Packaging structure of intelligent power module

A technology of intelligent power modules and packaging structures, applied in the direction of support structure installation, etc., can solve the problems of long process time, high bending process requirements, and poor welding performance, so as to improve the firmness and reliability, and solve the problem of excessive contact resistance. The effect of large, good size and flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

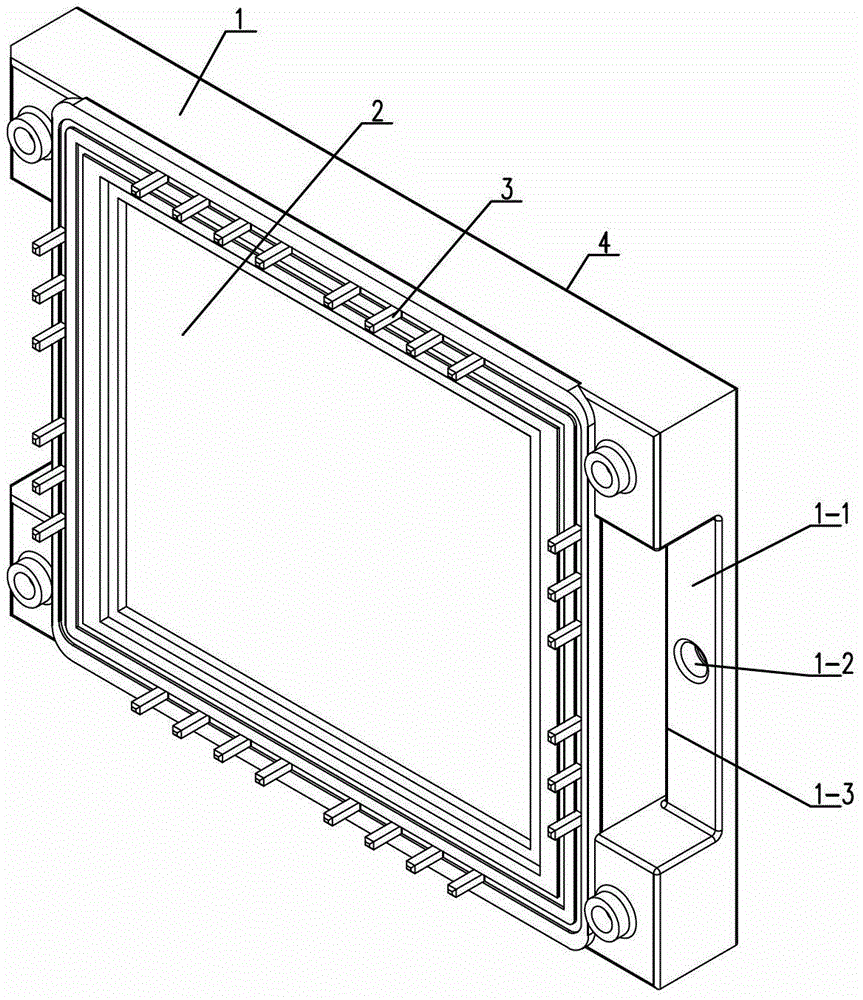

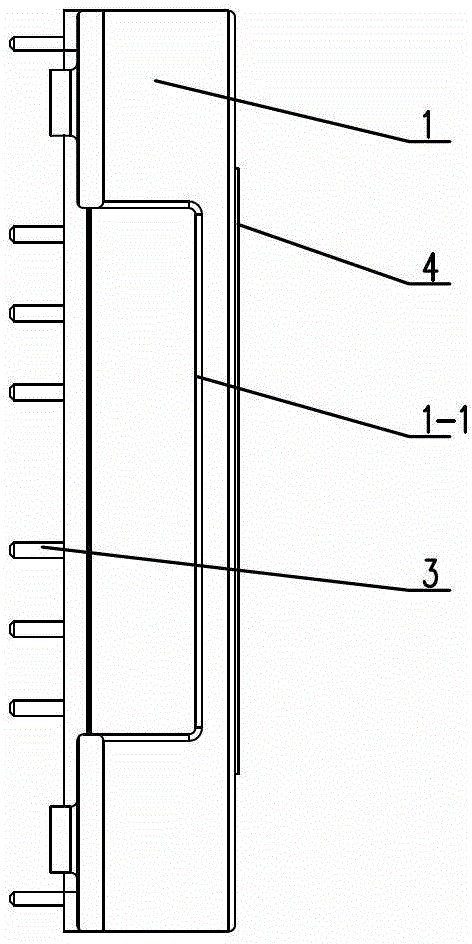

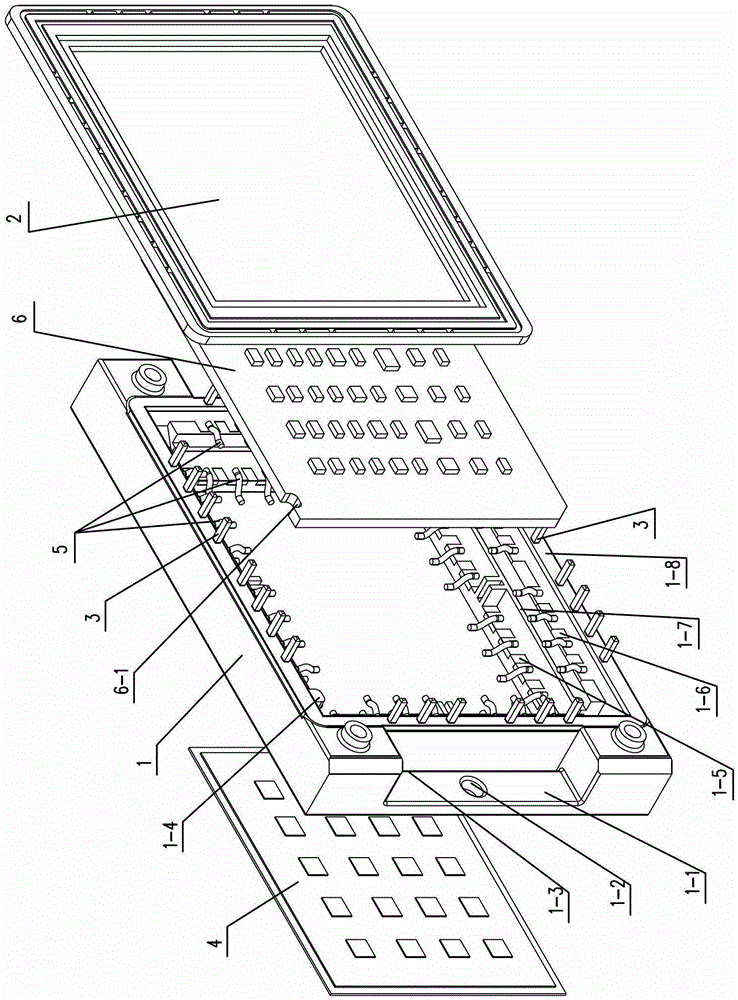

[0016] See Figure 1-3 As shown, the packaging structure of the intelligent power module of the present invention includes a housing 1, a main circuit board 4, a driving circuit board 6 and a plurality of terminals 3, and semiconductor chips, capacitors, resistors, diodes and each terminal 3 are welded on the metal-clad insulation On the metal layer of the substrate to realize circuit connection and form the main circuit board 4 for power conversion, and the driving circuit board 6 is composed of a printed circuit board and resistors, capacitors, diodes, integrated circuits, etc. welded on the printed circuit board, so as to This realizes the input and output of the drive signal. See Figure 4 As shown, each terminal 3 of the present invention is in a stepped shape, and the terminal 3 includes a vertical connecting column 3-1, an upper bonding seat 3-2 arranged at the bottom of the connecting column 3-1, and a lower bonding seat 3-2 at the bottom. 4 and the vertical connecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com