Titanium hydride-type high-energy composite explosive and preparation method thereof

A technology of mixed explosives and titanium hydride, which is applied in the direction of explosives, etc., can solve the problems of poor compatibility between magnesium hydride and RDX, unstable chemical properties of magnesium hydride, difficulties in storage and transportation of explosives, etc., and achieve good insensitivity effect, Good stability and storability, high thermal decomposition critical temperature effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

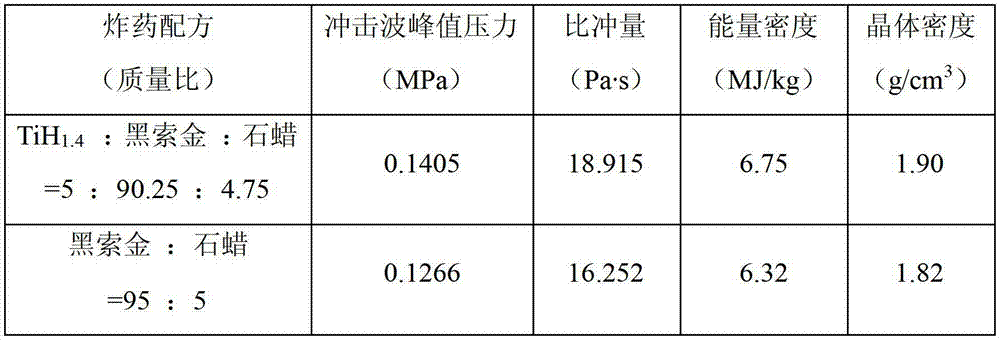

Embodiment 1

[0021] The high-energy mixed explosive of this embodiment is made of the following mass percentage components: TiH 1.4 Powder 5%, RDX 90.25%, paraffin 4.75%. where TiH 1.4 The average particle size of the powder is 45 μm.

[0022] The specific preparation method of this high-energy mixed explosive of the present embodiment is as follows:

[0023] ① Weigh each component: TiH 1.4 5g, RDX 90.25g, paraffin 4.75g;

[0024] ② TiH 1.4 The powder is heated at 110°C for 2 hours, dried and passivated;

[0025] ③ Completely passivate RDX and paraffin at 90°C;

[0026] ④The passivated TiH 1.4 The powder is mixed with passivated RDX and stirred uniformly to obtain the high-energy mixed explosive of this embodiment.

[0027] For comparative experiments, 20g of high-energy mixed explosives and 20g of passivated RDX were taken to make cylindrical charges for air explosion test. The size of the drug pack is: diameter 26.5mm, height 22.1mm. Experimental conditions: the sensor and the ...

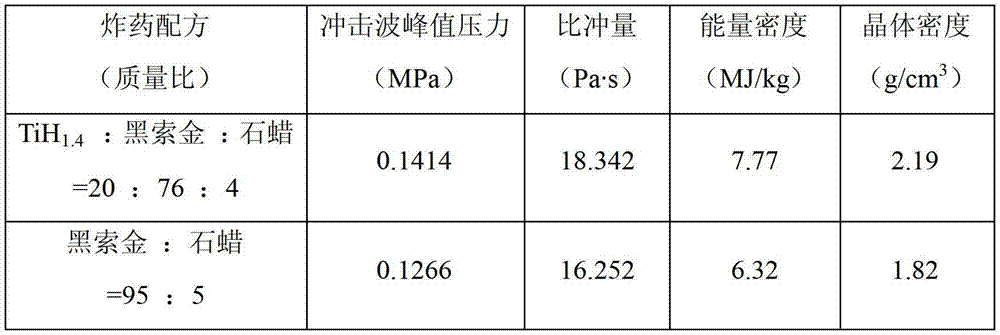

Embodiment 2

[0031] The high-energy mixed explosive of this embodiment is made of the following mass percentage components: TiH 1.4 20% powder, 76% RDX, 4% paraffin. where TiH 1.4 The average particle size of the powder is 45 μm.

[0032] The specific preparation method of this high-energy mixed explosive of the present embodiment is as follows:

[0033] ① Weigh each component: TiH 1.4 20g, RDX 76g, paraffin 4g;

[0034] ② TiH 1.4 The powder is heated at 110°C for 2 hours, dried and passivated;

[0035] ③ Completely passivate RDX and paraffin at 90°C;

[0036] ④The passivated TiH 1.4 The powder is mixed with passivated RDX and stirred uniformly to obtain the high-energy mixed explosive of this embodiment.

[0037] For comparative experiments, 20g of high-energy mixed explosives and 20g of passivated RDX were taken to make cylindrical charges for air explosion test. The size of the drug pack is: diameter 26.5mm, height 22.1mm. Experimental conditions: The sensor and the drug package...

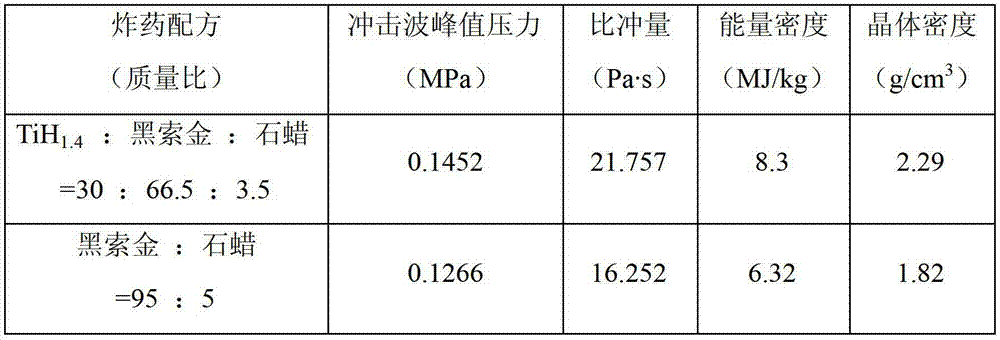

Embodiment 3

[0041] The high-energy mixed explosive of this embodiment is made of the following mass percentage components: TiH 1.4 Powder 30%, RDX 66.5%, paraffin 3.5%. where TiH 1.4 The average particle size of the powder is 45 μm.

[0042] The specific preparation method of this high-energy mixed explosive of the present embodiment is as follows:

[0043] ① Weigh each component: TiH 1.4 30g, 66.5g of RDX, 3.5g of paraffin;

[0044] ② TiH 1.4 The powder is heated at 110°C for 2 hours, dried and passivated;

[0045] ③ Completely passivate RDX and paraffin at 90°C;

[0046] ④The passivated TiH 1.4 The powder is mixed with passivated RDX and stirred uniformly to obtain the high-energy mixed explosive of this embodiment.

[0047] For comparative experiments, 20g of high-energy mixed explosives and 20g of passivated RDX were taken to make cylindrical charges for air explosion test. The size of the drug pack is: diameter 26.5mm, height 22.1mm. Experimental conditions: The sensor and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com