Wrapper of stuffing flour product as well as preparation method and application of wrapper

A technology for dough and pasta, which is applied to the dough of frozen stuffed pasta products and the preparation thereof, the dough of stuffed pasta products and the field of preparation thereof, can solve the problems of difficult large-scale application, general product quality, difficult operation and the like, and achieves the Easy to operate, better taste, good water retention effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

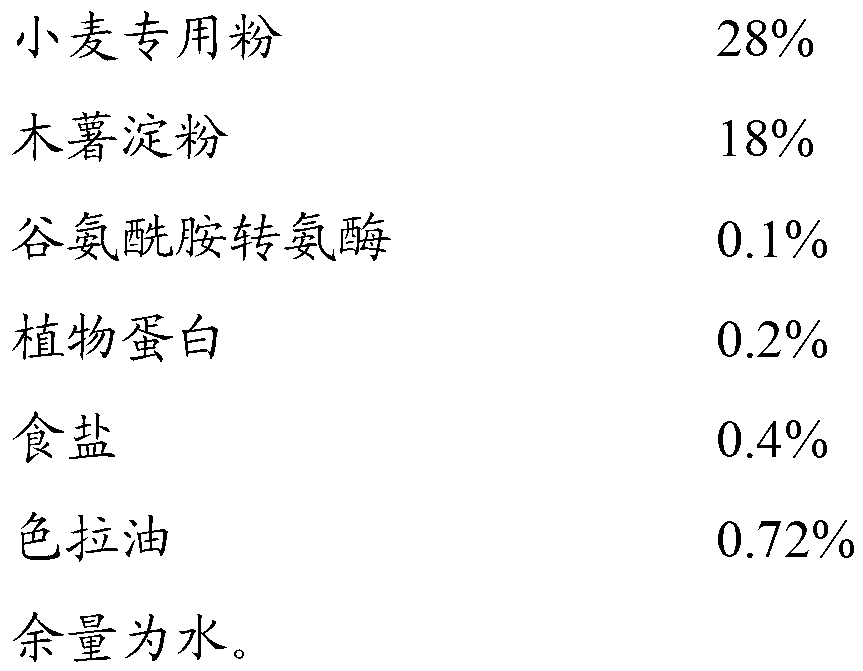

[0043] One, the preparation technology of frozen dumpling

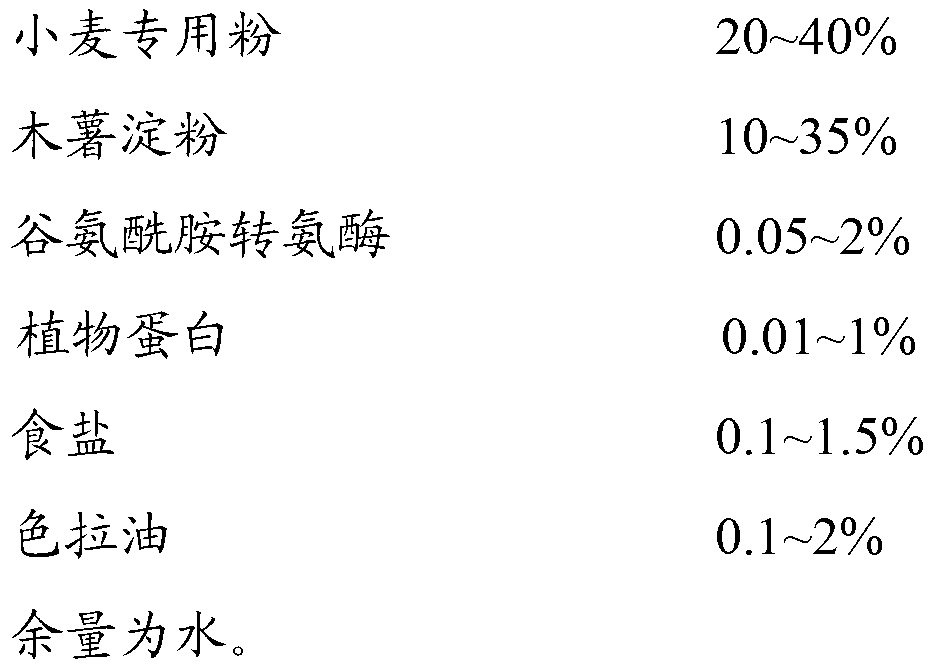

[0044] ①Mix and knead dough: at room temperature, mix special wheat flour, tapioca starch (Zhengzhou Chenyang Chemical Co., Ltd.), glutamine transaminase (Shanghai Jienuo Biotechnology Co., Ltd.), wheat plant protein (Shanghai Jienuo Biotechnology Co., Ltd. ), salt and salad oil are mixed evenly in the mixer according to the ratio, and then placed in a two-speed dough mixer for 15 minutes;

[0045] ②Static enzymatic hydrolysis: put the dough neutralized in step ① at 35°C for 60 minutes to fully enzymatically hydrolyze.

