Simulation experiment method and system for thermal treatment of oily sludge

A technology for simulating experiments and sludge, applied in the field of oily sludge heat treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

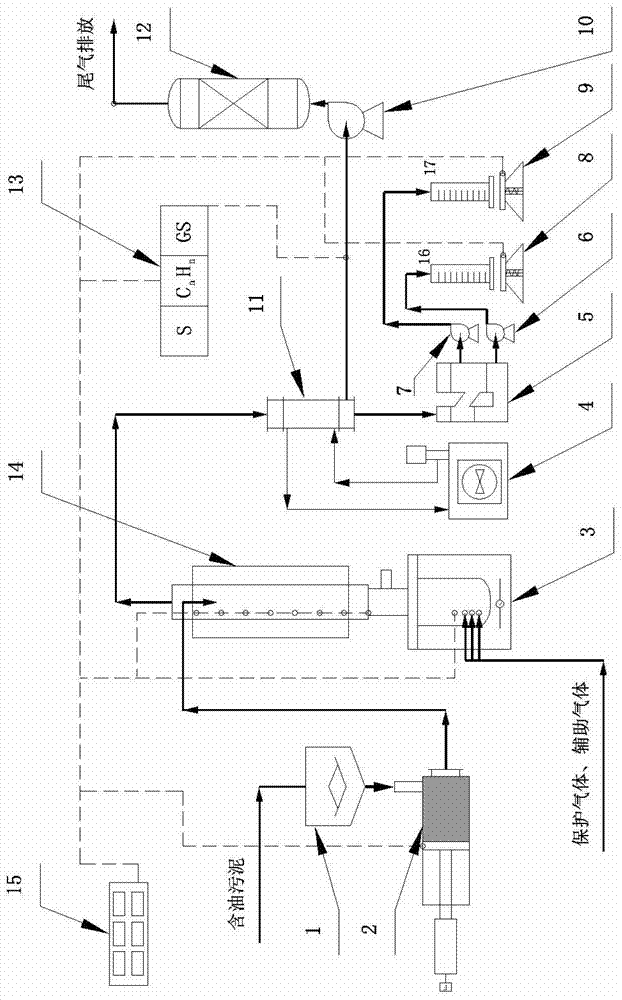

[0050] This embodiment provides a simulation experiment system for heat treatment of oily sludge, its structure is as follows figure 1 As shown, the system includes a homogenizer 1, a sludge booster conveyor 2, a mass transfer heat transfer reactor 14, a heating furnace 3, a circulating cooling water device 4, an automatic oil-water separation device 5, and a first liquid level control pump 6 , the second liquid level control pump 7, pyrolysis water metering electronic scale 8, water collection container 16, pyrolysis oil metering electronic scale 9, oil collection container 17, induced draft fan 10, distillate condenser 11, thermal oxidation tower 12 , Online gas component detector 13, detection and control device 15, wherein:

[0051] The homogenizer 1 is provided with a material inlet and an outlet, and its outlet is connected to the inlet of the sludge pressurized conveyor 2;

[0052] The sludge booster conveyor 2 is connected to the top feed port of the mass transfer hea...

