Filter material for filter element, preparation method and application of filter material

A filter material and filter element technology, which is applied in the field of filter element filter material and its production and application, can solve the problems of low carbon, three wastes, complex process, etc., and achieve good flame retardancy, simple and environmentally friendly production process, and high capture efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

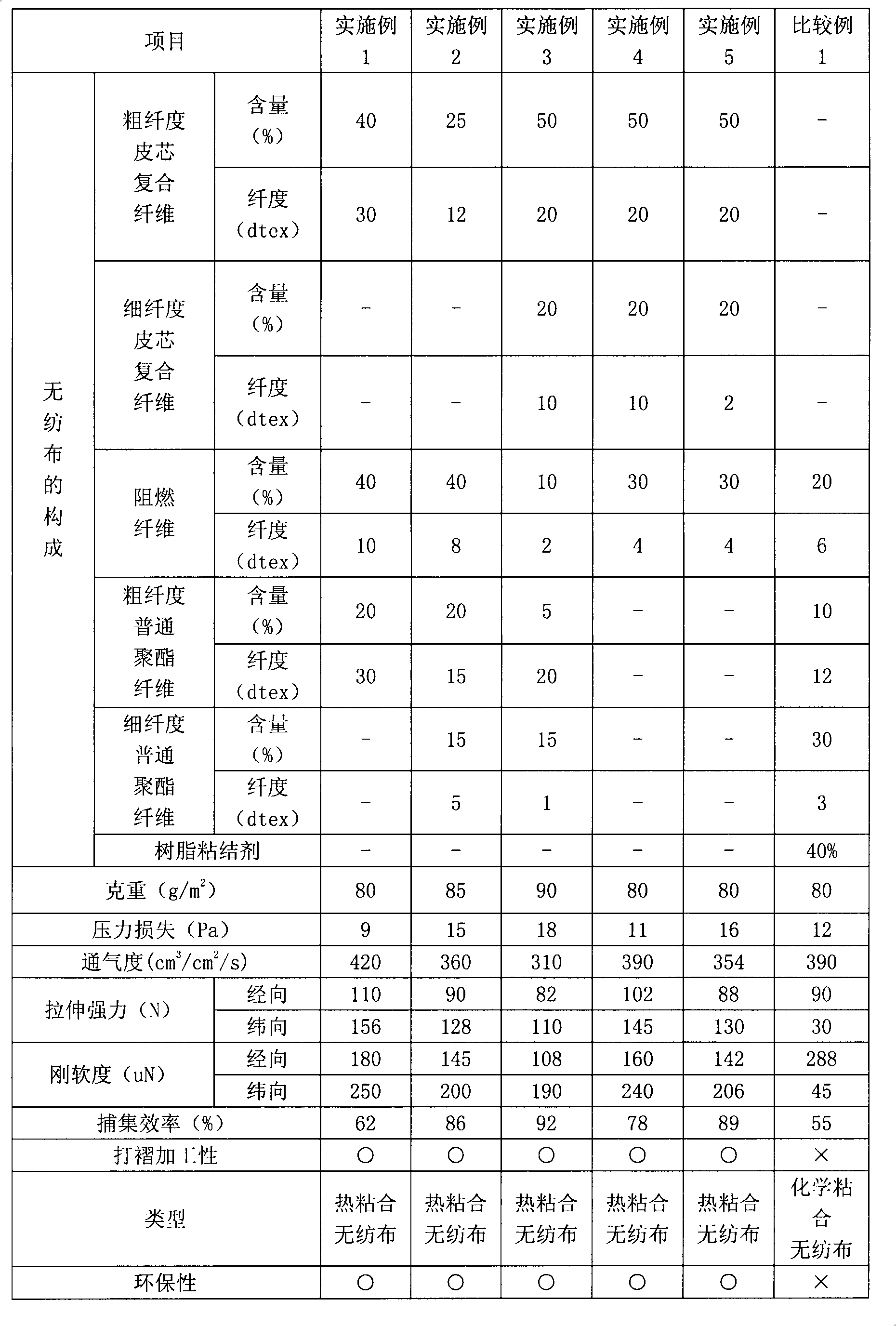

Embodiment 1

[0035] 40% by weight of fineness of 30dtex coarse sheath-core composite fiber, 40% by weight of fineness of 10dtex flame-retardant fiber and 20% by weight of fineness of 30dtex ordinary polyester fiber of coarse fineness are used for feeding, after opening, carding Cotton and cross-lapping form a composite fiber web layer, wherein the skin component in the sheath-core composite fiber is a copolyester fiber with a melting point of 110 ° C, and the core component is a common polyester fiber. The fiber web layer obtained above is 7 m / min Speed, thermal bonding through a 1.5-meter hot air box at a temperature of 180 ° C, and then at a pressure of 75 kg / cm 2The hot metal rolls with the upper and lower temperatures of 150°C are used for hot pressing and reinforcement, and the grammage is 80g / m 2 The heat-bonded non-woven fabric of the above-mentioned non-woven fabric is used to make the filter material for the filter core of the present invention. The physical properties of the obt...

Embodiment 2

[0037] With 25% by weight of coarse fiber of 12 dtex, 40% by weight of flame retardant fiber of 8 dtex, 20% by weight of coarse polyester fiber of 15 dtex and 15% by weight of fiber of 5 dtex Feed the ordinary polyester fiber with a fineness of fineness, and form a composite fiber network layer through opening, carding, and cross-lapping. The skin component of the sheath-core composite fiber is copolyester fiber with a melting point of 110°C, and the core component is ordinary polyester. Fiber, the above-mentioned obtained fiber web layer is thermally bonded by a 2-meter hot air box with a temperature of 190 °C at a speed of 9 m / min, and then heated at a pressure of 80 kg / cm 2 The hot metal rolls with the upper and lower temperatures of 155°C are used for hot pressing and reinforcement, and the grammage is 85g / m 2 The heat-bonded non-woven fabric of the above-mentioned non-woven fabric is used to make the filter material for the filter core of the present invention. The physi...

Embodiment 3

[0039] 50% by weight of thick sheath-core composite fiber with a fineness of 20dtex, 20% by weight of finer sheath-core composite fiber with a fineness of 10dtex, 10% by weight of flame-retardant fiber with a fineness of 2dtex, and 5% by weight of a finer fiber with a fineness of 20dtex 15% by weight of ordinary polyester fibers with a coarse fineness of 1dtex and 15% by weight of ordinary polyester fibers with a fine fineness of 1dtex are fed, and a composite fiber web layer is formed through opening, carding, and cross-lapping, wherein the sheath composition of the skin-core composite fiber is The copolyester fiber with a melting point of 110°C and the core component is ordinary polyester fiber. The fiber web layer obtained above is thermally bonded by a 3-meter hot air box with a temperature of 200°C at a speed of 10 m / min. 85kg / cm 2 The hot metal rolls with the upper and lower temperatures of 160°C are used for hot pressing and reinforcement, and the grammage is 90g / m 2 T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com