Three-way copper catalyst applied to synthesizing organic silicon monomer and preparation method thereof

A ternary copper and catalyst technology, applied in the direction of organic chemistry, chemical instruments and methods, compounds of group 4/14 elements of the periodic table, etc., can solve the problems of certain investment costs, environmental pollution, etc., and achieve low impurity content and high reaction efficiency. The equipment requirements are simple, and the effect of improving catalyst activity and selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Example 1: Preparation of a ternary copper-based catalyst for the synthesis of organosilicon monomers. The following process steps are used: crush copper oxide into raw materials with a particle size of 1-10 μm, use hydrogen and nitrogen decomposed from ammonia as reducing gases, At a temperature of 350°C, copper oxide is reduced into metal copper powder in a reduction furnace, and the reduced metal copper powder is put into a fluidized bed, and a nitrogen-oxygen mixture with an oxygen pressure of no more than 0.005MPa is passed through the bottom of the bed. After oxidizing metallic copper at a temperature of 150° C. to 250° C. for 2 hours, a finished copper catalyst containing cuprous oxide, metallic copper and copper oxide is obtained.

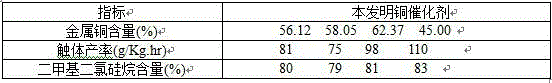

[0020] Use the above method to make multiple times continuously, obtain the ternary copper catalyst for the synthesis of organosilicon monomers, and measure the average value. Among them, the components and weight percentages are: cup...

Embodiment 2

[0021] Example 2: Preparation of ternary copper-based catalysts for the synthesis of organosilicon monomers. The following process steps are used: crush copper oxide into raw materials with a particle size of 1-8 μm, use hydrogen and nitrogen decomposed from ammonia as reducing gases, At a temperature of 350°C, copper oxide is reduced into metal copper powder in a reduction furnace, and the reduced metal copper powder is put into a fluidized bed, and nitrogen-oxygen mixed gas with an oxygen pressure not exceeding 0.010MPa is passed through the bottom of the bed, After oxidizing metallic copper at a temperature of 240° C. for 5 hours, a finished copper catalyst containing cuprous oxide, metallic copper and copper oxide was obtained.

[0022] Use the above method to make 3 times continuously, obtain the ternary copper-based catalyst for the synthesis of organosilicon monomers, and measure the average value. Copper 8.25%, after reducing the crushing particle size in the raw mater...

Embodiment 3

[0023] Example 3: Preparation of ternary copper-based catalysts for the synthesis of organosilicon monomers. The following process steps are used: crush copper oxide into raw materials with a particle size of 1-10 μm, use hydrogen and nitrogen decomposed from ammonia as reducing gases, At a temperature of 350°C, copper oxide is reduced into metal copper powder in a reduction furnace, and the reduced metal copper powder is put into a fluidized bed, and a nitrogen-oxygen mixture with an oxygen pressure of no more than 0.015MPa is passed through the bottom of the bed. After oxidizing metallic copper at a temperature of 250° C. for 7 hours, a finished copper catalyst containing cuprous oxide, metallic copper and copper oxide was obtained.

[0024] Use the above method to make 3 times continuously, obtain the ternary copper catalyst used for the synthesis of organosilicon monomer, and measure the average value. Copper 11.95%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com