[0046] ③Press forming: the enzymatically hydrolyzed dough is pressed into a dough with a roller-type noodle press, and the thickness of the dough is 1.0mm;

[0047] ④ Filling: put stuffing in the dough to make dumplings;

[0048] ⑤Steaming: Steam the wrapped dumplings in a steamer for 10 minutes and let cool to room temperature;

[0049] ⑥ Freezing: Place the finished dumplings in a -18°C refrigera...

Embodiment 1

[0059] Adopt the freezing dumpling craft that above-mentioned dough is made, get the wheat starch of 20%, the cassava starch of 35% and 0.05% glutamine transaminase, the wheat plant protein of 0.01%, the salt of 1.5% and the salad oil of 0.1% to take mass percent to use After the mixer is fully mixed evenly, add water with a balance of 43.34% at room temperature and knead the dough in the two-speed dough mixer for 15 minutes. After kneading the dough, put the dough at 35°C for 60 minutes and then press it. Frozen dumplings are made after the dough skin, stuffing, freezing and other processes. The state of the frozen dumplings made by this process was subjected to sensory evaluation and freezing cracking after 10 days, 1 month, 2 months, 3 months, 4 months, 5 months and 6 months after freezing storage. Determination of rate and broken belly rate after cooking.

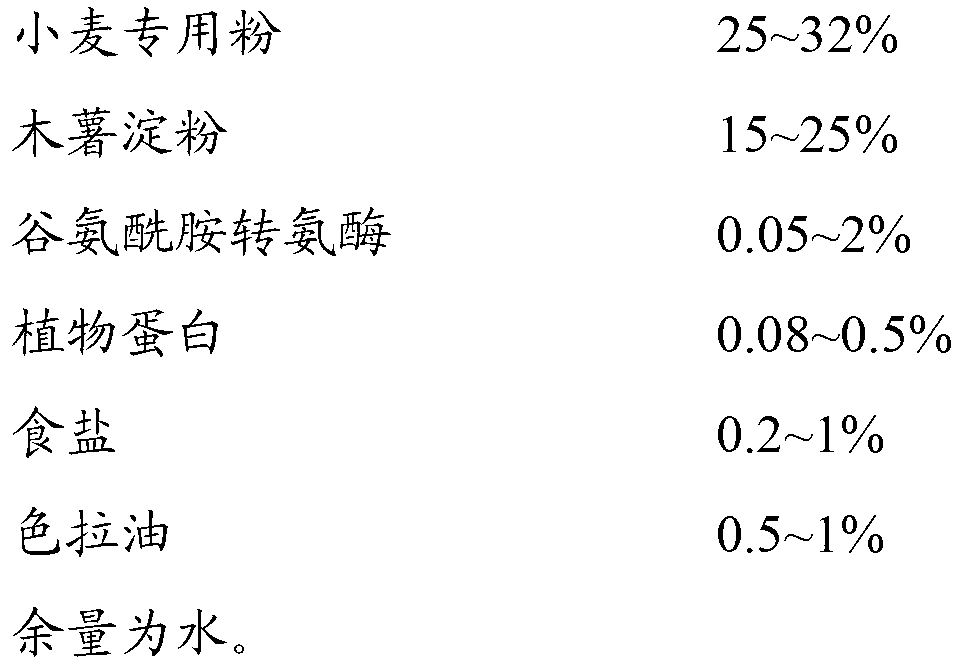

Embodiment 2

[0061] Adopt the frozen dumpling craft that above-mentioned dough is made, get the wheat starch of 25%, the cassava starch of 30% and 2% transglutaminase, the wheat plant protein of 0.5%, the salt of 1.2% and the salad oil of 0.5% to take mass percent After the mixer is fully mixed evenly, add water with a balance of 40.8% at room temperature and knead the dough in the two-speed dough mixer for 15 minutes. After kneading the dough, put the dough at 35°C for 60 minutes and then press it. Frozen dumplings are made after the dough skin, stuffing, freezing and other processes. The state of the frozen dumplings made by this process was subjected to sensory evaluation and freezing cracking after 10 days, 1 month, 2 months, 3 months, 4 months, 5 months and 6 months after freezing storage. Determination of rate and broken belly rate after cooking.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com