Method for synthesizing one-dimensional red long afterglow material

A long afterglow material and long afterglow luminescence technology, applied in the direction of luminescent materials, chemical instruments and methods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

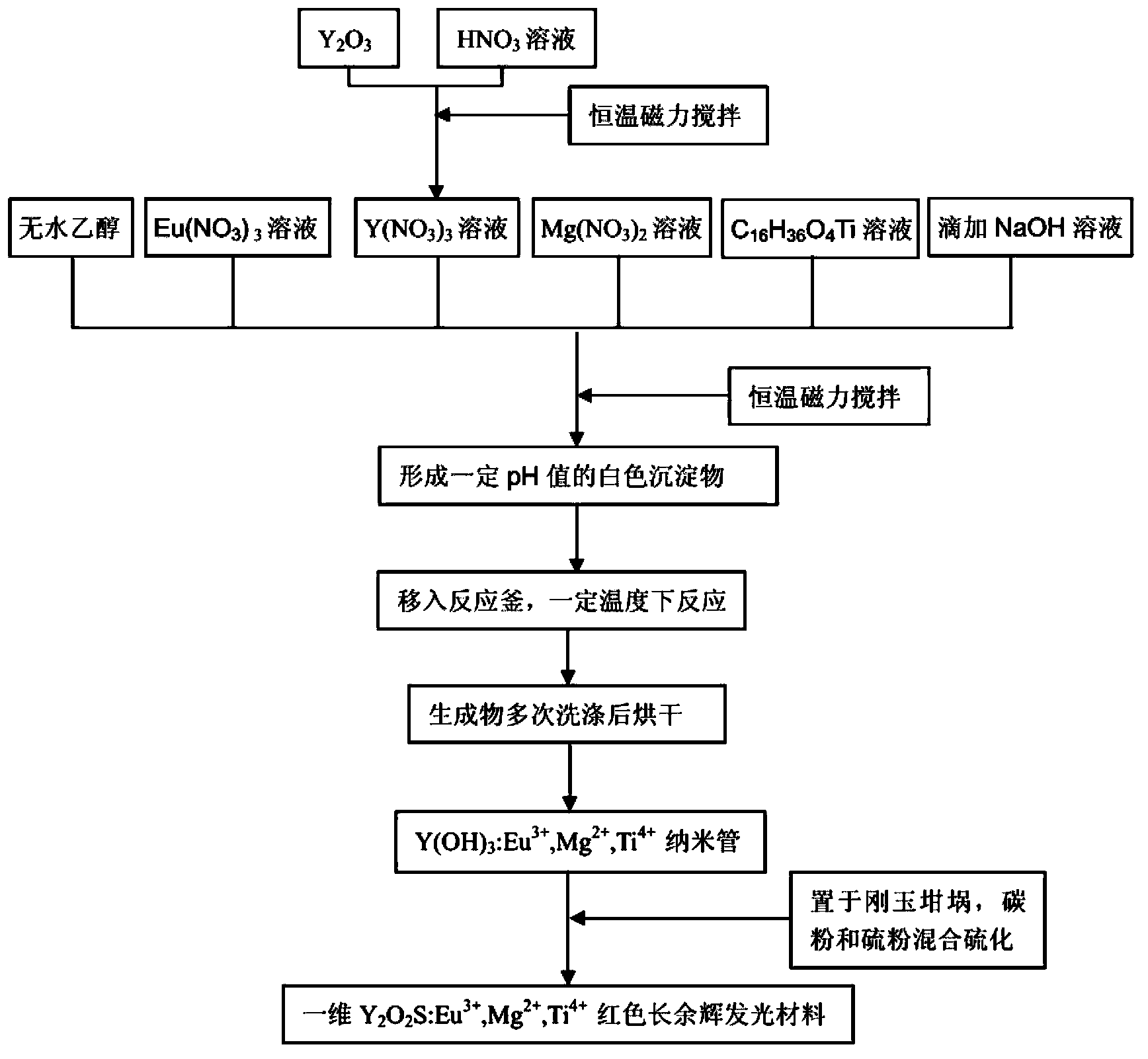

Method used

Image

Examples

Embodiment approach 1

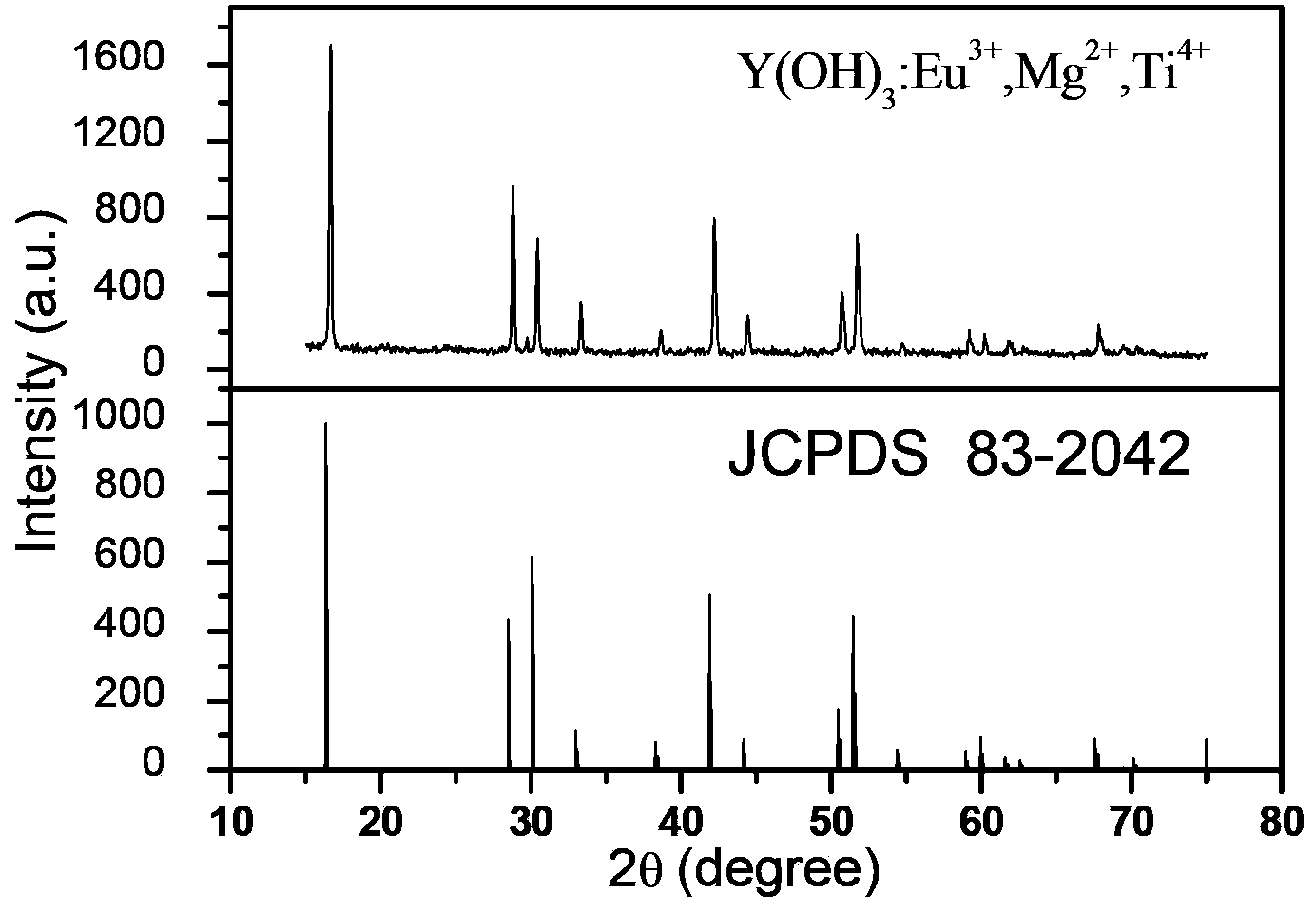

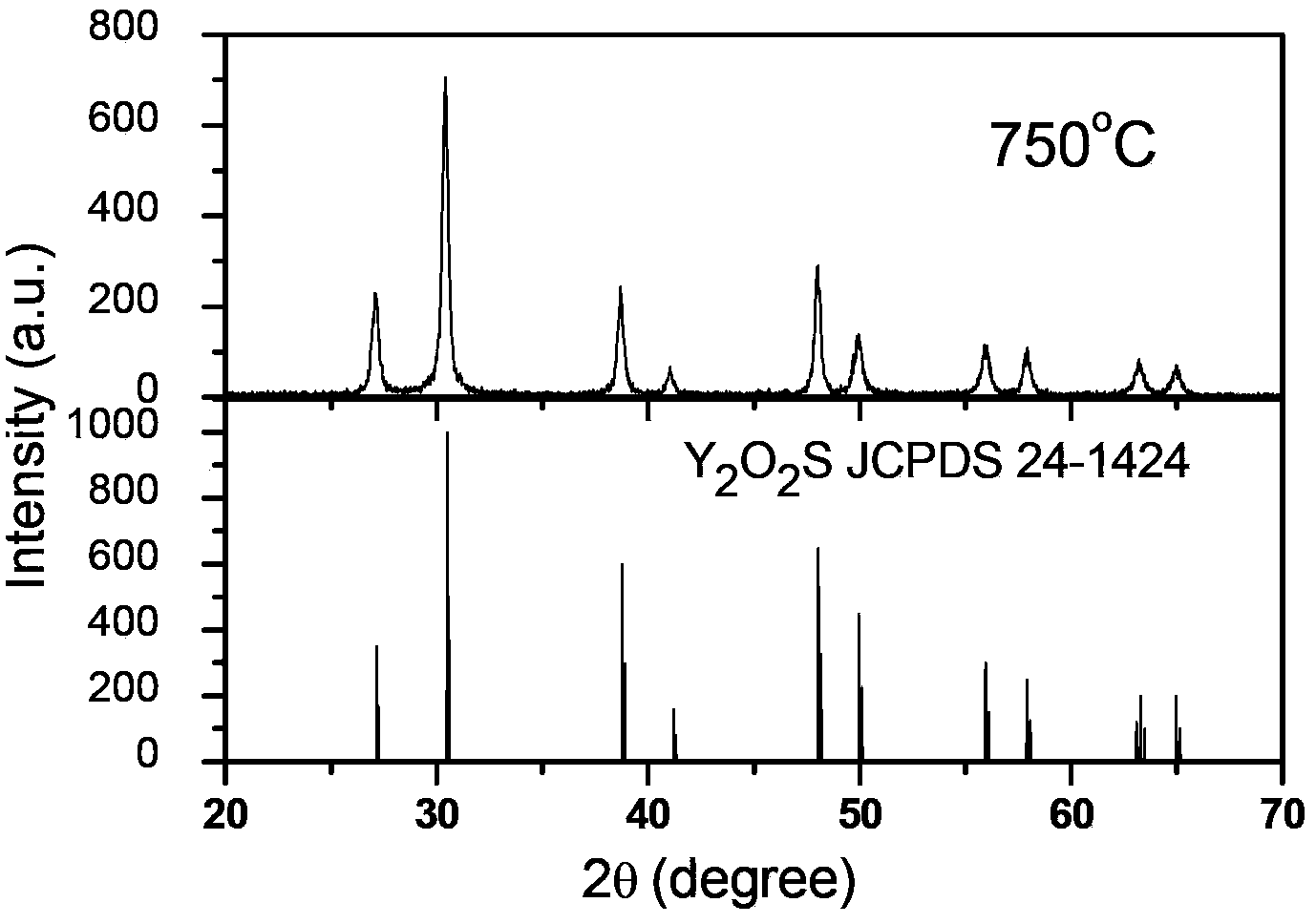

[0045] The raw material yttrium oxide, europium nitrate, magnesium nitrate, butyl titanate, nitric acid, and sodium hydroxide are configured into solutions of corresponding concentrations, and Y(NO 3 ) 3 Solution 20ml, the concentration is 0.05mol / L Eu(NO 3 ) 3 Solution 6ml, the concentration is 0.05mol / L Mg(NO 3 ) 2 Solution 2ml, the concentration is 0.05mol / L of C 16 h 36 o 4 Ti solution 2ml. After mixing the above solutions, add 42 ml of a mixture of absolute ethanol and deionized water (V 去离子水 :V 无水乙醇 =2:1). After fully stirring evenly, add 4mol / L NaOH solution to the solution to adjust the pH value to 13. Put it into a high-pressure reactor, place it in a drying oven, and heat up to 180 o C, constant