Liquid crystal display device

A technology of liquid crystal display device and liquid crystal display panel, which is applied in the directions of instruments, optics, nonlinear optics, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

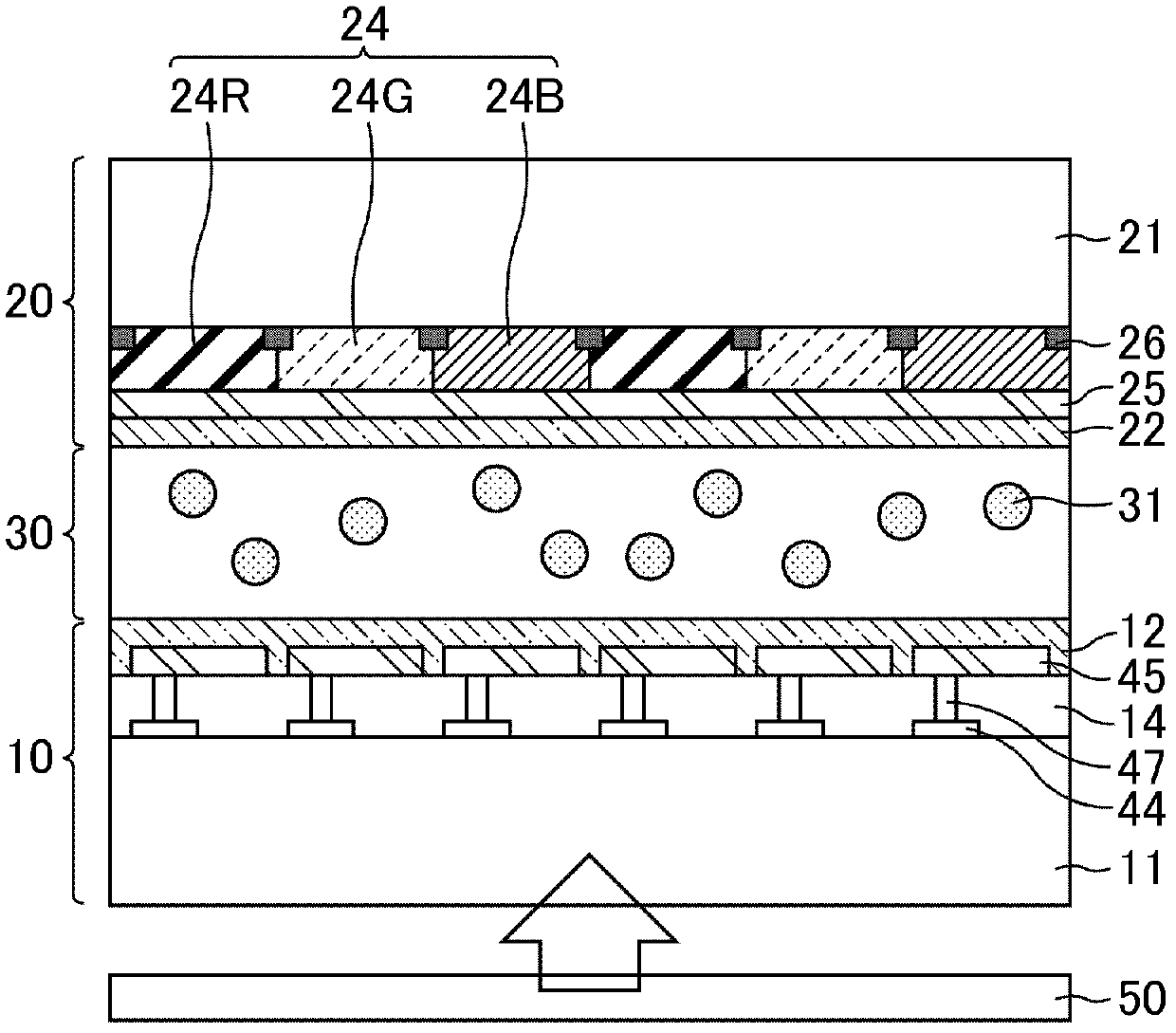

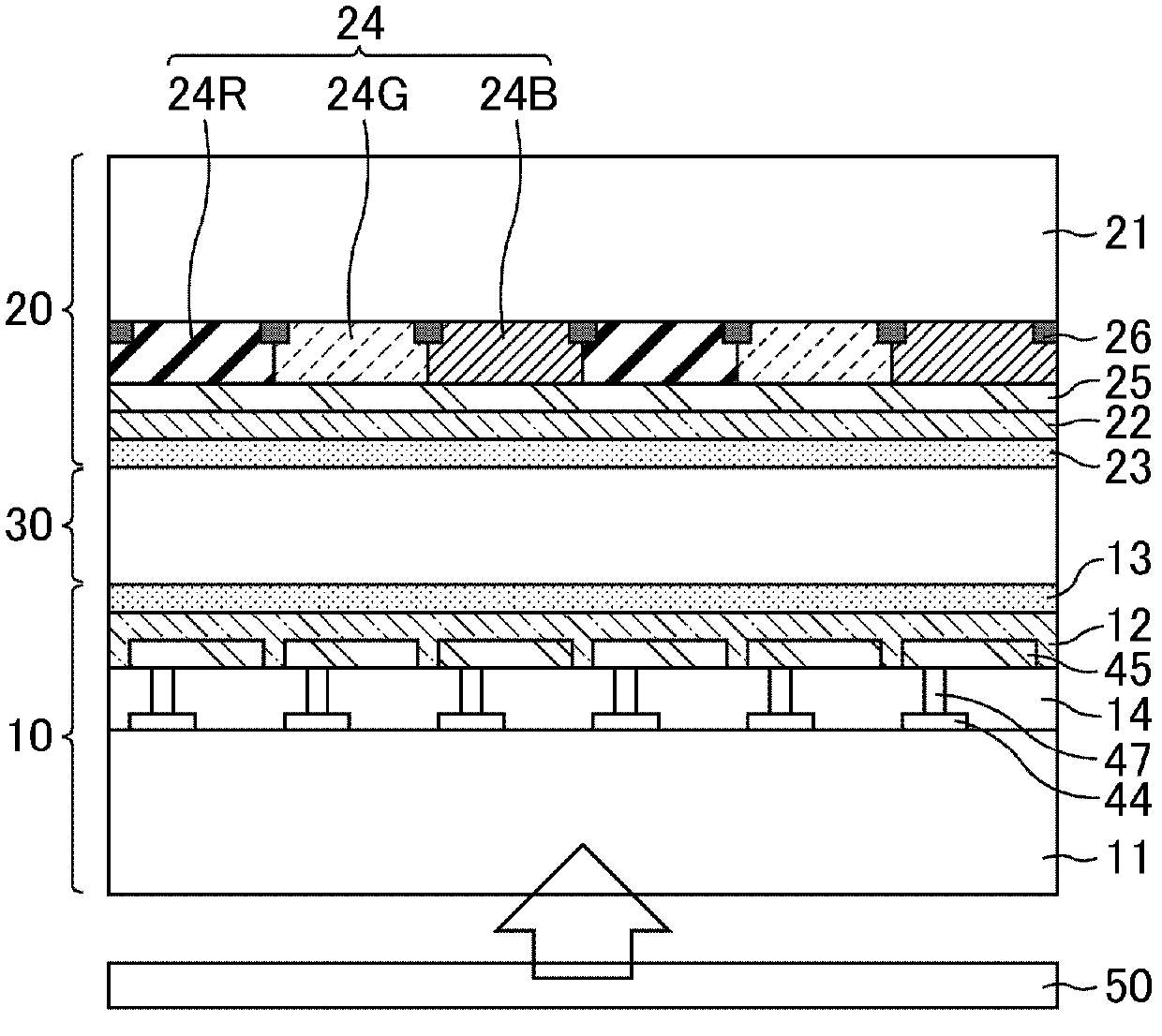

[0066] figure 1 and figure 2 is a schematic cross-sectional view of the liquid crystal display device according to the first embodiment. figure 1 Indicates that before the PSA polymerization process, figure 2 Indicates after the PSA polymerization step. Such as figure 1 and figure 2As shown, the liquid crystal display device of Embodiment 1 includes a liquid crystal display panel having an array substrate 10, an opposing substrate 20, and a liquid crystal sandwiched between a pair of substrates composed of the array substrate 10 and the opposing substrate 20. Layer 30. In addition, a backlight 50 is provided behind the liquid crystal display panel. The liquid crystal display device of Embodiment 1 performs display using light emitted from the backlight 50 . That is, the liquid crystal display device of Embodiment 1 is a transmissive liquid crystal display device.

