Dyeing and finishing method of superfine denier nylon fabric

A processing method and ultra-fine denier technology, applied in the direction of dyeing method, textile and papermaking, dry cleaning fiber products, etc., to achieve the effect of no color pattern, uniform dyeing and reduction of initial dyeing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

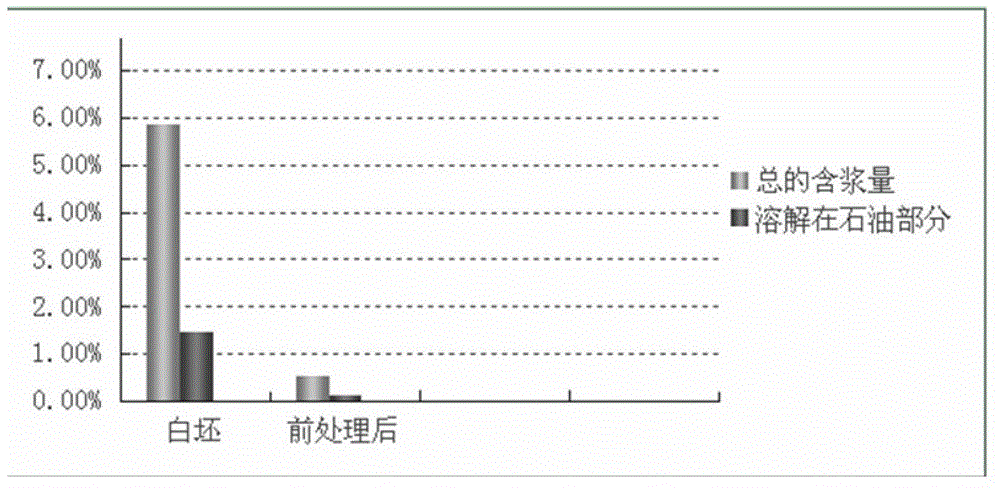

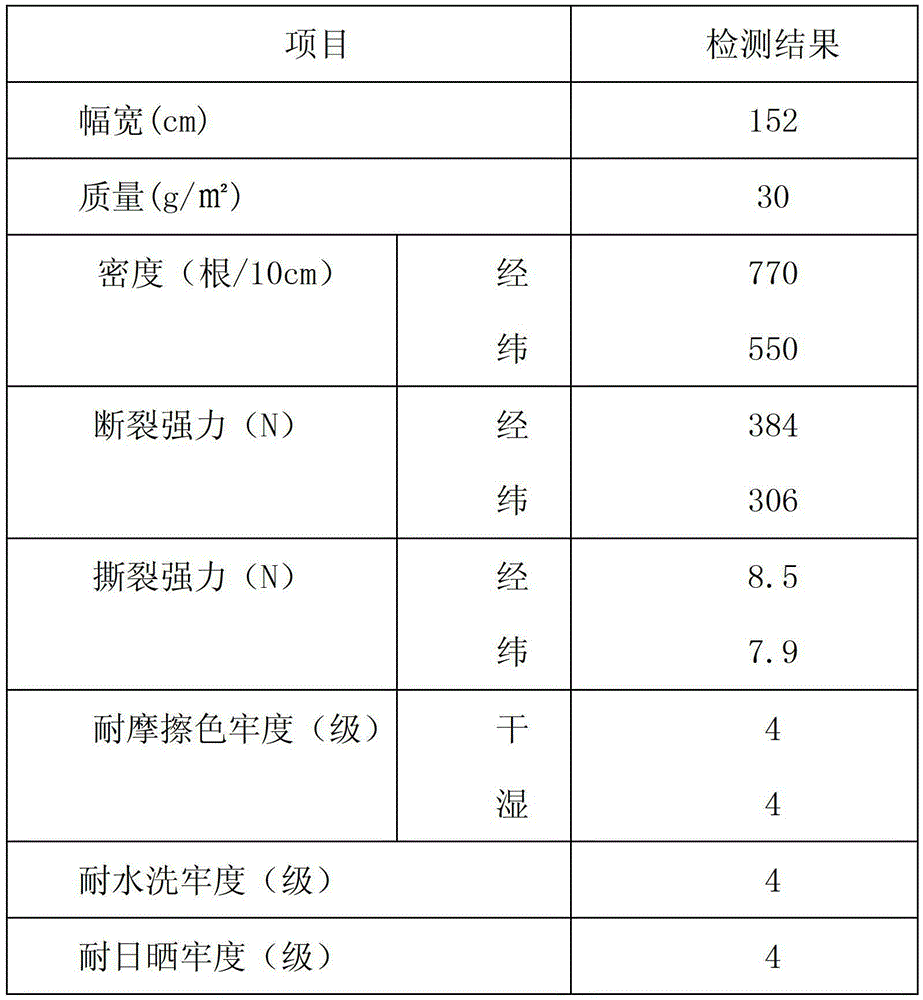

[0017] The superfine denier nylon fabric blank used in this embodiment: warp direction: 15D / 12f nylon low elastic yarn; weft direction: 20D / 24f nylon filament; door width 162cm; square meter weight 33g / ㎡.

[0018] Process flow:

[0019] Cold stacking→open width desizing→pre-setting→dyeing→fixation→drying→finishing finalized

[0020] The specific dyeing and finishing method is carried out according to the following steps:

[0021] Step 1: Cold Stack

[0022] Utilize the HLM2082 cold pile machine, under the conditions of reaction temperature of 45°C and vehicle speed of 50m / min, cold pad batch treatment is carried out on the blank of ultra-fine denier nylon fabric with cold pile liquid, wherein the cold pile liquid is oxidized by hydrogen Sodium, degreasing agent TF--126A, hydrogen peroxide, high-efficiency refining and penetrating agent TF-125D, chelating dispersant TF-133A, environmental protection low-alkali cold pile king HLD, desizing agent TF-127K and water; The concent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com