Process for recovering crude indium and tin from ITO (indium tin oxide) waste target

A target material and thick indium technology, applied in the field of ITO waste target material utilization, can solve the problems of low indium recovery rate and high content of tin indium, achieve high production efficiency, reduce indium content, and improve recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

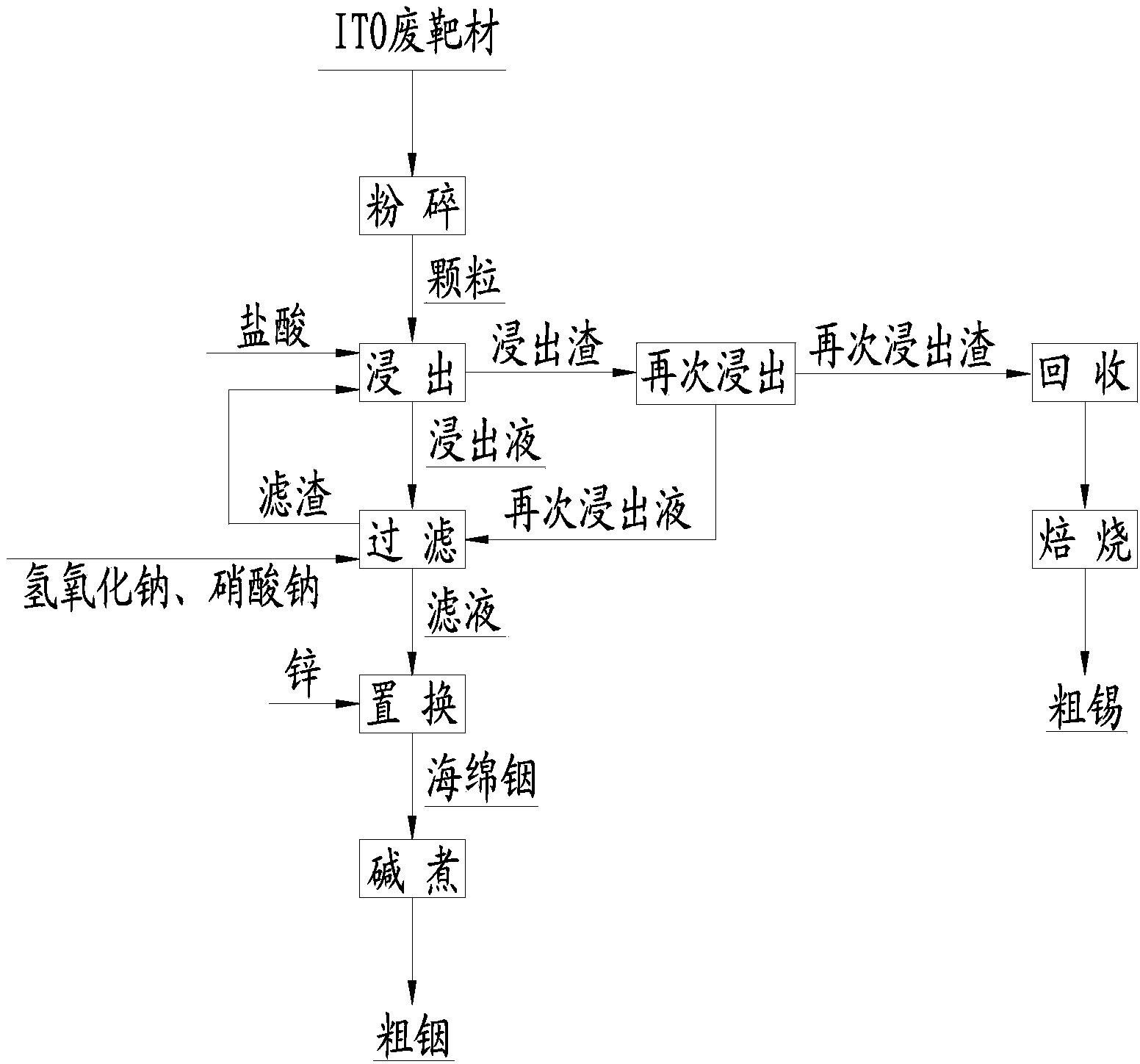

[0020] Combine below figure 1 The present invention is described in further detail:

[0021] The present invention comprises the following steps:

[0022] (1) Crush the waste ITO target material into particles; the waste ITO target material generally comes from scraps, chips, waste products, etc. generated during the production process of the target material, which contains about 74% indium and 7.8% tin, and the rest is oxygen and Trace impurities. During the implementation process, the waste target material can be crushed into particles below 1cm by using a pulverizer, which facilitates the rapid dissolution of indium in the waste target material in hydrochloric acid.

[0023] (2) Add the above particles into an appropriate amount of hydrochloric acid solution, stir evenly, and heat to leaching; the concentration of the hydrochloric acid solution is preferably 8mol / L-10mol / L, this concentration can make the leaching rate of indium greater than 95%, while that of tin The le...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com