Composite negative active material, method of preparing the same, and lithium secondary battery including the same

A negative electrode active material and negative electrode technology, applied in the field of composite negative electrode active materials, its preparation method and lithium secondary batteries including it, can solve the problems of deterioration of cycle life characteristics, and achieve the effect of improving cycle life characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0079] As another aspect of the present invention, the preparation method of the composite negative electrode active material includes: heat-treating the mixture of the pore-forming agent and the carbon precursor to form a composite of the pore-forming agent and carbon; etching the pore-forming agent to form a nanoporous porous carbon; impregnating the porous carbon with a solution containing a catalyst precursor to form a catalyst-impregnated porous carbon; and introducing a metal precursor into the catalyst-impregnated porous carbon to grow metal nanostructures in the pores .

[0080] In the preparation method of the composite negative electrode active material, a mixture is formed by mixing a pore forming agent and a carbon precursor.

[0081] The pore forming agent may be silicon oxide, and for example may be SiO 2 . The pore forming agent may form nanopores having a predetermined size, and may, for example, be a powder or a particle having a size ranging from about 30 n...

preparation Embodiment 1

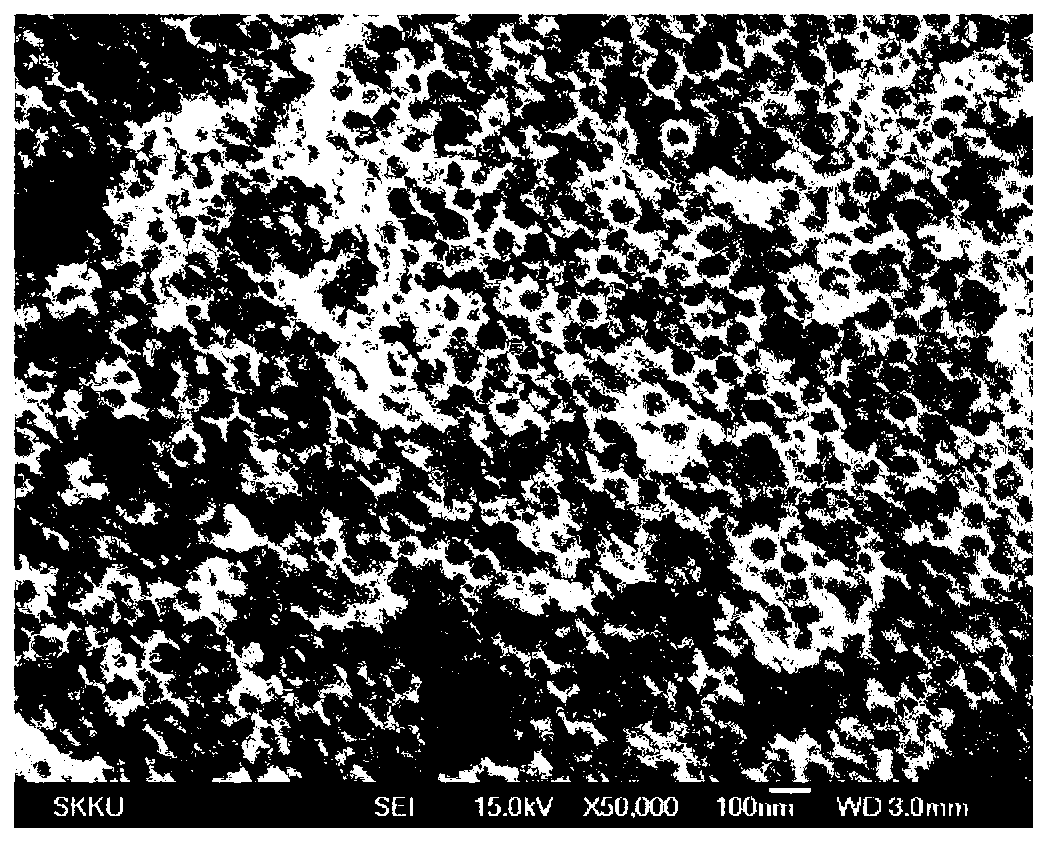

[0133] SiO with an average diameter of about 80 nm 2 The nanopowder and petroleum-based pitch (AR mesophase pitch, Mitsubishi Gas Chemical Co., Ltd.) were mixed in a weight ratio of about 50:50. The mixture was heat-treated at about 1000°C for 3-5 hours in a nitrogen atmosphere and carbonized to form SiO 2 and carbon composites. The composite was etched by immersion in a 5M NaOH solution for about 24 hours to produce a porous carbon with an average pore diameter of about 80 nm. The integrated intensity ratio D / G(I of the Raman D-line and G-line of the porous carbon 1360 / I 1580 ) is about 1.8, and the SEM micrograph of the prepared porous carbon is shown in figure 1 middle.

