Preparation method of non-photosensitive polyimide passivation layer

A polyimide, non-photosensitive technology, applied in the field of preparation of non-photosensitive polyimide passivation layer, can solve the problems of uncontrollable, unfavorable device miniaturization, and affecting the performance of semiconductor devices 1, etc., to meet different requirements The needs of product technology and the effect of facilitating the needs of different product technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to have a more specific understanding of the technical content, characteristics and effects of the present invention, now in conjunction with the illustrated embodiment, the details are as follows:

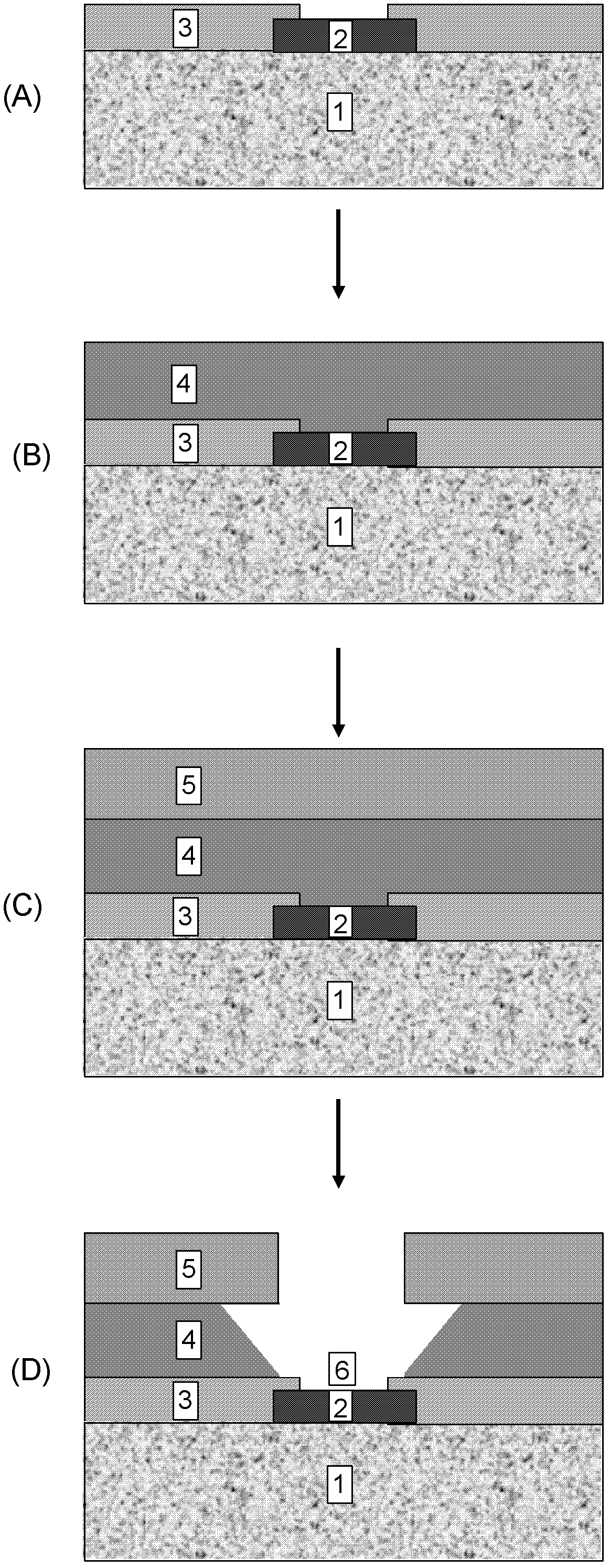

[0034] Such as image 3 Shown, the preparation method of non-photosensitive polyimide passivation layer of the present invention, its main processing step is as follows:

[0035] Step 1, on semiconductor device 1, form the pattern of top layer metal aluminum line 2 and dielectric layer passivation film 3, as image 3 (A) shown. The dielectric layer passivation film 3 can be silicon nitride, silicon oxynitride, silicon dioxide or any combination thereof. According to the specific requirements of the process, the pattern of the passivation film 3 of the dielectric layer may not be formed.

[0036] Step 2, spin coating and baking a layer of non-photosensitive polyimide 4 with a thickness a (a is 1 to 50 microns) on the semiconductor device 1 on which the top layer ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com