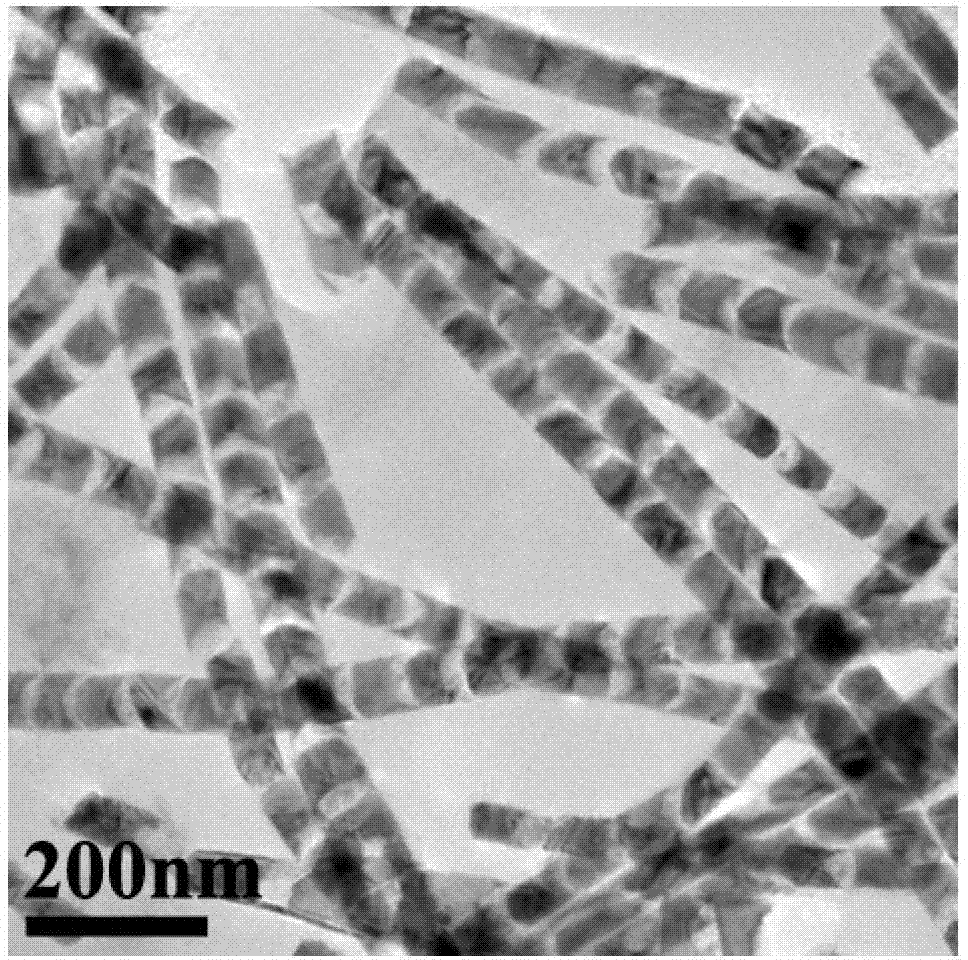

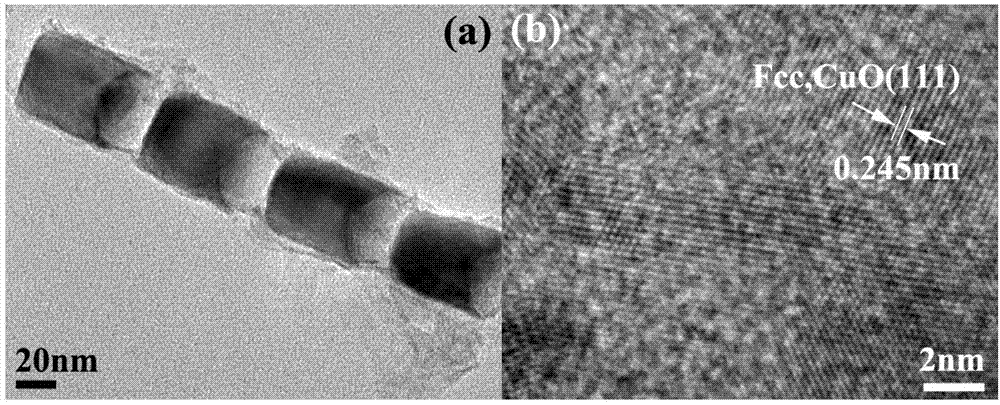

Nano chain composed by metallic nickel particles connected by copper oxide fimls and preparation method thereof

A technology of metal nickel and copper oxide, applied in nanotechnology, nanotechnology, nanotechnology, etc. for materials and surface science, can solve the problem of unfavorable biomolecular addition, high specific surface area of nickel magnetic particles, limited specific surface area, etc. problem, to achieve the effect of expanding the field and scope, scientific preparation method, and high specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The concrete steps of preparation are:

[0025] Step 1: first use the anodic oxidation method on the aluminum sheet to obtain a through-hole alumina template with a hole diameter of 45nm, and then vapor-deposit a gold film with a thickness of 150nm on one side of the through-hole alumina template.

[0026] In step 2, the aluminum oxide template with a gold film evaporated on one side is used as the cathode, and is placed in the copper electrolyte and the nickel electrolyte for 6 alternate electrodepositions; wherein, each time the electrodeposition in the copper electrolyte is The voltage is 0.8V, the deposition time is 30s, the deposition voltage is 2V, and the deposition time is 45s each time in nickel electrolyte, the anode during electrodeposition is a graphite electrode, and it is placed in the Washing in deionized water to obtain an aluminum oxide template with alternately connected copper pillars and nickel pillars placed in the holes and gold film evaporated on ...

Embodiment 2

[0029] The concrete steps of preparation are:

[0030] Step 1: first use the anodic oxidation method on the aluminum sheet to obtain a through-hole alumina template with a hole diameter of 48nm, and then vapor-deposit a gold film with a thickness of 180nm on one side of the through-hole alumina template.

[0031] In step 2, the aluminum oxide template with a gold film evaporated on one side is used as the cathode, and is placed in the copper electrolyte and the nickel electrolyte for 11 alternate electrodepositions; wherein, each time the electrodeposition in the copper electrolyte is The voltage is 0.9V and the deposition time is 25s. The deposition voltage is 2.1V and the deposition time is 35s each time in nickel electrolyte. The anode during electrodeposition is a graphite electrode. Wash in deionized water to obtain an aluminum oxide template with alternately connected copper pillars and nickel pillars placed in the holes and gold film evaporated on one side.

[0032]Ste...

Embodiment 3

[0034] The concrete steps of preparation are:

[0035] Step 1: first use the anodic oxidation method on the aluminum sheet to obtain a through-hole alumina template with a hole diameter of 50 nm, and then vapor-deposit a gold film with a thickness of 200 nm on one side of the through-hole alumina template.

[0036] In step 2, the aluminum oxide template with a gold film evaporated on one side is used as the cathode, and placed in the copper electrolyte and the nickel electrolyte for 16 alternate electrodepositions; wherein, each time the electrodeposition in the copper electrolyte is The voltage is 1V and the deposition time is 20s. The deposition voltage is 2.2V and the deposition time is 25s each time in nickel electrolyte. The anode during electrodeposition is a graphite electrode. After each electrodeposition, it is placed Wash in deionized water to obtain an aluminum oxide template with alternately connected copper pillars and nickel pillars placed in the holes and gold f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com