Non-contact three-dimensional co-culture method for cells

A non-contact, co-culture technology, applied in the field of cell and tissue engineering, can solve the problems of limiting the research and development of cell co-culture, the inability to control the molecular weight cut-off of the membrane, and the difficulty of expanding the scale, so as to achieve a wide range of applications, avoid expensive materials and Process, the effect of ensuring biosafety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

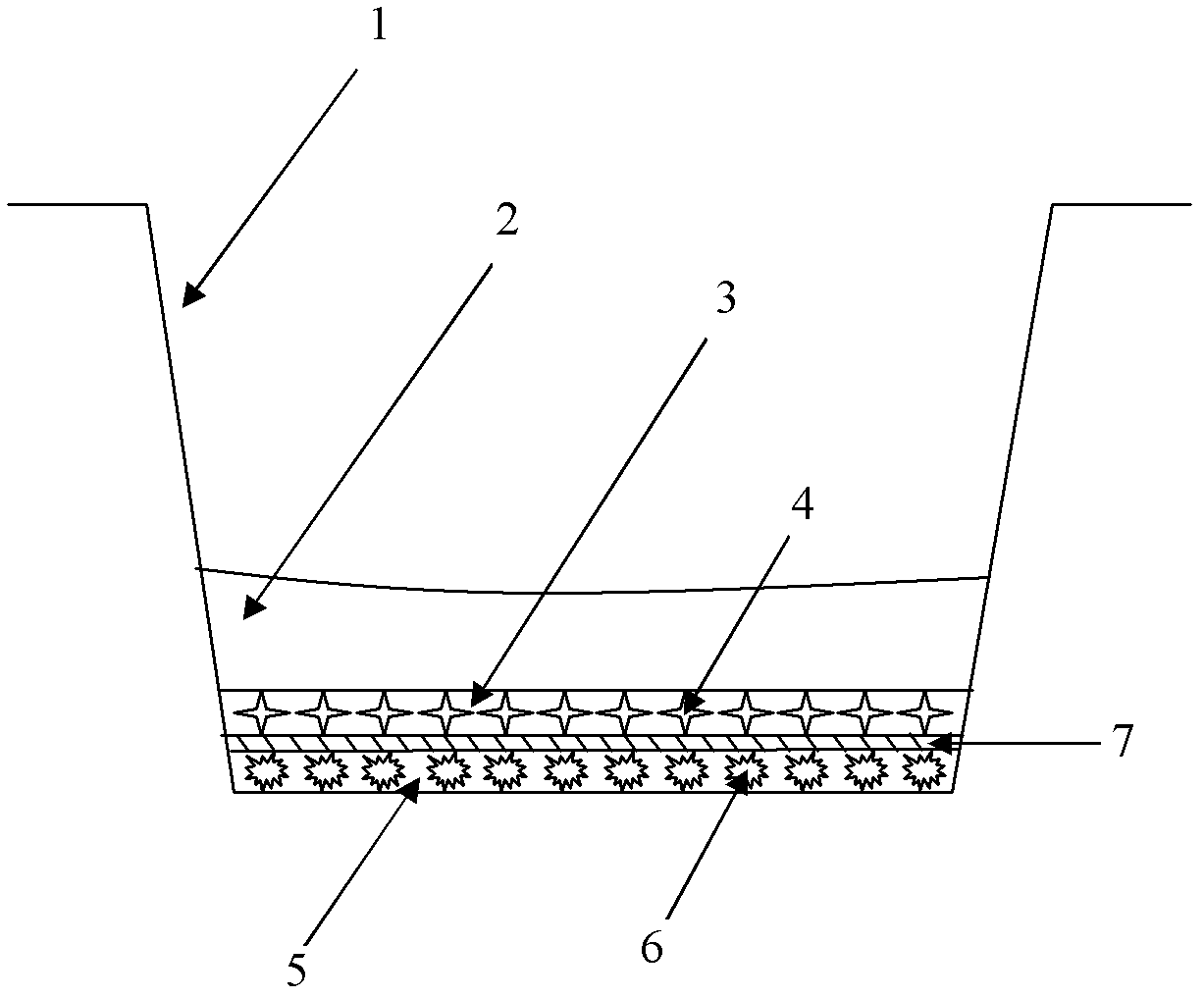

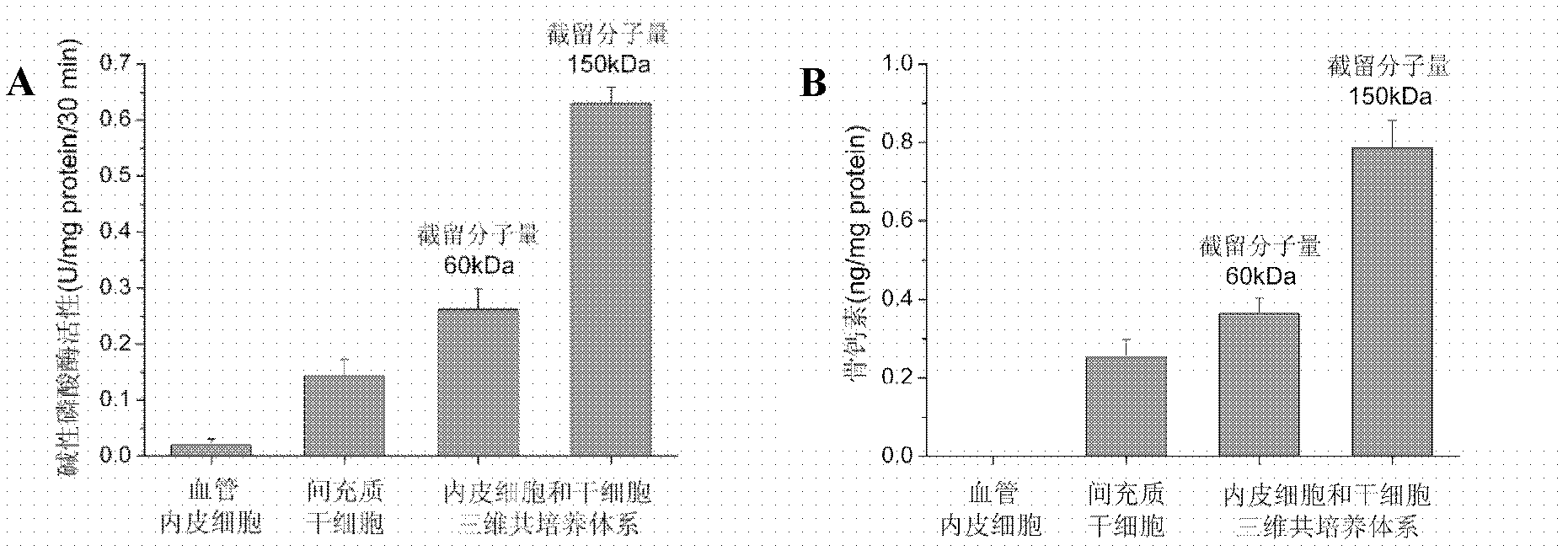

[0033] Example 1: Co-culture system regulates three-dimensional differentiation of bone marrow mesenchymal stem cells into osteoblasts

[0034] First, prepare arginyl-glycyl-aspartic acid (RGD) modified sodium alginate. Sodium alginate (molecular weight 430kDa, ratio of guluronic acid to mannuronic acid 1.5) was dissolved in 0.1M 2-(N-morpholino)ethanesulfonic acid (MES) buffer containing 0.5M NaCl (pH Value 6.5) to obtain a 1% (W / V) sodium alginate solution. Then, 1-(3-dimethylaminopropyl)-3-ethylcarbodiimide (EDC), N-hydroxysulfosuccinimide (sulfo-NHS) and RGD polypeptide were added, and the reaction was stirred at room temperature for 24 hours. The molar ratio of EDC to sodium alginate is 1:20, the molar ratio of EDC to sulfo-NHS is 2:1, and the mass ratio of RGD to sodium alginate is 1:1000. Then, it is dialyzed and freeze-dried to obtain RGD-modified sodium alginate.

[0035] After that, the fifth-generation vascular endothelial cells from SD rats were mixed with 1.5% (W / V)...

Embodiment 2

[0039] Example 2: Co-culture system improves renal epithelial cell activity after treatment with chemotherapeutics

[0040] The preparation of RGD modified sodium alginate is the same as in Example 1.

[0041] The 5th generation of SD rat bone marrow mesenchymal stem cells were mixed with 200 μL of physiological saline solution of 1.5% (W / V) RGD modified sodium alginate, and the cell density was adjusted to 5×10 6 cells·mL -1 , 200 μL of the cell suspension was slowly added to the culture wells of the 24-well plate to form a liquid film. After that, slowly add 100mmol·L -1 CaCl 2 500 μL of the solution was calcified for 20 minutes to obtain a calcium alginate gel layer. Then, add 500 μL of 0.5% (W / V) chitosan (molecular weight 150kDa, degree of deacetylation 90%) solution, and react to form a film for 15 minutes. After that, wash 3 times with normal saline and add 0.5μmol·L containing chemotherapy drugs -1 200μL of 1.5% (W / V) RGD-modified sodium alginate solution of renal tubular ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com