Preparation method of trimethyl orthoformate

A technology of alcoholysis and treatment agent, which is applied in the field of preparation of trimethyl orthoformate, can solve the problems of increased side reactions of alcoholysis reaction, insufficient reaction, poor controllability of reaction, etc., and achieves mild reaction conditions, easy access to treatment agent, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

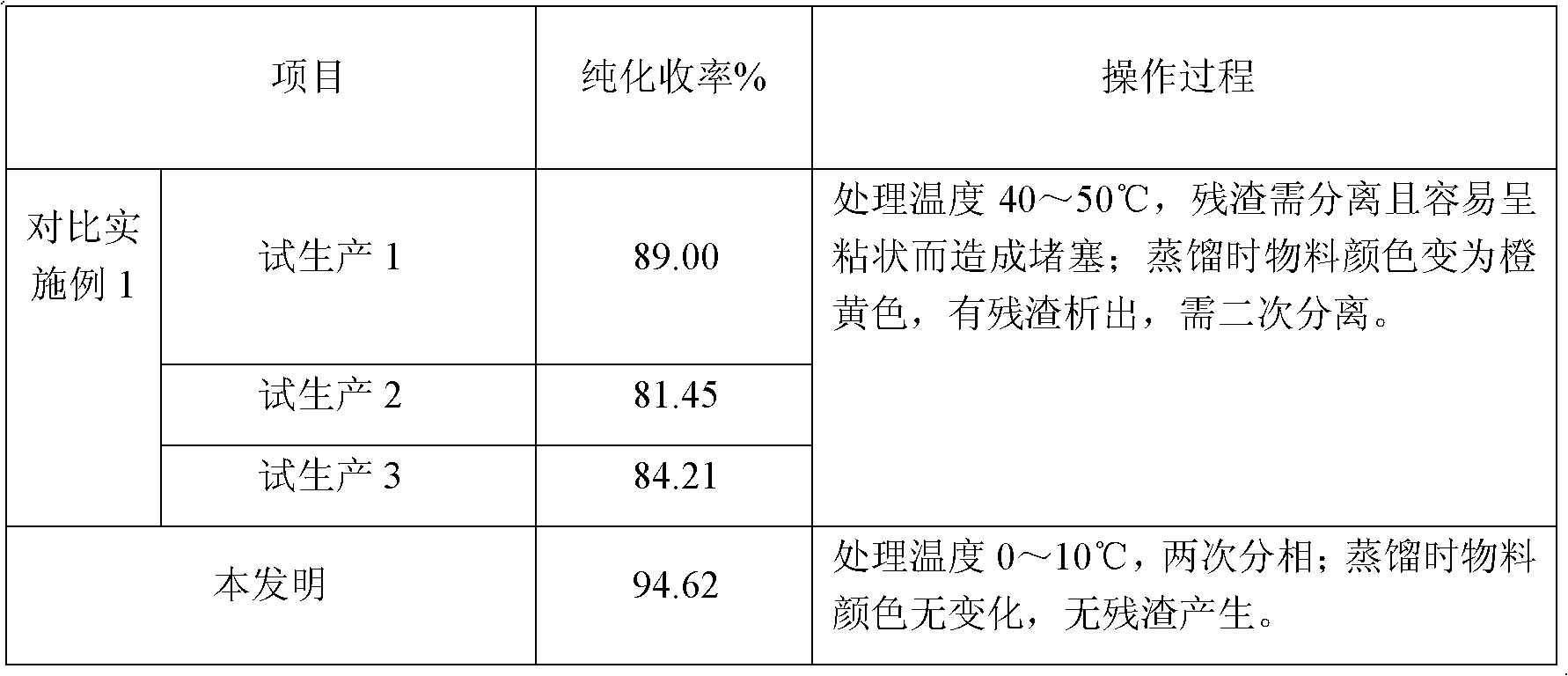

Examples

Embodiment 1

[0037] A preparation method of trimethyl orthoformate, carried out as follows:

[0038] Salt-forming process, (1), absorption of HCl: first add solvent o-dichlorobenzene (1300L, content ≥ 99%) and methanol (360L, content ≥ 99%) in the salt-forming kettle, and wait for the temperature of the salt-forming kettle to drop to At -2-2°C, start to feed excess HCl gas, and control the kettle temperature at -5-0°C during the aeration process. (2), Salt-forming reaction: After passing through HCl, add hydrocyanic acid (333L, content ≥ 99.5%), and add hydrocyanic acid for 6-14 hours, then add hydrocyanic acid to control the temperature ≤ 5°C, carry out the salt-forming reaction, add After the hydrocyanic acid is completed, heat it at -5~+5℃ and react for 2~3 hours to complete; the salt-forming liquid after the reaction is not separated from the solvent, and is directly transferred to the alcoholysis tank for the next process operation.

