Method for simultaneously depositing nickel-iron modified titanium dioxide nanotube electrode

A titanium dioxide, simultaneous deposition technology, applied in electrodes, nanotechnology, nanotechnology and other directions, can solve the problems of difficult to control nickel-iron atomic ratio, low deposition efficiency, etc., achieve regular morphology, reduce hydrogen evolution side reactions, and good stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

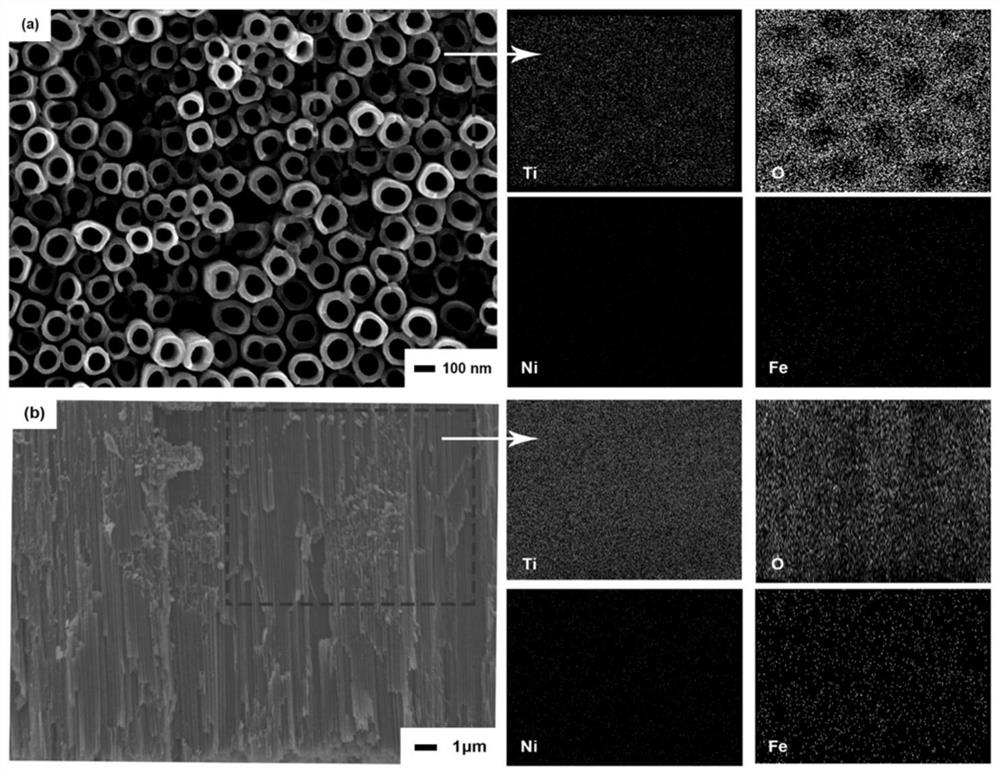

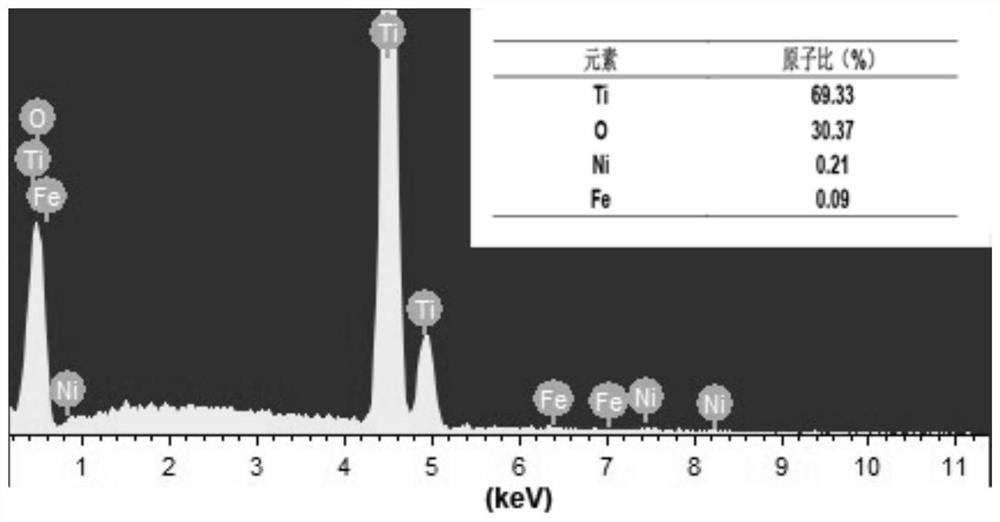

[0046] 1) The titanium foil treated with acetone, ethanol and deionized water was oxidized with a two-electrode system constant voltage, and the oxidation solution was composed of 90ml ethylene glycol, 10ml deionized water, and 2wt% (mixed solution) of ammonium fluoride. Titanium foil and platinum electrode were used as anode and cathode respectively, the oxidation voltage was 50V, and the oxidation time was 1.5h. After oxidation, it was ultrasonically cleaned for 10min, rinsed with deionized water for 30s, and then calcined in a muffle furnace at 500°C for 2h. 2°C / min to produce TiO 2 NTs photoelectrodes.

