Deacetylation method for chitin

A deacetylation and chitin technology, applied in the field of chitin deacetylation, can solve the problems of polluting the environment, huge cost, a large amount of waste liquid, etc., and achieve the effects of simple operation, avoiding pollution and fast reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

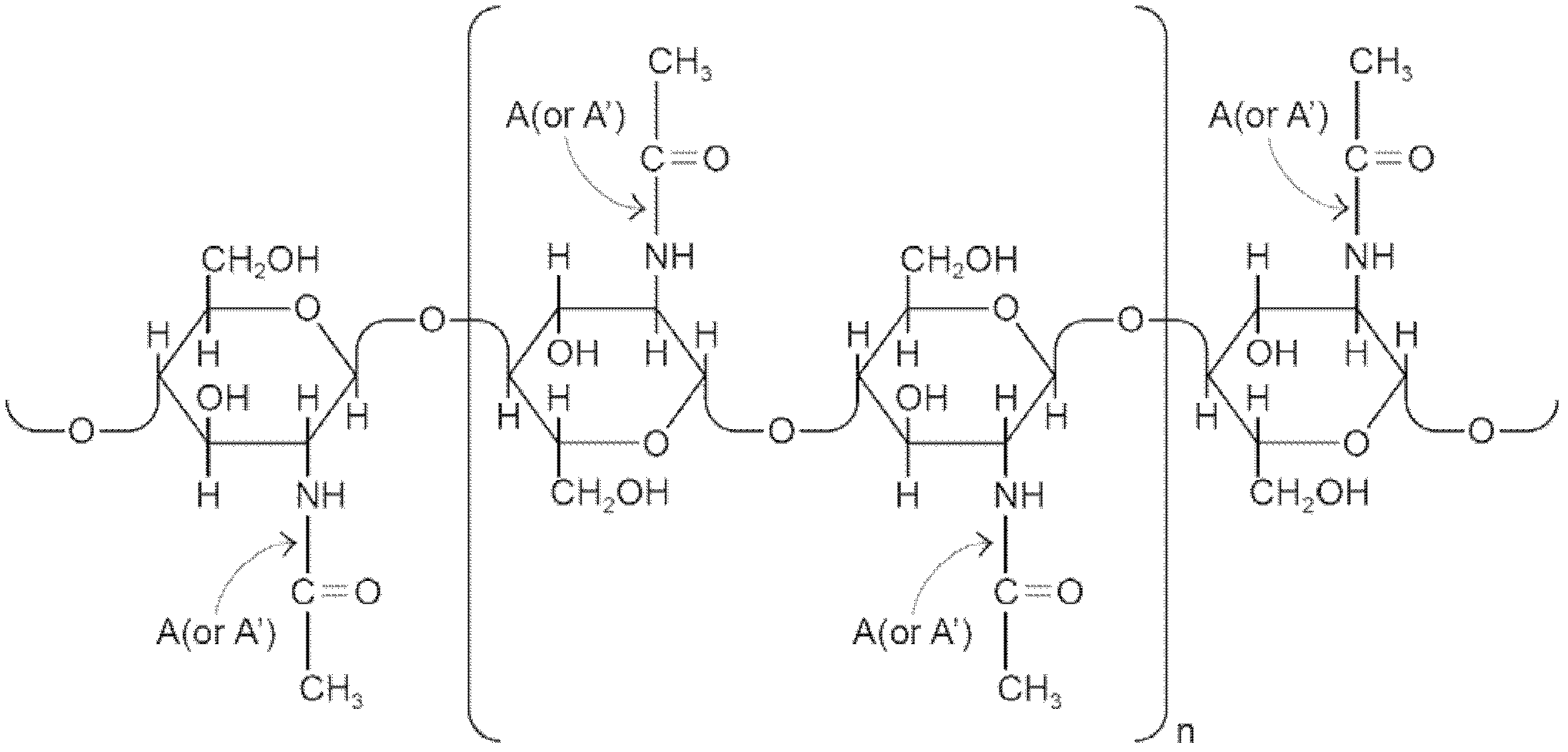

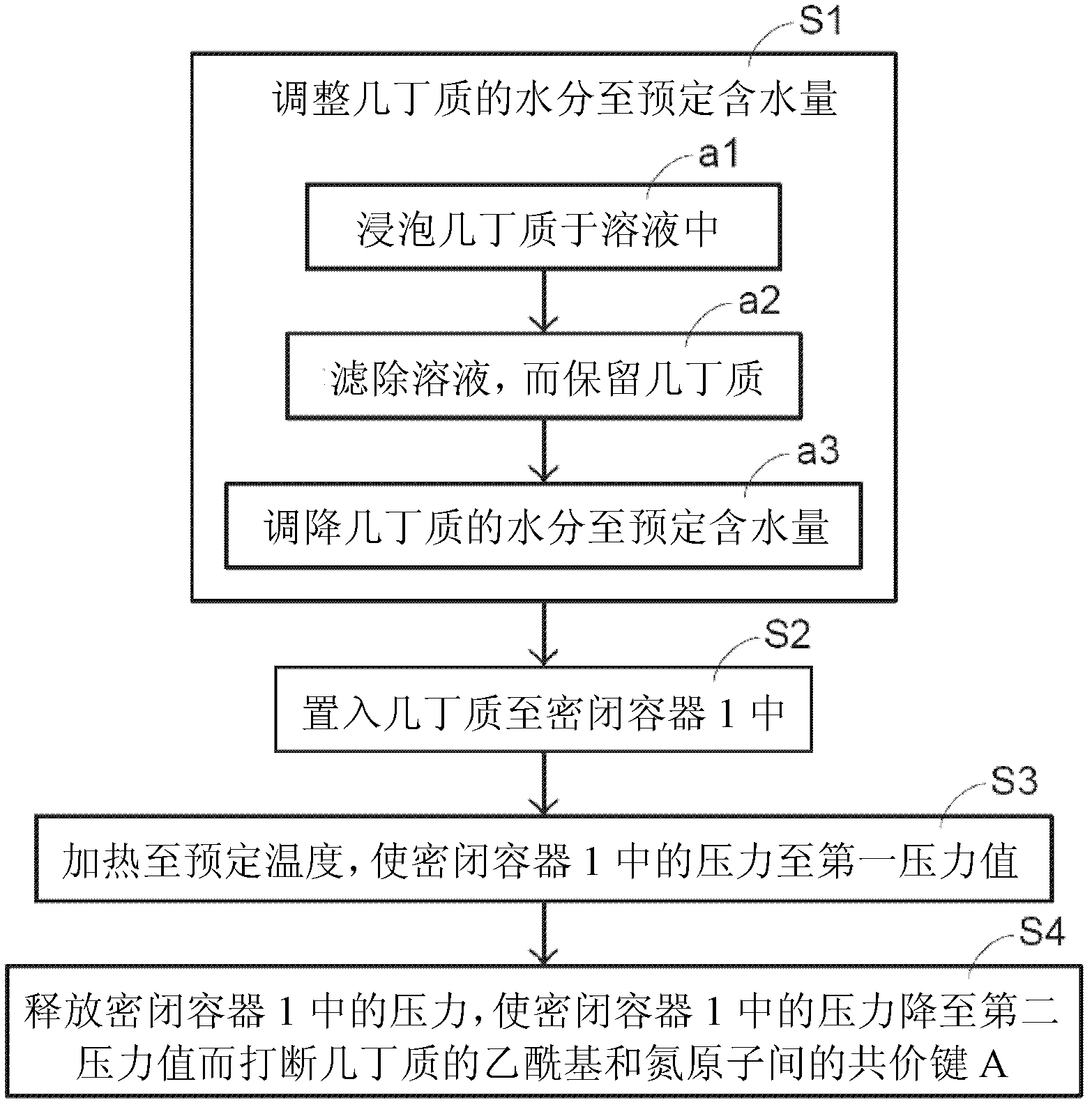

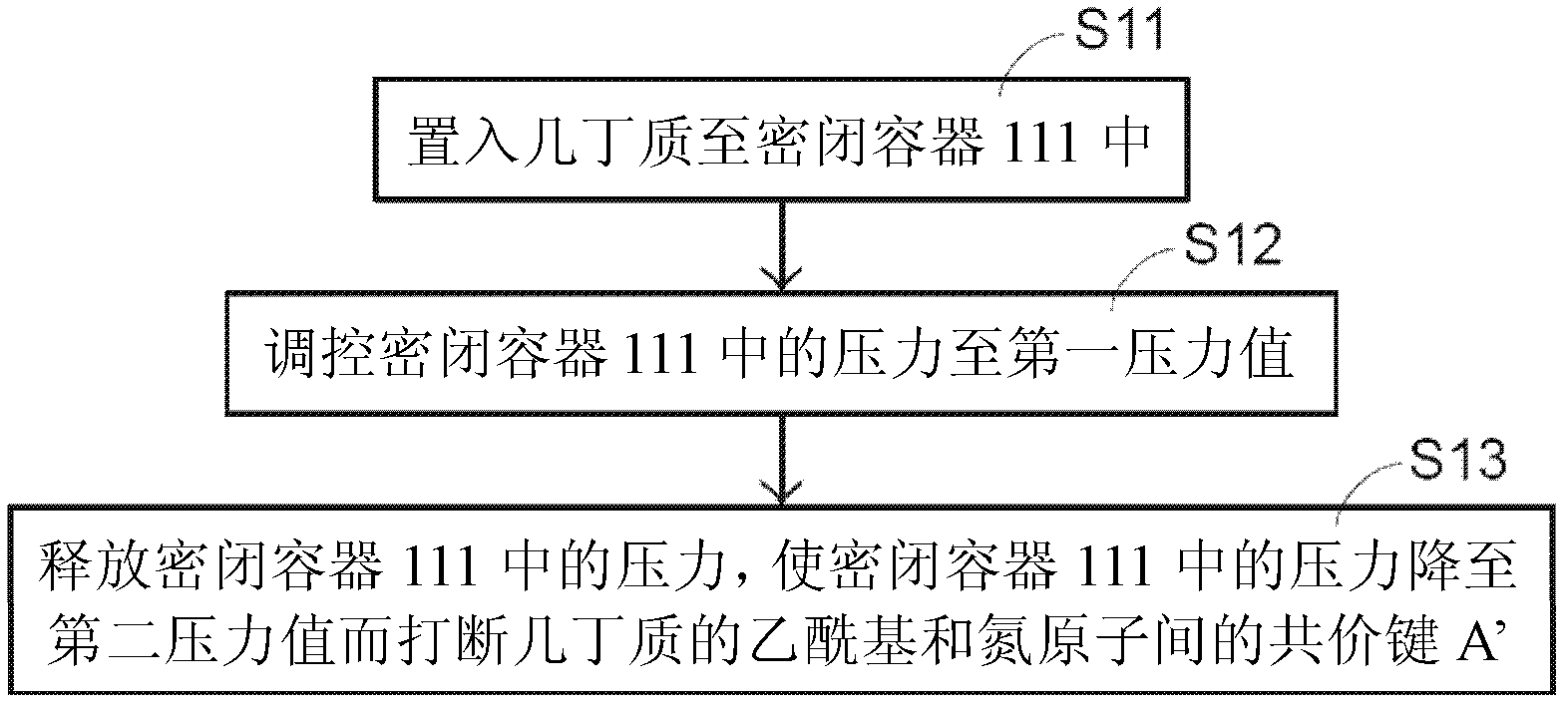

[0054] In view of the defects of the prior art, the present invention provides a new method for deacetylation of chitin, which uses high pressure to quickly return to normal pressure, and all the water in the chitin particle structure evaporates in an instant, resulting in Generate strong vapor pressure and expand rapidly in all directions. During this process, the weaker bonds in the particle structure (such as hydrogen bonds, covalent bonds between acetyl groups and nitrogen atoms) will be broken, and the vapor pressure will be controlled by These fractured pores vent.

[0055]In other words, it can be observed in the experiment that the degree of deacetylation of chitin that has been rapidly restored to normal pressure after high pressure is significantly higher than that of chitin that has not been rapidly released (p<0.05). Observation with an electron microscope revealed that after the high pressure was rapidly returned to normal pressure, the chitin particles became sma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com