent oil volume ratio 4.5 / 1. The softening point of deoiled asphalt is 175°C when the amount of deasphalted oil extracted reaches 70%. This high softening point deoiled asphalt carries part of the solvent from the bottom of the tower into the screw rod to push the extrusion mechanical system. After extruding and granulating in the deoiled asphalt solvent separation chamber, the deoiled asphalt particles fall into the granules at a temperature of 25 through the slideway. The butane solvent gas (butane boiling point -0.522°C) collected in the deoiled asphalt solvent enrichment chamber will be liquefied by the solvent recovery system and continue to be used.

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com