Synthetic resin emulsion wall coating and preparation method thereof

A technology of synthetic resin emulsion and paint, applied in the field of paint, can solve the problems of poor wettability, permeability, dispersion, ecological environment pollution, etc., and achieve the effect of simple operation, simple process and reduced distortion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

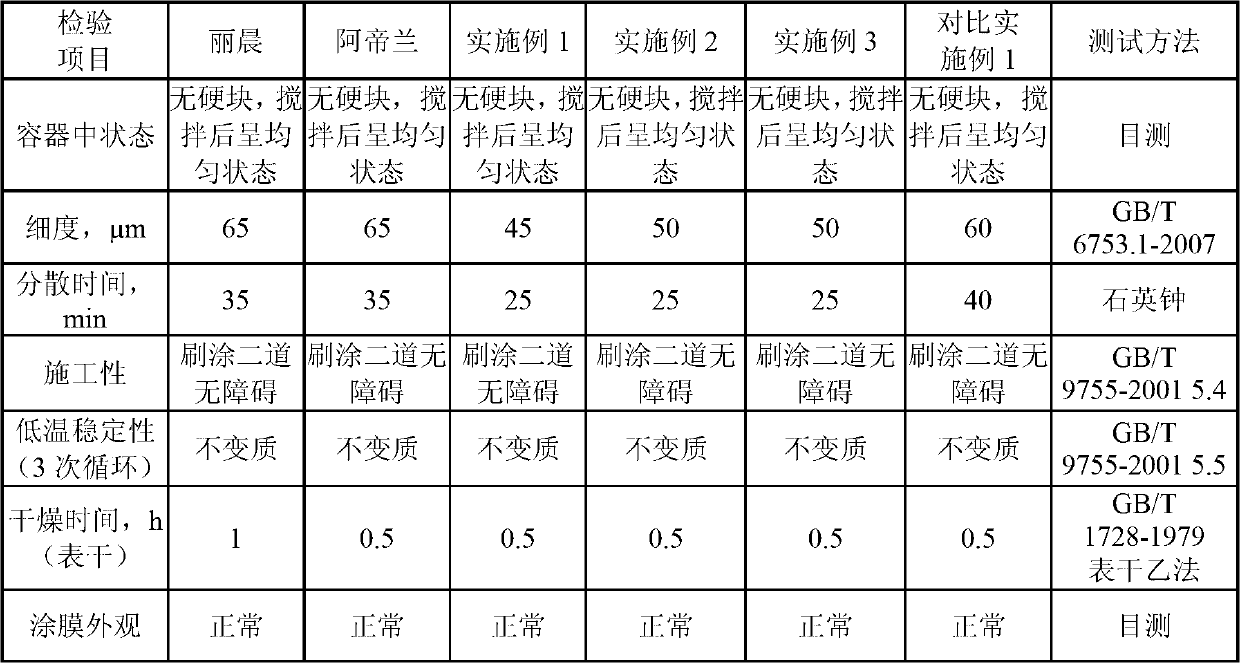

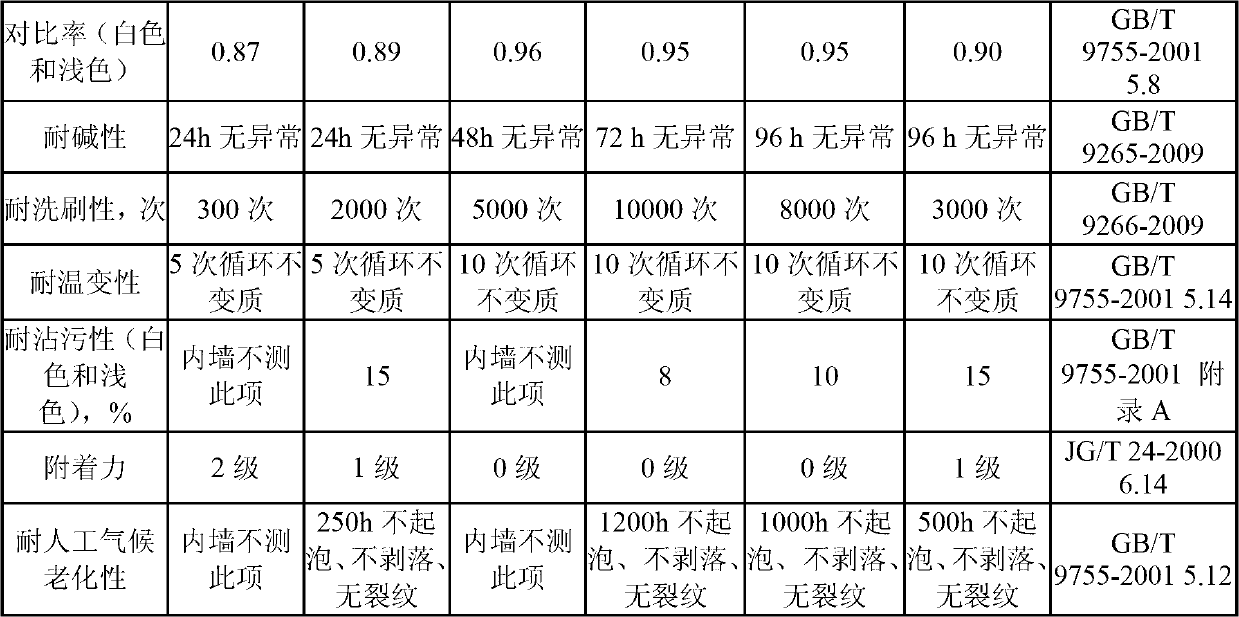

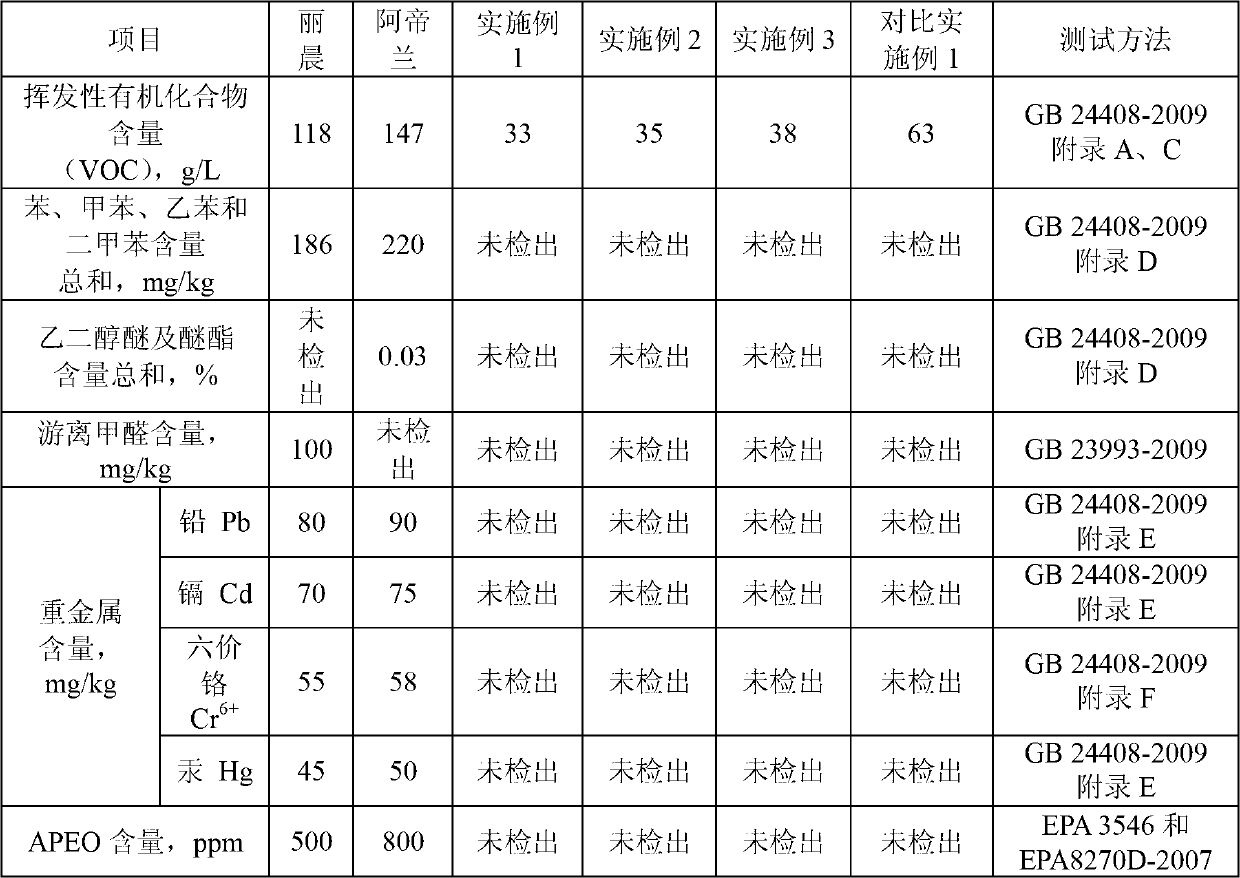

Examples

Embodiment 1

[0062] The raw material formula (wt%) of the synthetic resin emulsion interior wall paint is shown in Table 1 below.

[0063] The raw material formula (wt%) of the synthetic resin emulsion interior wall paint of table 1 embodiment

[0064] Synthetic resin emulsion Celvolit CP 3605

15.0%

Hydroxyethyl cellulose HS30000YP2

3.0%

Pigment: rutile titanium dioxide R996

20.0%

Filler: heavy calcium carbonate CC-1250

20.0%

Filler: calcined kaolin SK-T-40

