Precious metal alloy composite material electrode for spark plug and manufacturing method thereof

A composite material and alloy electrode technology, applied in spark plug manufacturing, spark plugs, circuits, etc., to simplify the process, prevent falling off, and improve welding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

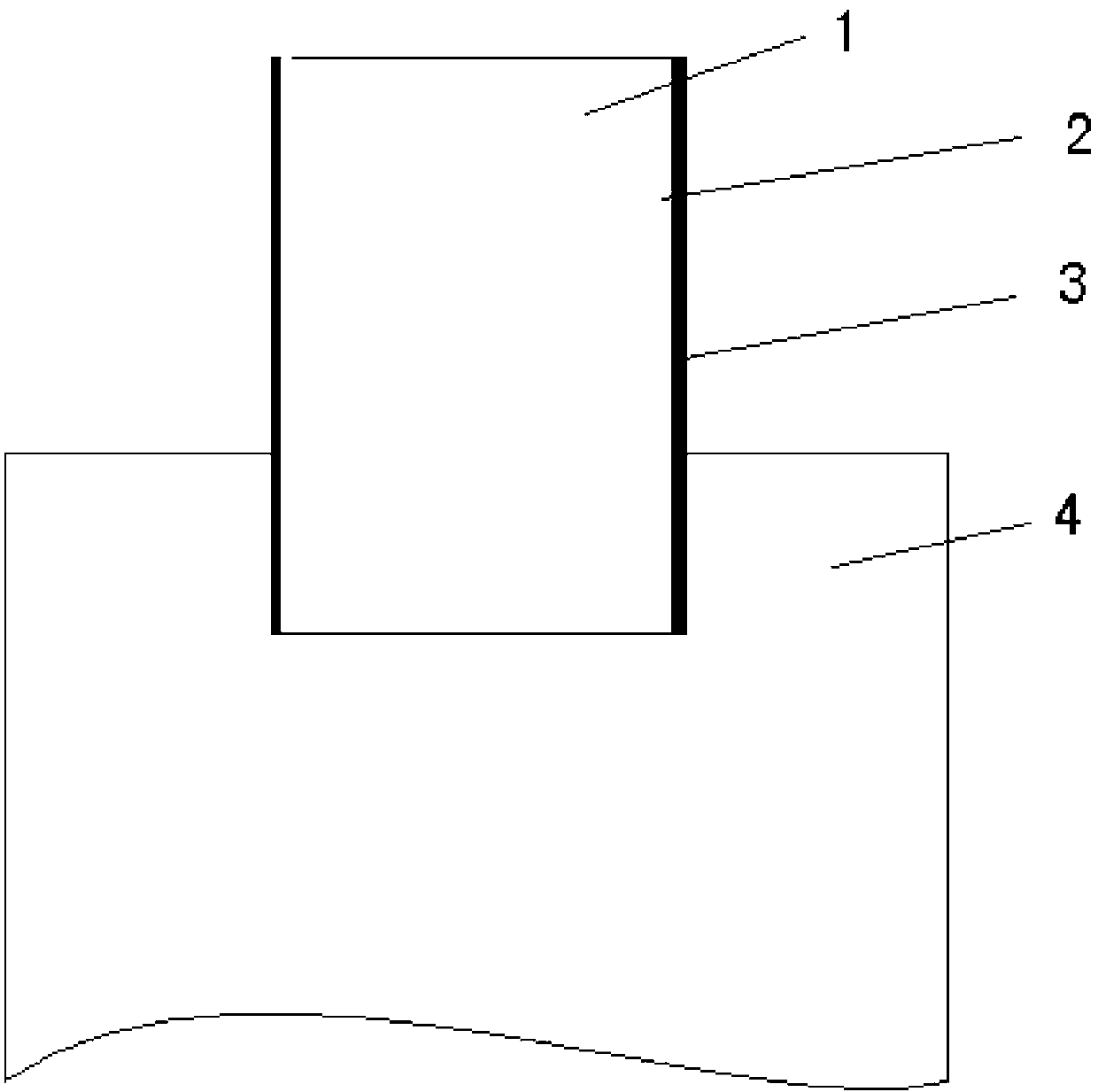

[0023] figure 1 It is a structural schematic diagram of the present invention, figure 2 It is the metallographic microscope picture of the longitudinal section of the welding longitudinal section after the resistance pressure welding of the noble metal alloy electrode substrate and the electrode base without coating the composite layer with the alloy of the base main material X as the surface layer, image 3 It is the metallographic microscope picture of the longitudinal section of the welding longitudinal section of the noble metal alloy electrode substrate and the electrode base resistance pressure welding, which is coated with the alloy of the base main material X as the surface layer, Figure 4 It is a metallographic microscope picture of the longitudinal section of the welding longitudinal section of the noble metal alloy electrode substrate and the electrode base after laser welding without coating the composite layer with the alloy of the base main material X as the su...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com