Preparation method of monosilane

A technology of monosilane and silicon tetrachloride, applied in the field of inorganic synthesis, can solve the problems of low conversion rate, loss of resin active groups, low-boiling carbon impurities, etc., and achieves the effects of high conversion rate, no catalyst, and improved utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

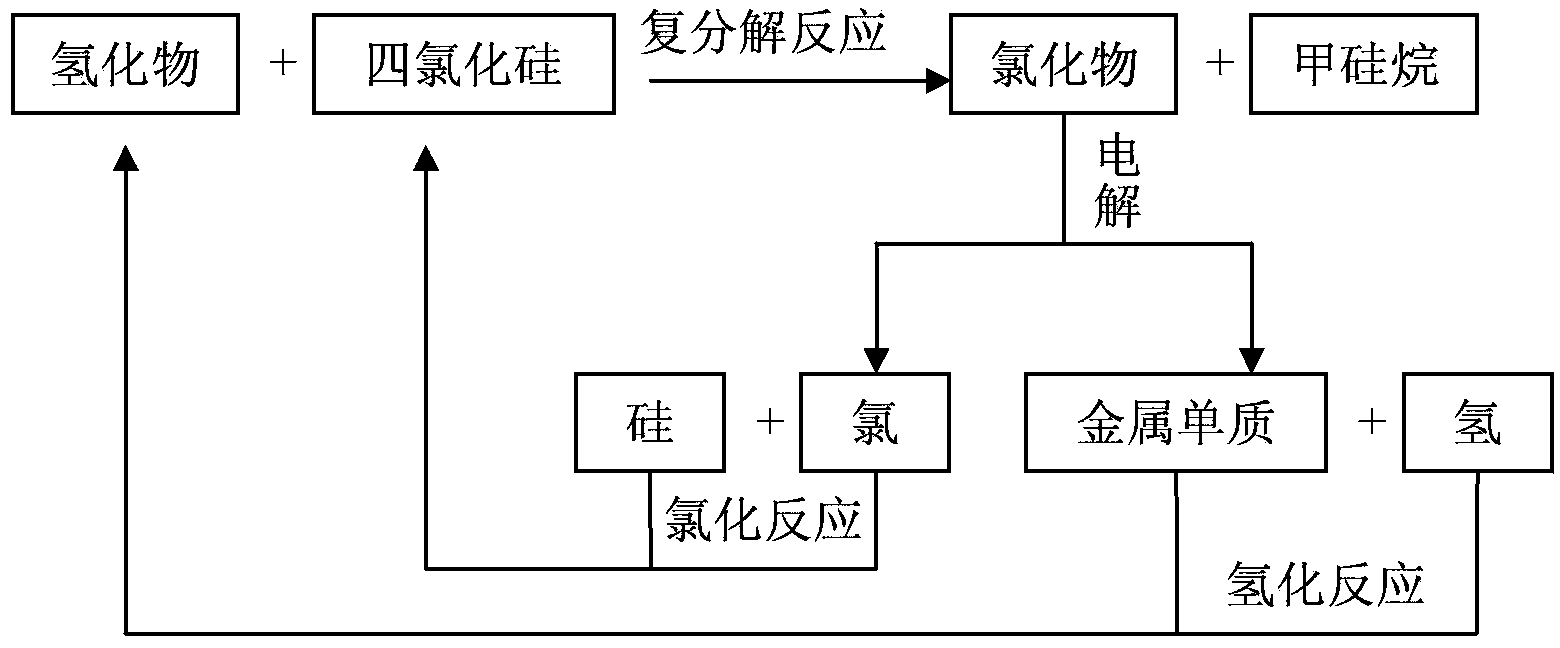

[0032] The preparation method of monosilane of the present invention, step is as follows:

[0033] A, hydride and silicon tetrachloride are carried out metathesis reaction and make monosilane and chloride;

[0034] B, the chloride electrolysis that step a obtains obtains elemental chlorine and metallic element;

[0035] c, the elemental chlorine obtained in step b reacts with metal silicon to obtain silicon tetrachloride, the metal element reacts with hydrogen to obtain a hydride, and the obtained silicon tetrachloride and hydride return to step a;

[0036] Wherein, the hydride is sodium hydride or lithium hydride.

[0037] The metathesis reaction of silicon tetrachloride and hydride is expressed by reaction formula (1), monosilane is produced in gaseous form, chloride is precipitated in the form of solid particles, and XH is used to represent the chemical formula of hydride, and the reaction formula is:

[0038] SiCl 4 +4XH→4XCl+SiH 4 (1)

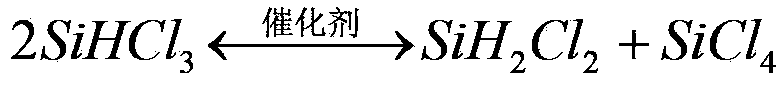

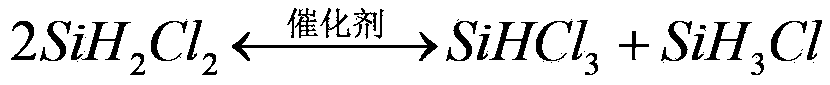

[0039] After the chloride...

Embodiment 1

[0054] Embodiment 1 adopts the inventive method to prepare monosilane

[0055] 96kg (4000mol) of sodium hydride below 100 microns was put into the reactor at one time, and then 1700kg (10000mol) of silicon tetrachloride was injected into the reactor, the temperature was raised to 50°C, and the system pressure was maintained at 0.1MPa. In the reaction, silicon tetrachloride and sodium hydride are liquid-solid reaction, and silicon tetrachloride is in liquid state. The reaction is carried out in a gap mode, and the reaction ends after about 100 hours, and the conversion rate of sodium hydride is 99.92%. A total of 22.4Nm of monosilane gas was obtained after metering 3 , Sodium chloride 234kg. Repeat above-mentioned steps 5 times, obtain the sodium chloride that is enough to be used in next step and total 1170kg. The above-mentioned sodium chloride is used for electrolysis to prepare metallic sodium and chlorine gas, and a total of 460 kg of metallic sodium and 224 Nm of chlor...

Embodiment 2

[0056] Embodiment 2 adopts the inventive method to prepare monosilane

[0057] Put 48kg (2000mol) of sodium hydride below 100 microns into the reactor at one time, then inject 255kg (1500mol) of silicon tetrachloride into the reactor, raise the temperature to 200°C, and maintain the system pressure at 3.0MPa. In the reaction, silicon tetrachloride and sodium hydride are liquid-solid reaction, and silicon tetrachloride is in liquid state. The reaction was carried out in a gap mode, and the reaction was completed after about 2 hours, and the conversion rate of sodium hydride was 99.99%. A total of 11.2Nm of monosilane gas was obtained after metering 3 , Sodium chloride 117kg. Repeat above-mentioned steps 5 times, obtain the sodium chloride that is enough to be used in next step and total 585kg. The above-mentioned sodium chloride is used for electrolysis to prepare metallic sodium and chlorine gas, and a total of 230 kg of metallic sodium and 112 Nm of chlorine gas are obtain...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com