12.0%

Wetting and dispersing agent CX-400

2.3%

Multifunctional additive Crosfect TM DWB-95

1.0%

[0065] Defoamer RH-900

0.5%

Thickener R278

3.2%

Crosfect GE environmentally friendly coalescent

2.0%

MIRECIDE-KW / 600 fungicide

2.4%

4.0%

Deionized water

14.6%

[0066] The preparation method of synthetic resin emulsion interi...

Embodiment 2

[0071] The raw material formula (wt%) of the synthetic resin emulsion exterior wall paint is shown in Table 2.

[0072] The raw material formula (wt%) of the synthetic resin emulsion exterior wall paint of table 2 embodiment

[0073] Synthetic resin emulsion Poligen WE-6

46.1%

Hydroxyethyl Cellulose 250HBR

1.0%

Pigment: rutile titanium dioxide R706

14.0%

20.0%

Wetting and dispersing agent Goodow 400

0.1%

Multifunctional additive CrosfectTM DWB-95

0.5%

Defoamer BD-405

0.1%

MIRECIDE-KW / 600 fungicide

1.0%

[0074] Thickener R278

1.1%

Crosfect GE environmentally friendly coalescent

1.0%

antifreeze glycol

1.1%

Deionized water

14.0%

[0075] The preparation method of synthetic resin emulsion exterior wall paint is as follows:

[0076] (1) Stir hydroxyethyl cellulose and 25.0wt% dei...

Embodiment 3

[0080] The raw material formula (wt%) of the synthetic resin emulsion universal paint for interior and exterior walls is shown in Table 3.

[0081] The raw material formulation (wt%) of the synthetic resin emulsion general-purpose coating for interior and exterior walls of the embodiment of Table 3

[0082] Synthetic resin emulsion BLJ-951

33.0%

Hydroxyethyl Cellulose HS100000YP2

1.0%

Pigment: rutile titanium dioxide R828

19.0%

Filler: calcined kaolin SK-T-40

12.2%

10.0%

Wetting and dispersing agent WA200

0.8%

Multifunctional additive CrosfectTM DWB-95

0.5%

Defoamer BD-109

0.3%

MIRECIDE-KW / 600 fungicide

1.0%

Thickener R278

2.0%

[0083] Crosfect GE environmentally friendly coalescent:

1.2%

1.0%

Deionized water

18.0%

[0084] The prepara...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap