Method of controlling temperature of energy-saving environment-friendly laterite-nickel ore smelting shaft furnace through aluminothermic process

An energy-saving and environmental-friendly technology for laterite nickel ore is applied in laterite nickel ore smelting plus on-line temperature control of aluminum particles, and in the field of laterite nickel ore energy-saving and environmentally friendly shaft furnace smelting, which can solve the problems of slow heating of smelting temperature, reduction of production efficiency, and extension of smelting time. , to save production time, improve recovery rate, and achieve good slag-making effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

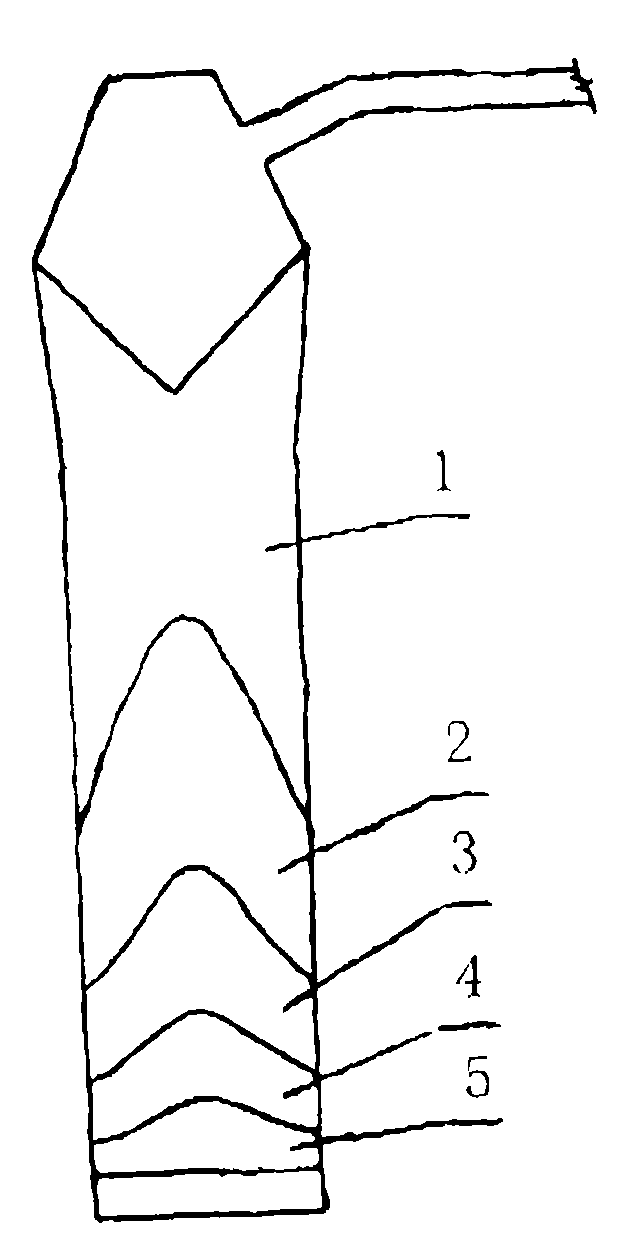

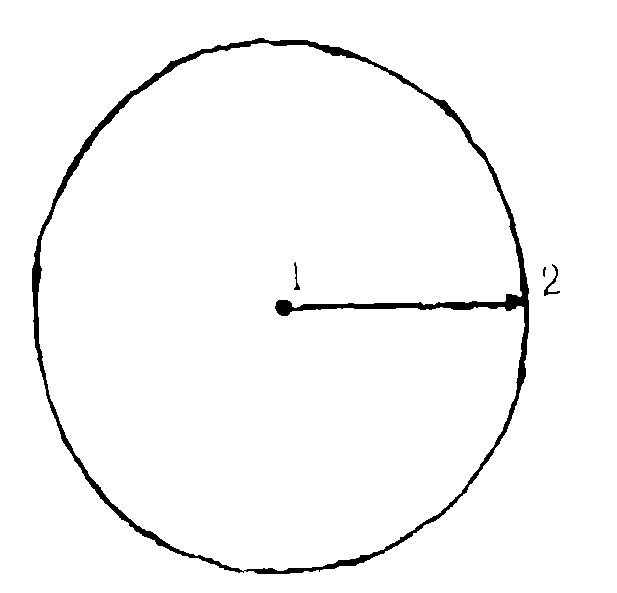

[0045] 1. Establish a temperature curve. When the temperature of the melting zone reaches 1600°C, a thermocouple is inserted into the core to represent the center of the zone for detection. Then, the thermocouple is inserted into the zone furnace lining close to the inner surface to measure the temperature, and each zone is measured in turn to calculate the temperature gradient and the corresponding The gradient coefficient of the temperature is established, and the temperature standard curve is programmed into the monitoring expert system program.

[0046] 2. During the production process, the lining temperature is detected online, and the lining temperature is compared with the curve temperature, and the deviation ideal temperature value is automatically calculated.

[0047] 3. Calculate the amount of aluminum particles to be added according to the temperature deviation value and the heat value of aluminum.

[0048] 4. Add aluminum particles to the center of the top of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com