temperature for 12h. Cool to room temperature, wash with deionized water repeatedly 3~4 times, oC The precursor is obtained by drying. The prepared medicine is put into a small alumina crucible, and then covered with a large crucible, and the interlayer is filled...

Embodiment approach 2

[0047] The raw material yttrium oxide, europium nitrate, magnesium nitrate, butyl titanate, nitric acid, and sodium hydroxide are configured into solutions of corresponding concentrations, and Y(NO 3 ) 3 Solution 20ml, the concentration is 0.05mol / L Eu(NO 3 ) 3 Solution 6ml, the concentration is 0.05mol / L Mg(NO 3 ) 2 Solution 2ml, the concentration is 0.05mol / L of C 16 h 36 o 4 Ti solution 2ml. After mixing the above solutions, add 42 ml of a mixture of absolute ethanol and deionized water (V 去离子水 :V 无水乙醇 =2:1), after fully stirring evenly, add 4mol / L NaOH solution to the solution, adjust the pH value to 13, put it in a high-pressure reaction kettle, put it in a drying box, and raise the temperature to 180 o C, keep the temperature for 12h, cool to room temperature, wash with deionized water repeatedly for 3~4 times, at 60 oC The precursor is obtained by drying. The prepared precursor is put into a small alumina crucible, and then covered with a large crucible, and...

Embodiment approach 3

[0049] The raw material yttrium oxide, europium nitrate, magnesium nitrate, butyl titanate, nitric acid, and sodium hydroxide are configured into solutions of corresponding concentrations, and Y(NO 3 ) 3 Solution 20ml, the concentration is 0.05mol / L Eu(NO 3 ) 3 Solution 6ml, the concentration is 0.05mol / L Mg(NO 3 ) 2 Solution 2ml, the concentration is 0.05mol / L of C 16 h 36 o 4 Ti solution 2ml. After mixing the above solutions, add 42 ml of a mixture of absolute ethanol and deionized water (V 去离子水 :V 无水乙醇 =2:1). After fully stirring evenly, add 4mol / L NaOH solution to the solution to adjust the pH value to 13. Put it into a high-pressure reactor, place it in a drying oven, and heat up to 180 o C, constant temperature for 12h. Cool to room temperature, wash with deionized water repeatedly 3~4 times, oC The precursor is obtained by drying. The prepared medicine is put into a small alumina crucible, and then covered with a large crucible, and the interlayer is filled...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com