X-ray detector

A technology of ray detection and detection device, which is applied in the field of X-ray detection optical devices, can solve the problems of difficult detection, unclear image, large noise, etc., and achieve the effect of simple structure and clear imaging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in further detail below.

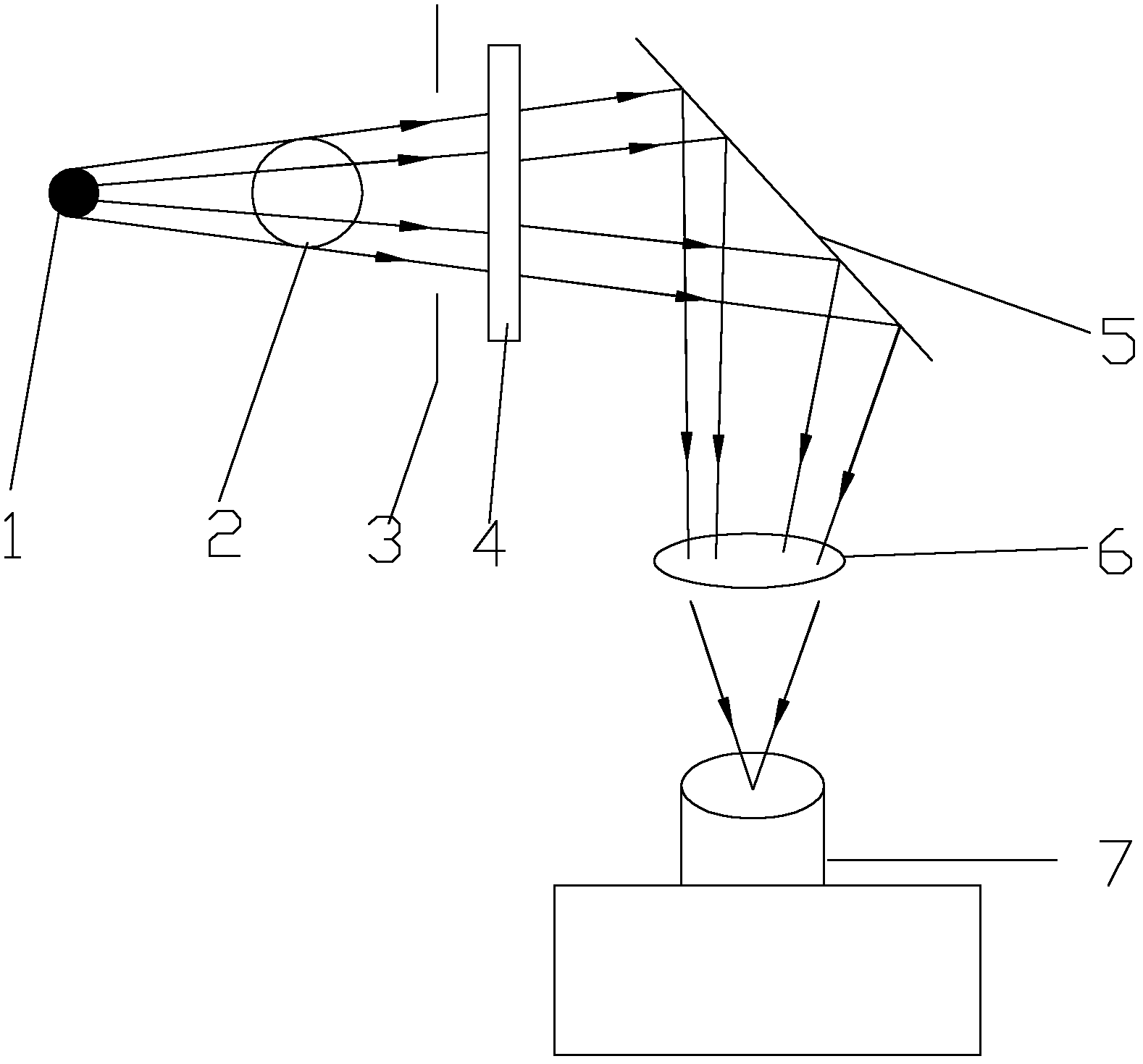

[0014] With reference to accompanying drawing, X-ray detecting device is made up of x-ray source 1, visible light conversion screen 4, aperture 3, plane mirror 5, convex lens 6 and CCD image sensor 7, is characterized in that, x-ray source 1, aperture 3 and the visible light conversion screen 4 are sequentially arranged directly in front of the plane mirror 5, and the bottom of the plane mirror 5 is sequentially provided with a convex lens 6 and a CCD image sensor 7;

[0015] A measured object 2 is arranged between the x-ray source 1 and the diaphragm 3;

[0016] The aperture 3 can remove stray light in the device;

[0017] The surface of the plane mirror 5 is coated with a high reflection film;

[0018] When the x-rays pass through the measured object 2, use the aperture 3 to remove stray light in the device, and when the x-rays pass through the visible light conversion screen 4, the x-ray image can b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com