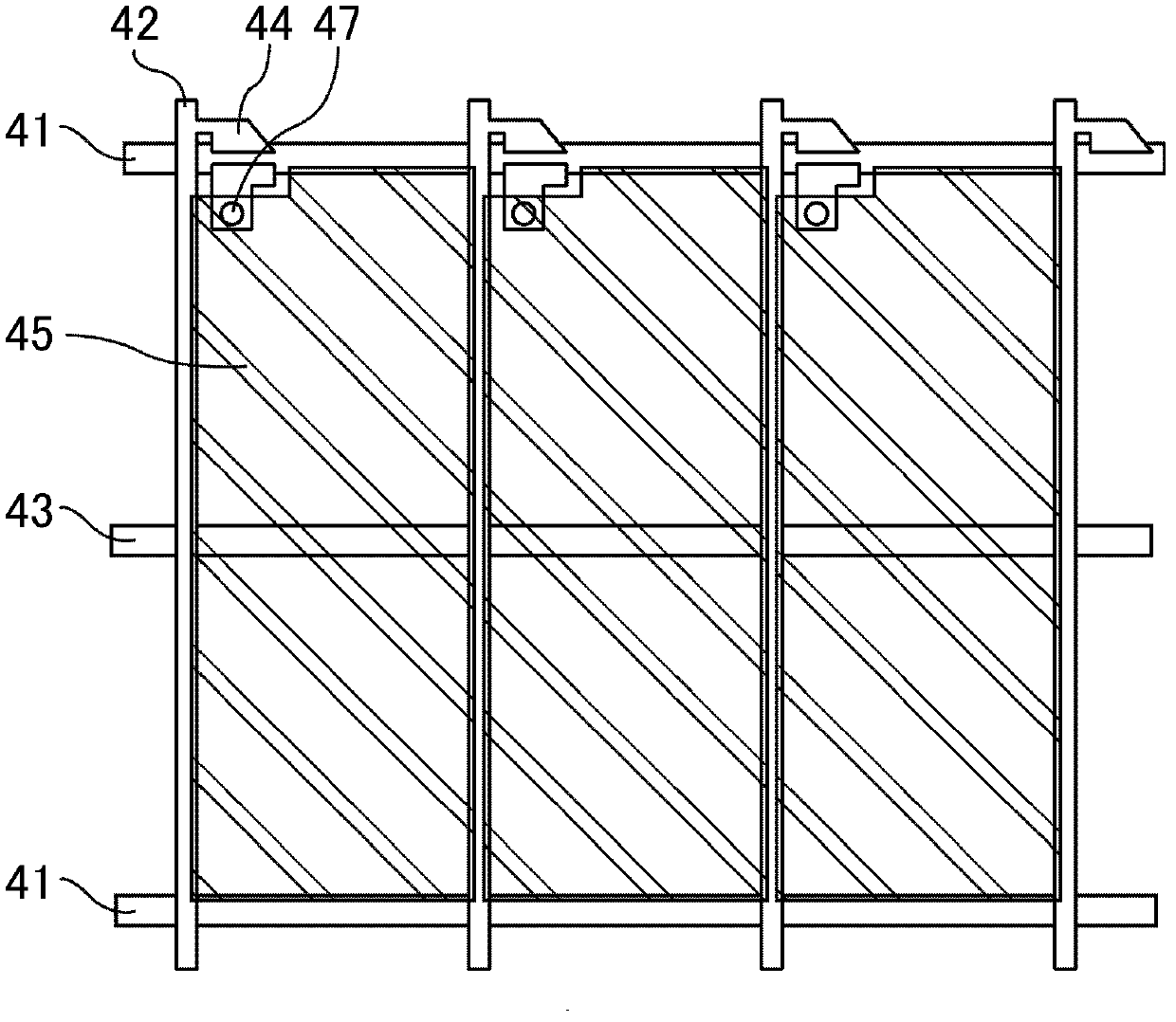

[0067] The array substrate 10 includes: an insulating transparent substrate 11 made of glass or the...

Embodiment 1

[0096] The liquid crystal display panel of Embodiment 1 was actually manufactured, and the afterimage of the display was confirmed. The light source used in embodiment 1 is to have Figure 9 and Figure 10 The LEDs of the light emission spectrum shown do not have substantially any light having a wavelength below 400 nm. On the other hand, using the Figure 9 and Figure 10 In the CCFL with the emission spectrum shown, a very small peak (about 0.04 μW / cm 2 ).

[0097] First, a pair of substrates consisting of an array substrate and a counter substrate is prepared, a composition for forming a liquid crystal layer containing a liquid crystal material and a monomer for forming a PSA layer is dropped, and then bonded to the other substrate. The color filter is fabricated on the opposite substrate.

[0098] In Example 1, as a monomer for PSA layer formation, a compound represented by the following chemical formula (3) was used:

[0099]

[0100] The compound represented by...

Embodiment approach 2

[0108] The liquid crystal display device according to Embodiment 2 is in the form of a color filter array (COA: Color Filter On Array) formed on an array substrate instead of a color filter on an opposing substrate, and the light source is not limited to LEDs. Other than that, it is the same as Embodiment 1.

[0109] Figure 6 and Figure 7 is a schematic cross-sectional view of a liquid crystal display device according to Embodiment 2. FIG. Figure 6 Indicates that before the PSA polymerization process, Figure 7 Indicates after the PSA polymerization step. Such as Figure 6 and Figure 7 As shown, in the second embodiment, the color filter 24 and the black matrix 26 are formed on the array substrate 10 . More specifically, TFT 44 and bus lines (not shown) are arranged on an insulating transparent substrate 11 made of glass or the like, and black matrix 26 and color filters are arranged thereon via an insulating film (not shown). twenty four. In some cases, another in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com