External auxiliary heating frosting-proof capillary throttling integrated device

A capillary and auxiliary heating technology, applied in the direction of fluid circulation arrangement, damage protection, refrigeration and liquefaction, etc., can solve the problems of poor indoor environment, insufficient heat refrigerant, ice accumulation, etc., to improve system operation performance and refrigerant energy , The effect of increasing the evaporation temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

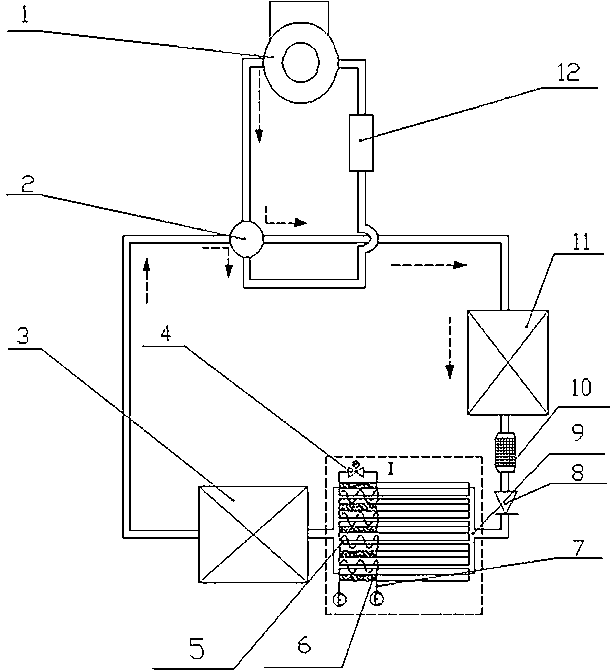

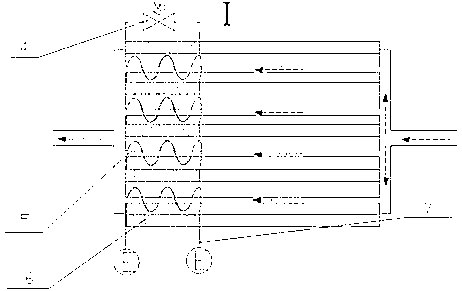

[0032] Embodiments of the present invention are carried out on site according to figure 1 It can be completed, and the structure is simple and practical. It is a schematic diagram of an external auxiliary heating anti-defrosting capillary throttling integrated device based on the multi-parameter frost growth law. The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments. Schematic diagram of the system structure of the present invention figure 1 and figure 2 Among them:

[0033] see figure 1 , figure 1 It expresses the flow direction of the refrigerant under the heating condition. When the system starts to operate under the heating condition under the condition of low temperature, high humidity and easy frosting, the electric heating element is energized, and the outlet of the compressor 1 passes through the four-way reversing valve. After 2, the high-temperature and high-pressure refrigerant gas passes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com