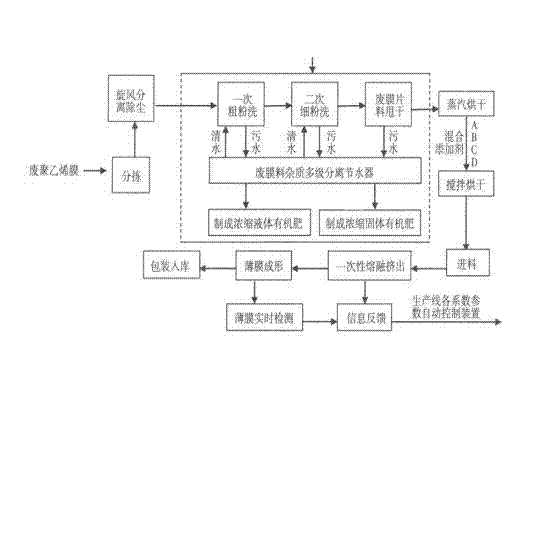

Preparation process of one-time fused and regenerated polyethylene agricultural plastic mulching film

A technology of recycled polyethylene and agricultural mulch, which is applied in the field of agrochemicals, can solve problems such as low added value, imperfect technology, and failure to meet the use requirements, and achieve the effects of energy saving, process reduction, and environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

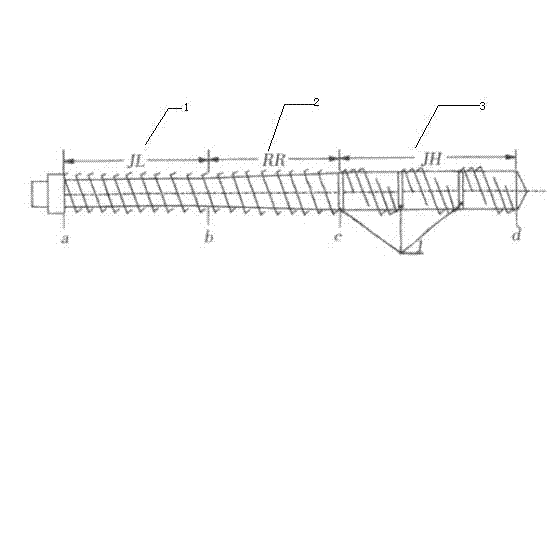

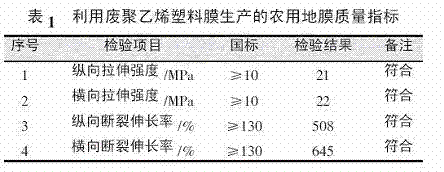

[0016] Firstly, the polyethylene agricultural mulch waste film material is pretreated, coarsely crushed and washed, and finely crushed into waste film sheets with an average diameter of no more than 8 mm, washed and dried; then additives are added to improve the physical and chemical properties of the material in the blow molding machine Performance and status, after stirring and drying, with the help of a screw with "one loose and one tight" thread structure (for loose and tight screws, see the attached figure 2 ) Feed extrusion, melting and blow molding to obtain film-making products. The mass proportion of additive and waste film material is 1.2‰: 998.8‰, and additive is made of sodium bicarbonate, powdery low-pressure polyethylene, powdery polypropylene and composite additive according to the following mass proportion: sodium bicarbonate: powdery Low-pressure polyethylene: powdered polypropylene: composite auxiliary agent = 0.8: 1.0: 1.2: 3.0, wherein the composite auxilia...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com