Embodiment 2

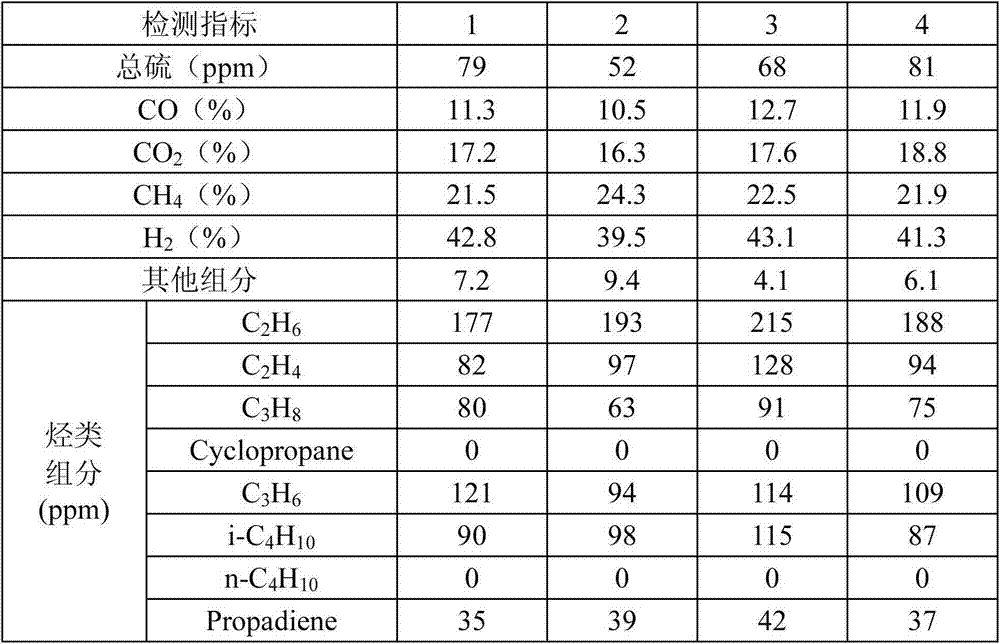

[0061] This embodiment provides a simulation experiment method for heat treatment of oily sludge, which is a method for analyzing oily sludge samples using the simulation experiment system for heat treatment of oily sludge provided in Example 1, including the following steps:

[0062] 40kg of oily sludge was placed in the homogenizer 1 and stirred for 30 minutes. Three samples were taken for detection: the water content was 75.1%, 75.2%, and 74.8%; the oil content was 13.6%, 13.4%, and 13.5%; the relative error is less than 4%, it is considered that the sludge is evenly mixed, and the experiment is continued;

[0063] Turn on the power supply of auxiliary systems such as the induced draft fan 10, the circulating cooling water device 4, the pyrolysis water metering electronic scale 8, the pyrolysis oil metering electronic scale 9 and the thermal oxidation tower 12, open the operating system, and check whether the remote signals are normal;

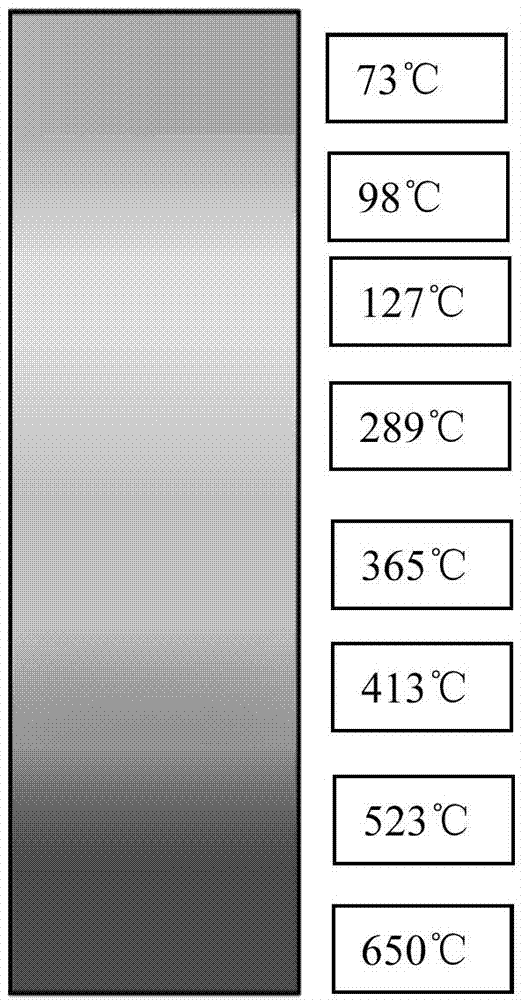

[0064] Open the heating furnace 3, h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com