[0047] 2) Add 0.002mol FeSO 4 , 0.004mol NiSO 4 , 0.8 mmol H 3 BO 3 Dissolve 0.5mmol L-histidine in 100mL deionized water, and stir for 15min under nitrogen gas to obtain electrodeposition solution B;

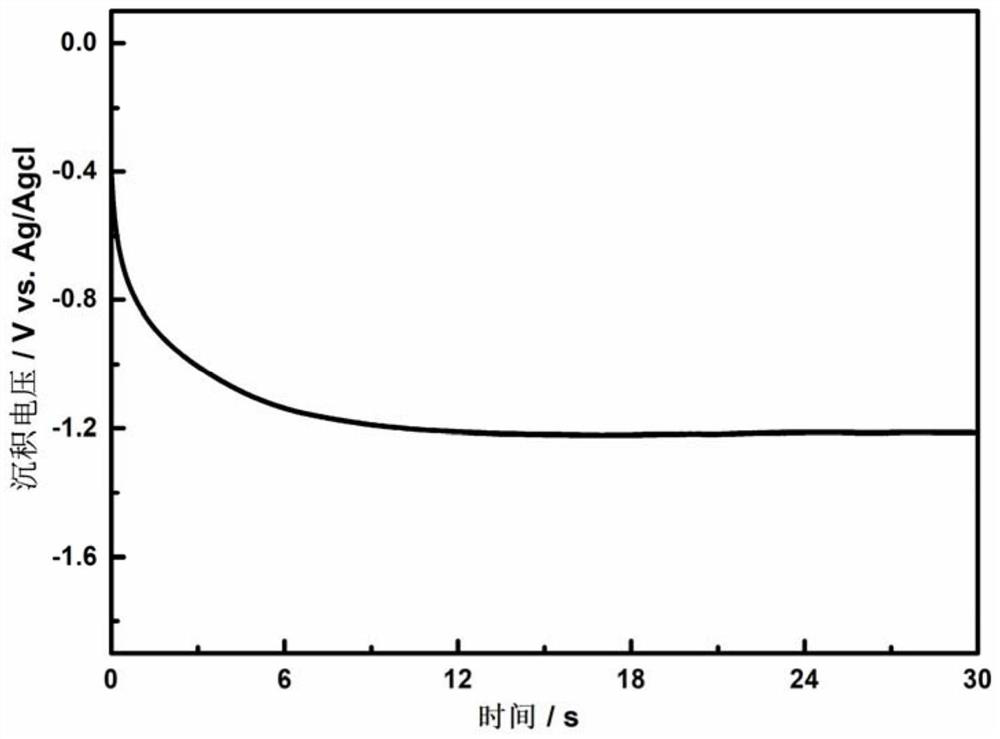

[0048] 3) wherein the titanium dioxide nanometer photoelectrode is used as the working electrode, the platinum electrode is the counter electrode, and the silver / silv...

Embodiment 2

[0052] The difference between this embodiment and Example 1 is that the concentration and ratio of Ni and Fe ions in the electrodeposition solution were changed to 3:1, the time for feeding nitrogen gas was increased from 15 minutes to 20 minutes, and the electrodeposition time was increased from 30s to 50s.

[0053] 1) The titanium foil treated with acetone, ethanol and deionized water is oxidized by a two-electrode system constant voltage method, and the oxidation solution is composed of 95ml ethylene glycol and 5ml deionized water, and 2.5wt% (mixed solution) of ammonium fluoride . Titanium foil and platinum electrode were used as anode and cathode respectively, the oxidation voltage was 50V, and the oxidation time was 1.5h. After oxidation, it was ultrasonically cleaned for 10min, rinsed with deionized water for 30s, and then calcined in a muffle furnace at 500°C for 2h. 2°C / min to produce TiO 2 NTs photoelectrodes.

[0054] 2) Add 0.002mol FeSO 4 , 0.006mol NiSO 4 , ...

Embodiment 3

[0058] The difference between this embodiment and Example 1 is that the concentration and ratio of Ni and Fe ions in the electrodeposition solution are changed to 8:3, and the deposition current density is changed from 1mA cm -2 Change to 2mA cm -2 .

[0059] 1) The titanium foil treated with acetone, ethanol and deionized water was oxidized by a two-electrode system constant voltage, and the oxidation solution was composed of 87ml ethylene glycol, 13ml deionized water, and 3wt% (mixed solution) of ammonium fluoride. Titanium foil and platinum electrode were used as anode and cathode respectively, the oxidation voltage was 50V, and the oxidation time was 1.5h. After oxidation, it was ultrasonically cleaned for 10min, rinsed with deionized water for 30s, and then calcined in a muffle furnace at 500°C for 2h. 2°C / min to produce TiO 2 NTs photoelectrodes.

[0060] 2) Add 0.003mol FeSO 4 , 0.008mol NiSO 4 , 0.8 mmol H 3 BO 3 Dissolve 0.8mmol L-histidine in 100mL deionized ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com