Preparation method of high-solid content wide-temperature range damping polyurethane aqueous dispersion containing nanofiller

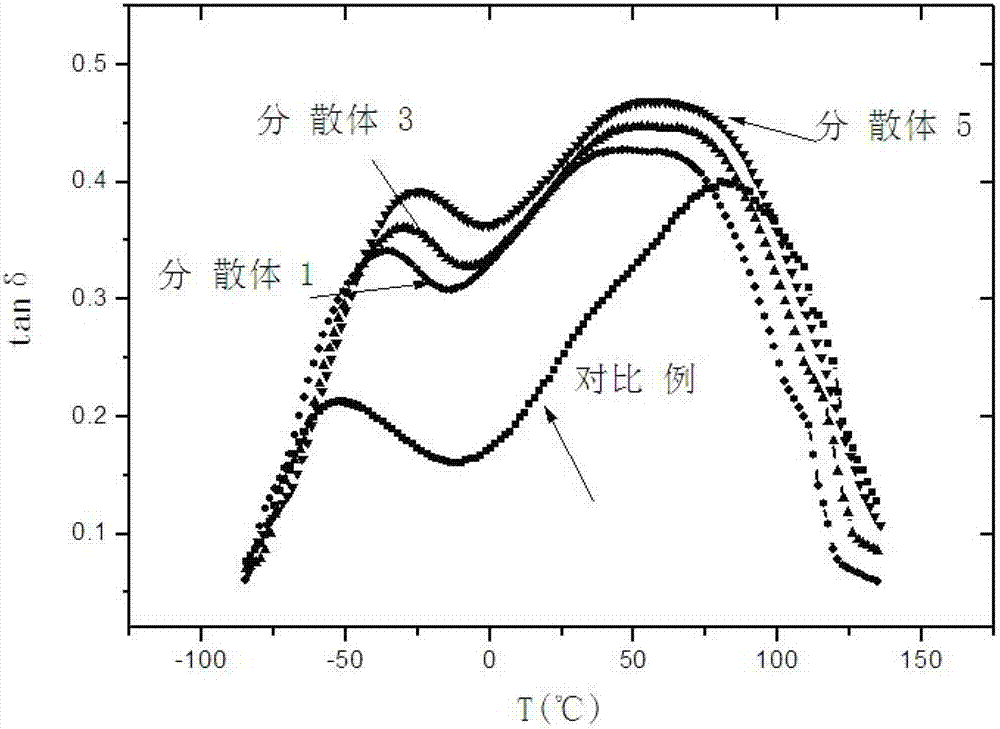

A polyurethane water dispersion and nano-filler technology, which is applied in the coating and other directions, can solve the problems of narrow temperature range, low solid content of aqueous dispersion, poor damping performance, etc., and achieve a wide application range, stable storage, and high surface energy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Weigh 122g of PTMG3k and 30.06g of PD-56 and dehydrate for 55min at a vacuum degree of 0.08MPa and a temperature of 110°C, then cool the system to 35°C and add 55.58g of IPDI, and react at a temperature of 88°C for 60min to obtain a polyurethane prepolymer (a) ; Add 9.39g DMPA and 25g dimethylformamide, add 5.9g triethylamine after continuing the reaction at 85°C for 90min at temperature control, to obtain water dispersible polyurethane prepolymer (b); weigh 160g deionized water, 1.8g foreign Emulsifier OP-10, 2.0g coupling agent KH-560, 21g nano-silicon dispersion (50%) R1050 are mixed evenly, and the polyurethane prepolymer (b) is dispersed in it under stirring state, and 1.5g of normal silicon is added dropwise after 30min The mixture of butylamine and 4.2 g of ethylenediamine was stirred continuously for 150 min to obtain dispersion 1 with a solid content of about 52.1%.

Embodiment 2

[0036] Weigh 120g of PCDL3k and 30.5g of PD-56 and dehydrate for 45min at a vacuum degree of 0.075MPa and a temperature of 120°C, then cool the system down to 35°C and add a mixture of 23.50g of HDI and 32.00g of HMDI, and react at a temperature of 75°C for 110min to obtain polyurethane Prepolymer (a); add 9.39g DMPA and 30g dimethylformamide, continue the reaction at 80°C for 130min, then add 6.1g of triethylamine to obtain water dispersible polyurethane prepolymer (b); weigh 150g to Ionized water, 1.7g external emulsifier OP-10, 2.1g coupling agent KH-560, 28g nano-silicon dispersion (50%) R1050 are mixed evenly, and the polyurethane prepolymer (b) is dispersed in it under stirring state, 30min Then, a mixture of 1.5 g of n-butylamine and 4.2 g of ethylenediamine was added dropwise, and the stirring was continued for 150 min to obtain dispersion 2 with a solid content of about 53.3%.

Embodiment 3

[0038] Weigh 118g of PTMG3k and 29.5g of PH-56 and dehydrate at a vacuum of 0.07MPa and a temperature of 125°C for 35min, then cool the system down to 35°C, add a mixture of 29.24g of HDI and 20.9g of HMDI, and react at a temperature of 80°C for 70min to obtain polyurethane Prepolymer (a); add 9.76g DMPA and 20g dimethylformamide, control the temperature at 90°C and continue to react for 70min, then add 6.5g of triethylamine to obtain water dispersible polyurethane prepolymer (b); weigh 130g to Ionized water, 1.9g external emulsifier OP-10, 1.9g coupling agent KH-550, 37g nano-silicon dispersion (50%) R1050 are mixed evenly, and the polyurethane prepolymer (b) is dispersed in it under stirring state, 30min Then, a mixture of 0.5 g of n-butylamine, 3.2 g of ethylenediamine and 1.05 g of diethylenetriamine was added dropwise, and the stirring was continued for 150 min to obtain dispersion 3 with a solid content of about 55.6%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com