Embodiment 1

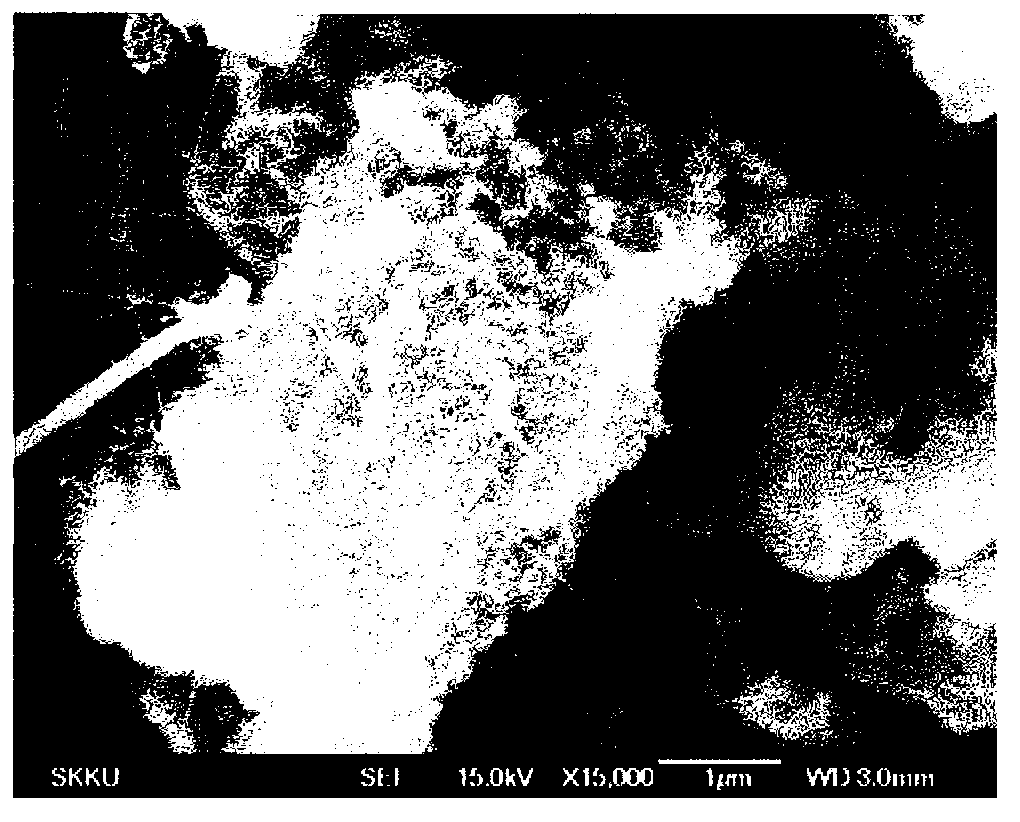

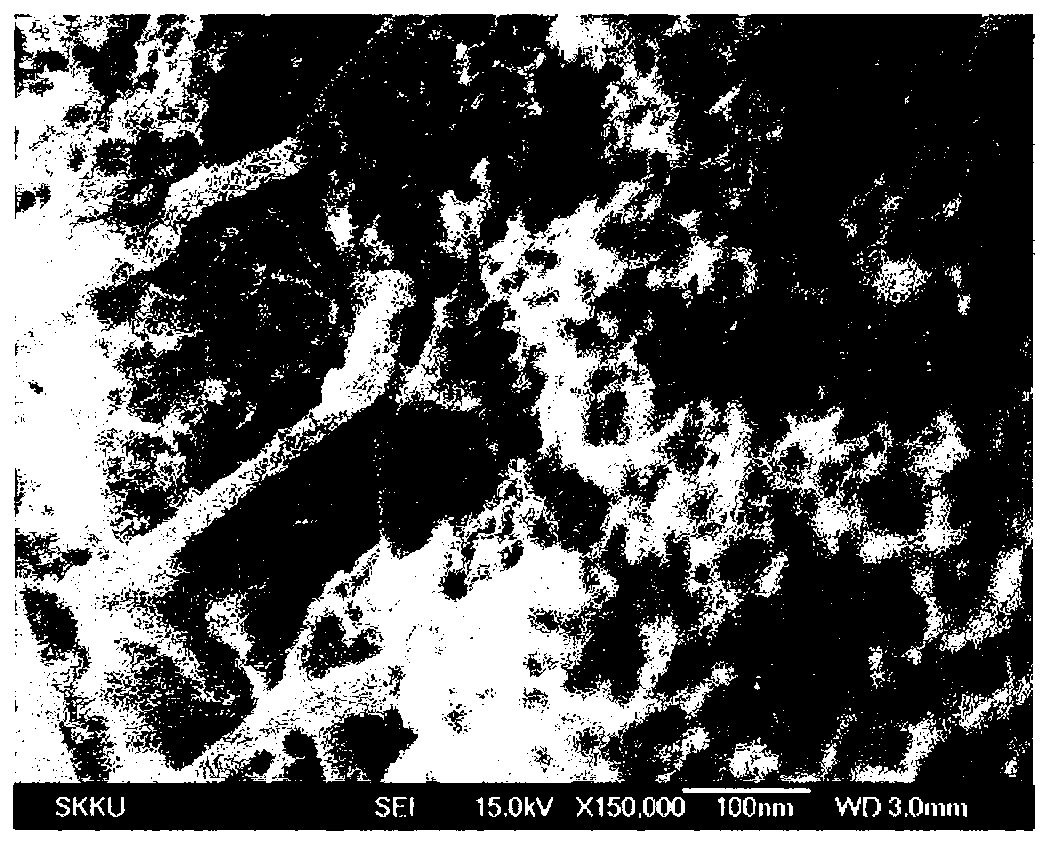

[0140] About 2 g of the porous carbon prepared in Preparation Example 1 was impregnated in about 200 cc of 0.001M HAuCl 4 (Sigma-Aldrich Corporation) in ethanol and stirred for about 24 hours. Au-impregnated porous carbon powder was then prepared by slowly drying ethanol at about 80°C and heat treating at about 500°C for about 6 hours. The porous carbon powder was placed in a small tube with holes in its front and back sides, and the holes in the two sides were plugged with quartz hairs to prevent the powder from being blown during pumping in the CVD chamber. Walk. About 10sccm silane (SiH4 , about 10% diluted H 2 gas) gas was injected into the CVD chamber to create a total pressure of about 8 Torr. A vial placed in the center of the CVD chamber was heated at about 490°C for about 5 minutes. The temperature was lowered to about 440° C. for about 10 minutes and then kept for about 2 hours to obtain a composite negative active material in which Si nanowires were grown in por...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com