[0039] Alcoholysis process, (1), removal of exces...

Embodiment 2~6

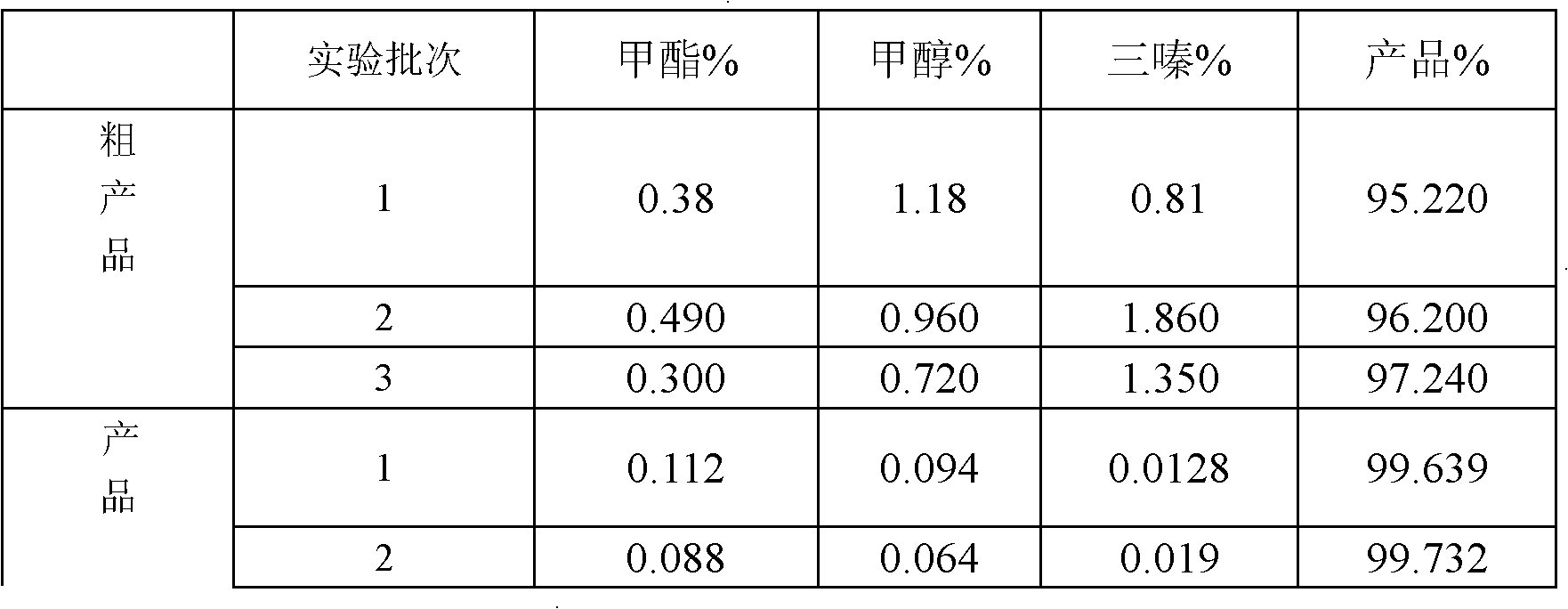

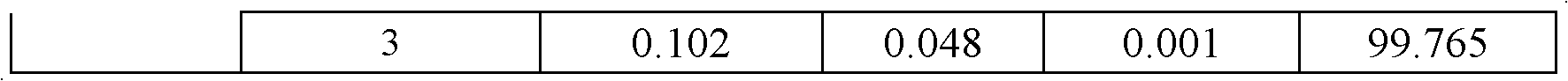

[0061] Embodiments 2 to 6: the refinement process is carried out according to the following steps and process parameters, and the others are all the same as in Embodiment 1. The prepared trimethyl orthoformate has a purity of 99.6% to 99.8% by weight, and its triazine impurity content is 0.001 to 0.06% by weight, and the yield of the following refining steps is calculated to be 90% to 96%; and there is no treatment residue generate.

[0062]

[0063] In addition, the present invention's salt-forming and alcoholysis steps can all adopt the methods in the prior art, and cooperate with the refining process described in the present invention to obtain trimethyl orthoformate with high purity and low triazine impurity content. The yield of the chemical step is high, and no treatment residue is generated.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com