Moisture-penetrable degradation chemical warfare agent composite film and its preparation method and use

A composite film and chemical warfare agent technology, applied in the field of polymer functional composite materials, can solve the problems of no protective materials, no research on degradation performance, etc., and achieve the effects of wide application fields, convenient combination molding, and reasonable functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

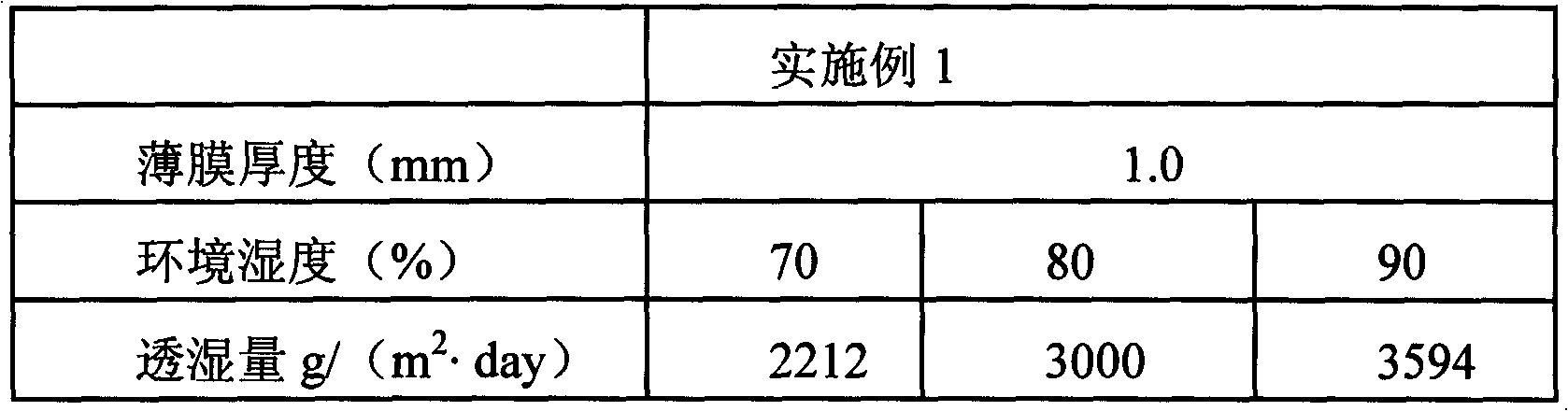

Embodiment 1

[0036] Add 10 parts by mass of N,N-dimethylaminoethyl methacrylate monomer to 0.12 parts by mass of initiator potassium persulfate to carry out monomer polymerization. The reaction temperature is 50° C. After 4 hours of reaction, a mixed solution is obtained; then 30 parts by mass of polyethylene glycol (the molecular weight of the polyethylene glycol is 2000, white solid waxy flakes, with good hydrophilic properties) is added to 150 parts by weight of water at 90 ° C and stirred to dissolve, and then the above mixed solution is dropped Mix evenly, then add 0.46 mass parts of sodium lauryl sulfate for mechanical stirring, the stirring rate is 300 rpm, and mix for 7 hours; after uniform mixing, pour it into a glass petri dish and slowly dry it under vacuum to form a film. After 24 hours of drying. A moisture-permeable degradable chemical warfare agent composite film was prepared. The thickness of the film was 1.0 mm. The moisture-permeable effects under different ambient humidi...

Embodiment 2

[0038] Add 30 parts by mass of N,N-dimethylaminoethyl methacrylate monomer to 0.15 parts by mass of initiator potassium persulfate to carry out monomer polymerization reaction at a temperature of 60°C, and react for 6 hours to obtain a mixed solution; then Add 23 parts by weight of polyethylene glycol (the molecular weight of the polyethylene glycol is 2000, white solid waxy flakes, with good hydrophilic properties) into 115 parts by weight of water at 90°C and stir to dissolve, then drop into the above mixing Mix the solution evenly, then add 0.2 sodium lauryl sulfate in mass parts for mechanical stirring, the stirring rate is 100 rpm, and mix for 8 hours; after uniform mixing, pour it into a glass petri dish and slowly dry it under vacuum to form a film , after drying for 12h. A moisture-permeable degradable chemical warfare agent composite film is prepared, and the thickness of the film is 0.07mm.

Embodiment 3

[0040] Add 60 parts by mass of N, N-dimethylaminoethyl methacrylate monomer to 0.2 parts by mass of initiator potassium persulfate to carry out monomer polymerization at a temperature of 70° C., and react for 8 hours to obtain a mixed solution; then Add 13 parts by mass of polyethylene glycol (the molecular weight of the polyethylene glycol is 2000, white solid waxy flakes, with good hydrophilic properties) into 65 parts by weight of water at 90°C and stir to dissolve, then drop into the above mixing Mix the solution evenly, then add 0.6 parts by mass of sodium lauryl sulfate for mechanical stirring, the stirring rate is 200 rpm, and mix for 7.5 hours; after uniform mixing, pour it into a glass petri dish and slowly dry it under vacuum. film, after drying for 18 h. A moisture-permeable degradable chemical warfare agent composite film was prepared, and the thickness of the film was 2.0mm.

[0041] Table 1

[0042]

[0043] Note: The moisture permeability measurement method...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com