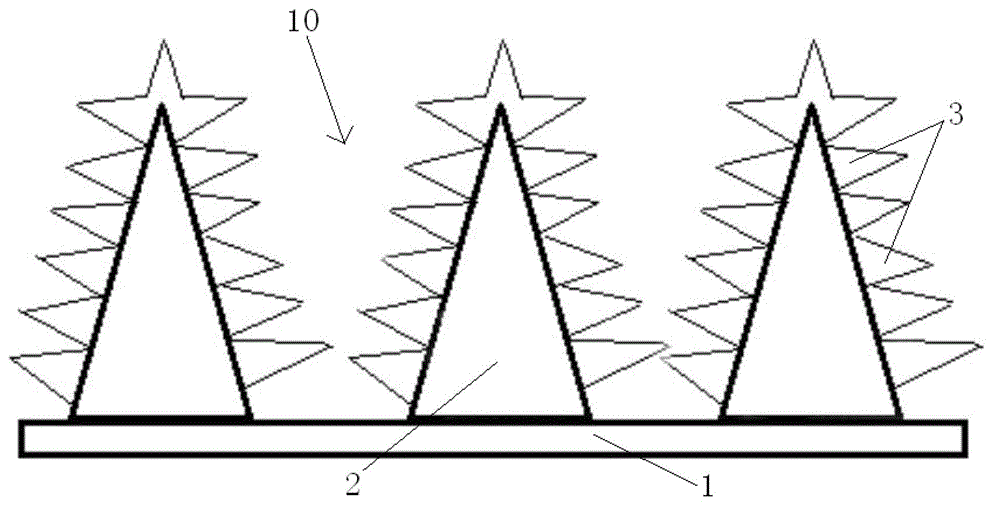

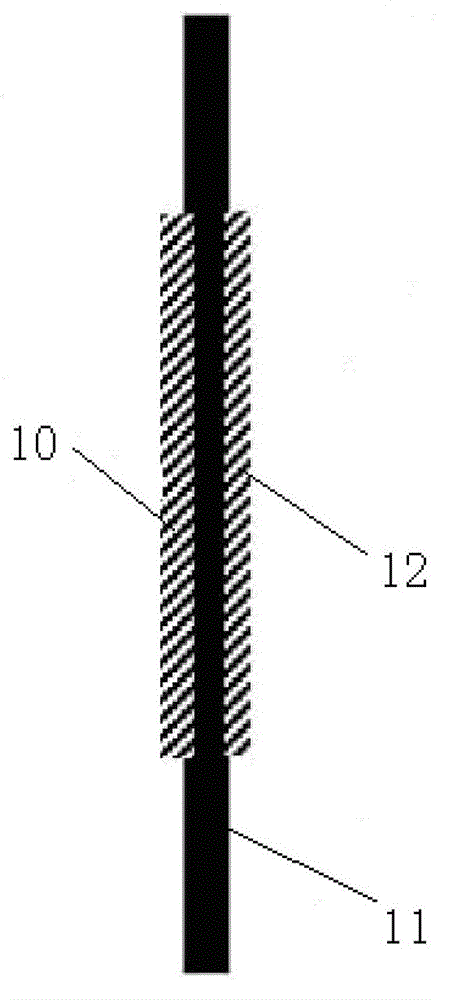

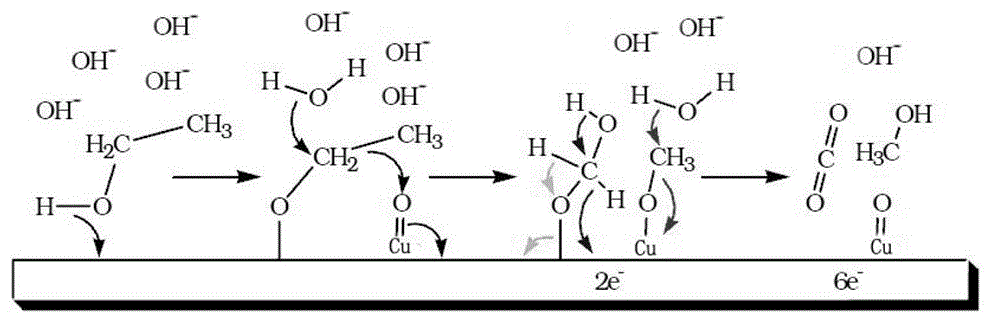

Copper oxide awl micro-level and nano-level array structure material, and preparation method and electrode apparatus thereof

A dual-stage array and structural material technology, applied in chemical instruments and methods, catalyst activation/preparation, battery electrodes, etc., can solve the problem of reducing the catalytic activity of platinum, and achieve the effects of increased specific surface area, enhanced activity, and high catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] The steps of preparing copper oxide needle-cone micro-nano bi-level array structure material are as follows.

[0039] (1) Take the copper sheet and cut it appropriately, and degrease, pickle and activate the surface of the copper sheet. That is, the copper flakes are electrolytically deoiled for 30 seconds under the condition of 5.0A / dm2, washed with distilled water, then pickled in 25% sulfuric acid for 15 seconds, washed with distilled water, and then activated in a 0.25g / L palladium chloride solution.

[0040] (2) Place the copper sheet processed in step (1) in the electroplating solution, with the copper sheet as the cathode and the copper plate as the anode. The copper sheet, the copper plate, the power supply and the electroplating solution form a current loop through the wires. The composition of the electroplating solution is: copper sulfate 10g / L, NiCl0.5g / L, boric acid 30g / L, triamine citrate 12g / L, PEG0.1g / L, sodium hypophosphite 15g / L, chloride ion 10ppm, electro...

Embodiment 2

[0047] The steps of preparing copper oxide needle-cone micro-nano bi-level array structure material are as follows.

[0048] (1) Take the copper sheet and cut it appropriately, and degrease, pickle and activate the surface of the copper sheet. That is, the copper flakes are electrolytically deoiled for 60 seconds under the condition of 4.0A / dm2, washed with distilled water, then pickled in 15% sulfuric acid for 18 seconds, washed with distilled water, and then activated in a 0.15g / L palladium chloride solution.

[0049] (2) Place the copper sheet processed in step (1) in the electroplating solution, with the copper sheet as the cathode and the copper plate as the anode. The copper sheet, the copper plate, the power supply and the electroplating solution form a current loop through the wires. The composition of the electroplating solution is: copper sulfate 20g / L, NiCl2.0g / L, boric acid 10g / L, sodium citrate 24g / L, PEG1g / L, sodium hypophosphite 10g / L, chloride ion 50ppm, plating bat...

Embodiment 3

[0056] The steps of preparing copper oxide needle-cone micro-nano bi-level array structure material are as follows.

[0057] (1) Take the copper sheet and cut it appropriately, and degrease, pickle and activate the surface of the copper sheet. That is, the copper flakes are first electrolytically deoiled under the condition of 4.5A / dm2 for 45s, washed with distilled water, then pickled in 20% sulfuric acid for 20s, washed with distilled water, and then activated in a 0.2g / L palladium chloride solution.

[0058] (2) Place the copper sheet processed in step (1) in the electroplating solution, with the copper sheet as the cathode and the copper plate as the anode. The copper sheet, the copper plate, the power supply and the electroplating solution form a current loop through the wires. The composition of the electroplating solution is: copper sulfate 15g / L, NiCl1.2g / L, boric acid 20g / L, EDTA18g / L, PEG0.5g / L, sodium hypophosphite 30g / L, chloride ion 30ppm, electroplating bath temperatu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Bottom diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com